Page 6

I-UNIT COMPONENTS

ML180UHA unit components are shown in figure 1.The

gas valve, combustion air inducer and burners can be ac

cessed by removing the upper access panel. Electrical

components are in the control box (figure 2) found in the

blower section.

CAUTION

Electrostatic discharge can affect elec

tronic components. Take precautions

to neutralize electrostatic charge by

touching your hand and tools to metal

prior to handling the control.

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 230V primary and a 24V sec

ondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 230VAC is wired in se

ries with line voltage. When the blower door is removed the

unit will shut down.

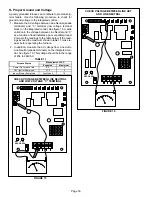

FIGURE 2

CONTROL BOX ML180UHA

Integrated Control

Door Interlock Switch

3. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box.

The switch provides overcurrent protection to the trans

former (T1). The breaker is rated 3A at 32V. If the current

exceeds this limit the breaker will trip and all unit opera

tion will shutdown. The breaker can be manually reset

by pressing the button on the face. See figure 3.

FIGURE 3

CIRCUIT BREAKER CB8

PRESS TO RESET

4. Integrated Control (A92)

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply re

place entire control.

Can cause injury or death. Unsafe operation will re

sult if repair is attempted.

The hot surface ignition control system consisting of an in

tegrated control (figure 4 with control terminal designa

tions in tables 1 and 2.) sensor and ignitor (figure 6). The

integrated control and ignitor work in combination to en

sure furnace ignition and ignitor durability. The integrated

control, controls all major furnace operations. The inte

grated control also features one LED light (AN1 red) for

troubleshooting and two accessory terminals rated at (1)

one amp. The integrated control also features a (3) amp

fuse for overcurrent protection. See table 3 for trouble

shooting diagnostic codes. The nitride ignitor is made

from a non-porous, high strength proprietary ceramic ma

terial that provides long life and trouble free maintenance.

The integrated control continuously monitors line voltage

and maintains the ignitor power at a consistent level to

provide proper lighting and maximum ignitor life.