Page 37

XC21 SERIES

Table 10. Compressor Alert Codes (A175 Main Control LEDs and Communicating Thermostat User Interface)

Outdoor A175 Main

Control LEDs

icomfort

Touch

t

Thermostat

Display

Condition

Possible

Cause(s)

Solution

Clearing Status

DS15

Yellow

DS13

Red

OFF

ON

Moderate/

Critical Alert

Code 400

Compressor

Internal

Overload Trip

Thermostat

demand signal Y1

is present, but

compressor not

running

1

Compressor protector is open.

S

Check for high head pressure

S

Check compressor supply voltage

2

Outdoor unit power disconnect is open.

3

Compressor circuit breaker or fuse(s) is

open.

4

Broken wire or connector is not making

contact.

5

Low or high pressure switch open if pres-

ent in the system.

6

Compressor contactor has failed to close.

Clears the error after

current is sensed in the

run and start winding for

two seconds, service

removed or power reset.

1 Flashes

then

Pause

OFF

Critical Alert

Code 401

Long run time.

Compressor is

running extremely

long run cycles.

1

Low refrigerant charge.

2

Evaporator blower is not running.

S

Check blower relay coil and contacts

S

Check blower motor capacitor

S

Check blower motor for failure or

blockage

S

Check evaporator blower wiring and

connectors

S

Check indoor blower control

S

Check thermostat wiring for open cir-

cuit

3

Evaporator coil is frozen.

S

Check for low suction pressure

S

Check for excessively low thermostat

setting

S

Check evaporator airflow (coil block-

ages or return air filter)

S

Check ductwork or registers for block-

age.

4

Faulty metering device.

S

Check TXV bulb installation (size,

location and contact)

S

Check if TXV/fixed orifice is stuck

closed or defective

5

Condenser coil is dirty

.

6

Liquid line restriction (filter drier blocked if

present)

.

7

Thermostat is malfunctioning

.

S

Check thermostat sub−base or wiring

for short circuit

S

Check thermostat installation (loca-

tion and level)

Clears the error after 30

consecutive normal run

cycles, or after power

reset.

2 Flashes

then

Pause

OFF

Critical Alert

Code 402

System

Pressure Trip

Indicates the

compressor

protector is open

or missing supply

power to the

compressor.

1

High head pressure.

S

Check high pressure switch if present

in system

S

Check if system is overcharged with

refrigerant

S

Check for non−condensable in system

2

Condenser coil poor air circulation (dirty,

blocked, damaged).

3

Condenser fan is not running.

S

Check fan capacitor

S

Check fan wiring and connectors

S

Check fan motor for failure or block-

age

4

Return air duct has substantial leakage.

Clears after four

consecutive normal

compressor run cycles,

or after power reset.

Summary of Contents for XC21

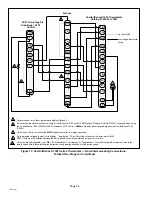

Page 21: ...Page 21 XC21 SERIES Figure 8 Typical XC21 Wiring ...

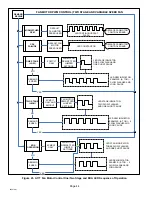

Page 39: ...Page 39 XC21 SERIES Figure 19 High Pressure Switch Operation ...

Page 40: ...Page 40 506518 01 Figure 20 Low Pressure Switch Operation ...

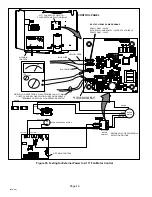

Page 41: ...Page 41 XC21 SERIES Figure 21 High Discharge Temperature Sensor Operation ...