Page 42

506518−01

Maintenance

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power

supplies.

DEALER

A175 MAIN CONTROL UNIT SIZE CODE

CONFIGURATION

In a communicating system, if the thermostat user

interface is indicating a unit size code error (see outdoor

unit installation instruction for error code) with the outdoor

main control, the following procedure must be followed to

set the unit size code using the A175 main control’s test

pins.

1. Remove 24 volts from control.

2. If leads are connected to the A175 main control’s

terminals

i−

and

i+

,

remove leads prior to starting

this procedure

.

DISCONNECT WIRES FROM

BOTH I+ AND I− TERMINALS

Figure 22. Terminals (i− and +−)

3. Place jumper on

FIELD TEST

pins (E33) (see page 22

for location of

FIELD TEST

pins).

4. Apply power to A175 control’s

R

terminal (See figure

4 for location of terminal).

5. Remove jumper from

FIELD TEST

pins (E33)

between 0−10 seconds, and then jumper again

between 0−10 seconds.

6. A175 main control’s DS11 and DS14 LEDs (see page

22 for location of LEDs) will start blinking the

Unit

Nominal Capacity Code

for 1 − 6 tons with interval of

three (3) seconds (see table 4 for codes).

7. Long blink on red LED (DS14) to indicate integer

tonnage and solid on green LED (DS11) to indicate 1/2

tonnage.

Example

: 2−1/2 ton is indicated by two long blinks on

the red LED

(DS14)

and solid on for the green LED

(DS11)

.

8. When the required LED capacity code (see table 1)

has displayed on the A175 main control,

remove the

jumper from FIELD TEST pins while the code is

still displaying.

9. The A175 main control will continue to display the

unit

nominal capacity code

until 24 volts is removed from

control.

10. Reconnect control wiring to A175 main control’s

i−

and

i+

terminals.

Table 11. Unit Size Code Display Sequence

Model

Size

Size

DS11

Green LED

DS14

Red LED

−024

2−TON

OFF

2 Long Flashes

−030

2.5−TON

ON

2 Long Flashes

−036

3−TON

OFF

3 Long Flashes

−042

3.5−TON

ON

3 Long Flashes

−048

4−TON

OFF

4 Long Flashes

−060

5−TON

ON

5 Long Flashes

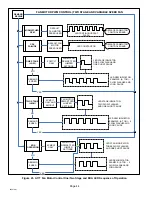

A177 FAN MOTOR CONTROL LED CODES, JUMPER

SETTINGS AND SEQUENCE OF OPERATION

During start up, the LED will first display any error

conditions (see table 14) if present. If no errors are

detected then the LED code indicating stage operation

(see table 15) will display then a long pause. The RPM

indicator is displayed next (see tables 16. After the RPM

indicator is displayed there is a short pause and the

sequence repeats if a thermostat demand is still present.

See figure 23 for LED sequence of operations. See table

15 for description of flash and pause durations.

A177 FAN MOTOR CONTROL TROUBLESHOOTING

This A177 fan motor control is used with motors which use

a Pulse Width Modulation (PWM) controller. A PWM signal

will run the fan motor at a revolutions per minute (RPM)

that corresponds to a specific PWM signal.

Verifying Jumper Settings (J2)

The unit is shipped from the factory with the default motor

RPM setting required for the specific model size. Use the

table 16 for two−stage operation to verify that jumpers are

set correctly for the specific size unit.

Verifying LED Status Codes

During start up, the fan motor control LED will

display any error conditions. If error conditions

exist then no other codes will display. If no error

conditions are present, then the stage status and

and RPM indicator are displayed.

Two−stage units

have various fan motor speed operations available (see

table 16).

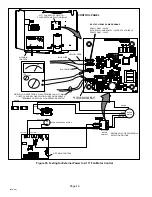

Verifying Correct DC Output Voltage (J2)

The following three methods can be used to determine

whether the fan motor is operating at the correct RPMs

based on unit size.

1. Use the information provided in table 16 to verify that

all four jumper terminals are set correctly for the

specific size unit.

Summary of Contents for XC21

Page 21: ...Page 21 XC21 SERIES Figure 8 Typical XC21 Wiring ...

Page 39: ...Page 39 XC21 SERIES Figure 19 High Pressure Switch Operation ...

Page 40: ...Page 40 506518 01 Figure 20 Low Pressure Switch Operation ...

Page 41: ...Page 41 XC21 SERIES Figure 21 High Discharge Temperature Sensor Operation ...