8400 StateLine C | Reference manual

Motor control (MCTRL)

Braking operation/brake energy management

226

L

Firmware

≤

11.00 - DMS 8.0 EN - 10/2011

5.11.2

Selecting the response to an increase of the DC-bus voltage

If the brake chopper threshold resulting from

C00173

and

C00174

is exceeded in the DC

bus, the reaction selected in

C00175

takes place (use of the brake resistor and/or stop of

the ramp function generator and/or inverter motor brake).

Optimum following of the actual speed value until the speed setpoint is reached (e.g.

the motor is stopped rapidly) is always achieved with the help of a brake resistor.

Stopping the ramp function generator enables smoother deceleration with lower

torque oscillation..

From version 04.00.00

, the inverter motor brake is available for selection in

C00175

.

This function enables rapid braking without a brake resistor. Torque oscillations can

occur due to the traversing dynamics.

Inverter motor brake

(

228)

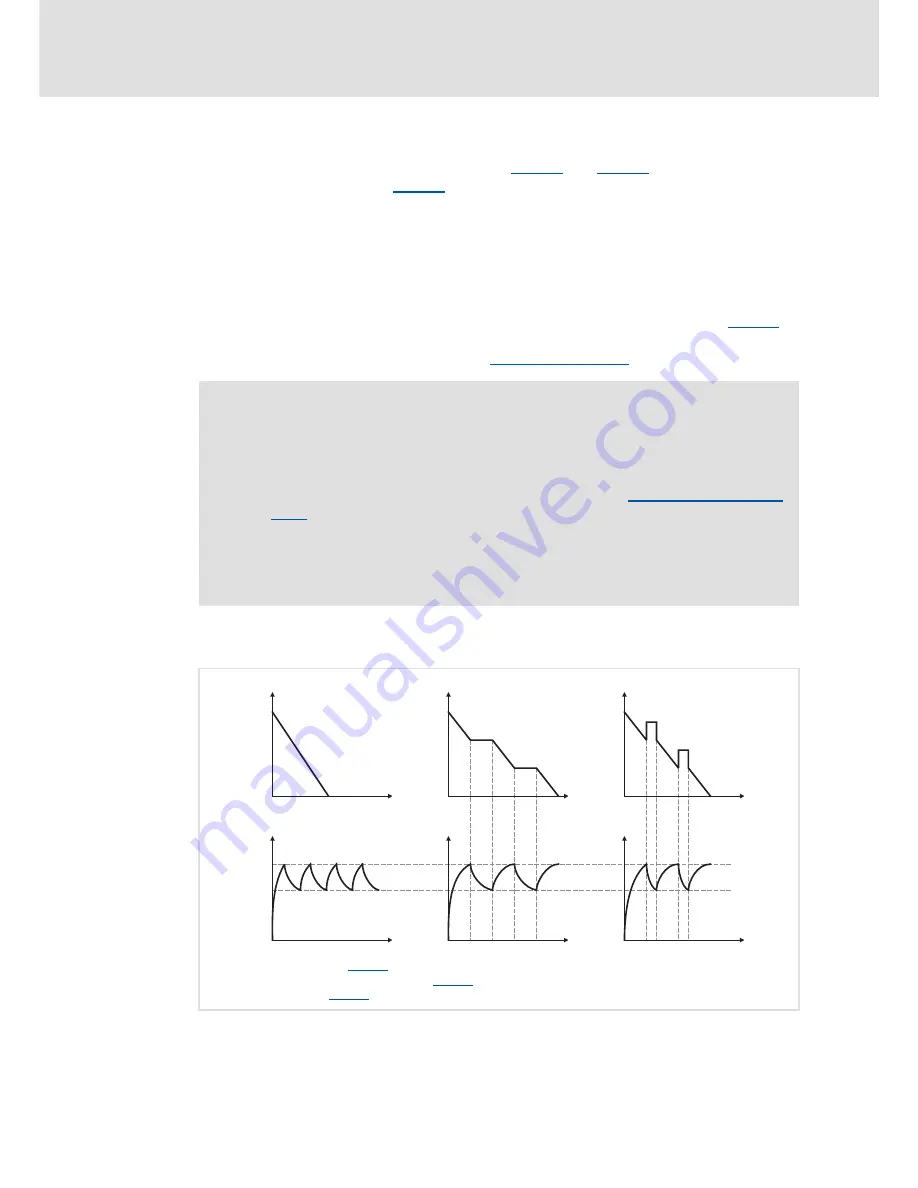

The way in which the different braking procedures work is demonstrated schematically in

the following illustration:

[5-26] Graph of the effective speed setpoint and the DC bus voltage during braking

Stop!

• The two braking procedures "Stopping of the ramp function generator" and

"Inverter motor brake" can only be used for speed-controlled applications

without the influence of a position controller!

• When the "inverter motor brake" function is used, the

Motor load monitoring

(I2xt)

is not adapted. If it is braked too frequently, there is a risk of the motor

being thermally overloaded or the motor overload monitoring does not work

properly!

• The "inverter motor brake" function must not be used with vertical conveyors

(hoists) or with active loads!

Use of the brake resistor (

C00175

= "0: Brake resistor")

Stopping of the ramp function generator (

C00175

= "1: HlgStop")

Inverter motor brake (

C00175

= "3: FI_ RfgStop)

n

Set

t

n

Set

t

1

2

n

Set

t

0

t

t

t

U

DC

U

DC

U

DC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com