Step

Screw (quantity)

Color

Torque

10

M2 × L3.2 mm, flat-head, nylon-coated (3)

Yellow

0.181 Nm

(1.85 kgf-cm)

11

M1.6 × L2.8 mm, flat-head, nylon-coated (4)

Black

0.098 Nm

(1.0 kgf-cm)

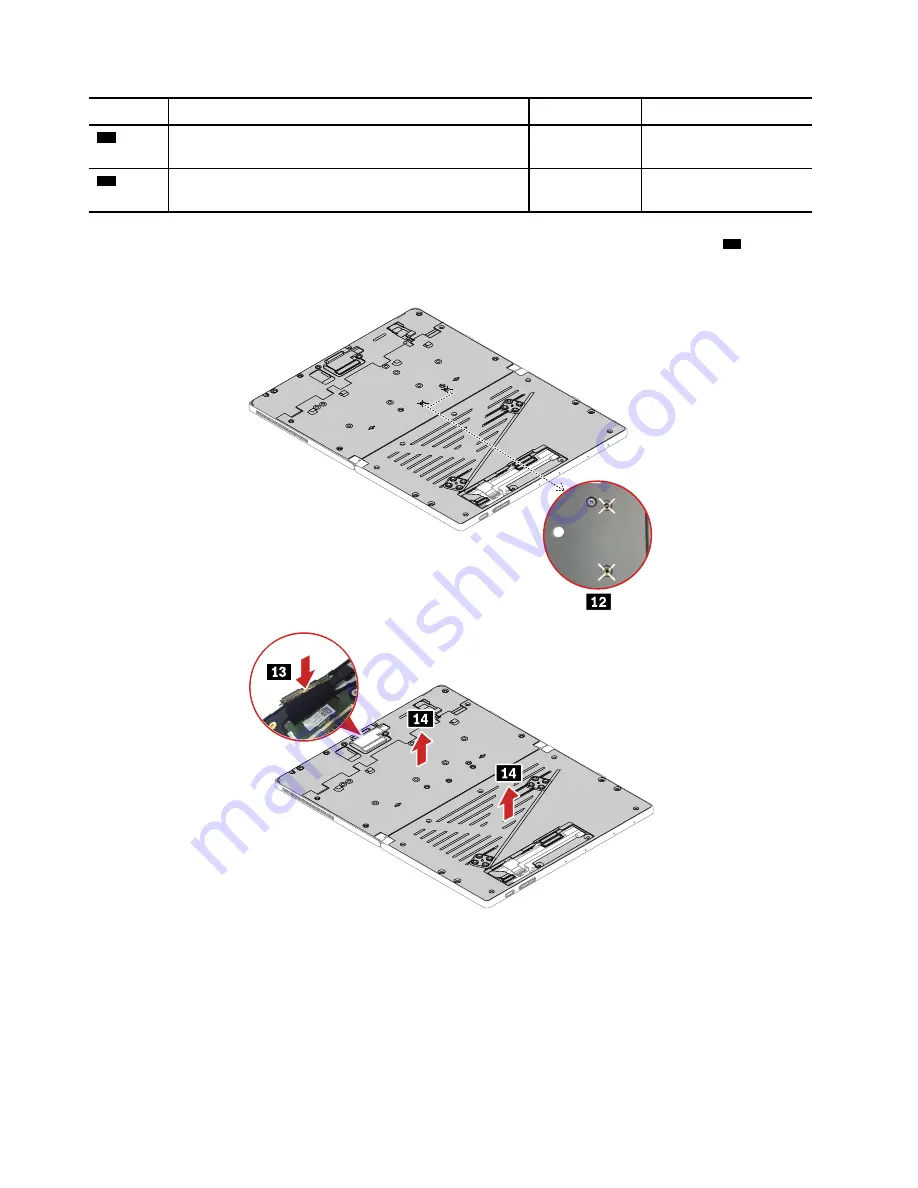

It is recommended that you install two screws (M2 × L3.5 mm) in the two slots as shown in step

12

.

Recommended screw torque is 0.098 Nm (1.0 kgf-cm). This will help you remove the system board assembly

easily.

When installing:

• Ensure that the springs on system board assembly the are fixed correctly as shown in the following

illustration.

52

Hardware Maintenance Manual

Summary of Contents for 20RK

Page 1: ...Hardware Maintenance Manual ...

Page 4: ...ii Hardware Maintenance Manual ...

Page 6: ...iv Hardware Maintenance Manual ...

Page 11: ...DANGER DANGER DANGER DANGER DANGER Chapter 1 Safety information 5 ...

Page 12: ...DANGER DANGER 6 Hardware Maintenance Manual ...

Page 13: ...PERIGO Chapter 1 Safety information 7 ...

Page 14: ...PERIGO PERIGO PERIGO PERIGO 8 Hardware Maintenance Manual ...

Page 15: ...PERIGO PERIGO PERIGO DANGER DANGER Chapter 1 Safety information 9 ...

Page 16: ...DANGER DANGER DANGER DANGER DANGER 10 Hardware Maintenance Manual ...

Page 17: ...DANGER VORSICHT VORSICHT VORSICHT VORSICHT Chapter 1 Safety information 11 ...

Page 18: ...VORSICHT VORSICHT VORSICHT VORSICHT 12 Hardware Maintenance Manual ...

Page 19: ...Chapter 1 Safety information 13 ...

Page 20: ...14 Hardware Maintenance Manual ...

Page 21: ...Chapter 1 Safety information 15 ...

Page 22: ...16 Hardware Maintenance Manual ...

Page 23: ...Chapter 1 Safety information 17 ...

Page 24: ...18 Hardware Maintenance Manual ...

Page 25: ...Chapter 1 Safety information 19 ...

Page 26: ...20 Hardware Maintenance Manual ...

Page 34: ...28 Hardware Maintenance Manual ...

Page 40: ...34 Hardware Maintenance Manual ...

Page 67: ...Chapter 7 Removing or replacing a FRU 61 ...

Page 68: ...62 Hardware Maintenance Manual ...

Page 73: ......

Page 74: ...Part Number SP40G76967 Printed in China 1P P N SP40G76967 ...

Page 75: ... 1PSP40G76967 ...