Page 14

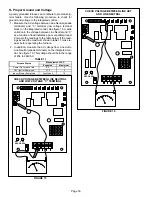

FIGURE 9

SUPPLY AIR BLOWER

AND SECONDARY LIMIT(S)

To Remove Blower From Unit: Disconnect Power, Remove

Control Box, Remove Bolts and Unplug Motor Wires From

Integrated Control. Then Slide Out Front of Unit.

SECONDARY

LIMIT (S)

CAPACITOR

MOTOR/BLOWER

ASSEMBLY

Left Side

Right Side

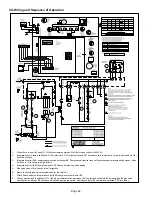

12. Blower Motors and Capacitors

All ML180UHA units use direct drive blower motors. All mo

tors are 230V permanent split capacitor motors to ensure

maximum efficiency. Ratings for capacitors will be on motor

nameplate. If replacing the indoor blower motor or blower

wheel is necessary, placement is critical. The blower wheel

must be centered in the blower housing as shown in figure

10. When replacing the indoor blower motor the set screw

must be aligned and tightened with the motor shaft as

shown in figure 11.

FIGURE 10

Center Blower Wheel

in Blower Housing

BLOWER WHEEL REPLACEMENT

FIGURE 11

Set Screw

Housing Hub

ALIGN AND TIGHTEN SET SCREW WITH

FLAT SIDE OF MOTOR SHAFT

Motor

Shaft

NOTE -

The 5 ton blower will have two flats

and two set screws 90° of each other .

13. Secondary Limit Controls

The secondary limit is located in the blower compartment in

the back side of the blower housing. See figure 9. When ex

cess heat is sensed in the blower compartment, the limit will

open. If the limit is open, the furnace control energizes the sup

ply air blower and closes the gas valve. The limit automatically

resets when unit temperature returns to normal. The secon

dary limit cannot be adjusted.

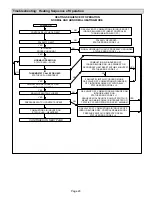

II- PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

III- START‐UP

A- Heating Start‐Up

WARNING

Shock and burn hazard.

ML180UHA units are equipped with a hot surface

ignition system. Do not attempt to light manually.

Gas Valve Operation

FIGURE 12

GAS VALVE SHOWN IN OFF POSITION

MANIFOLD

PRESSURE

OUTLET

PORT

INLET

PRESSURE

PORT

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

White Rodgers 3600 Gas Valve