S94P01C -e1

15

EMC

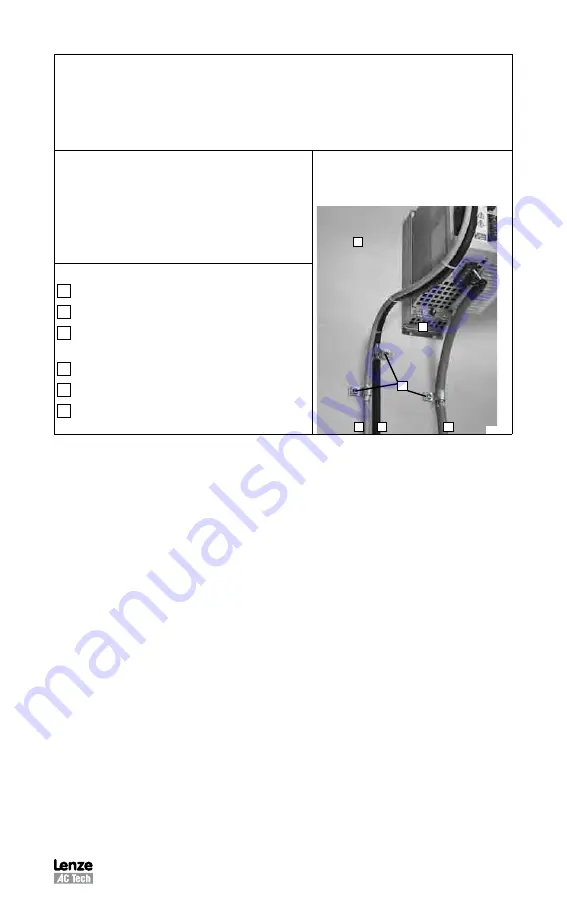

Compliance with EN 61800-3:2004

In a domestic environment this product may cause radio interference in which the

user may be required to take adequate measures

Noise emission

Drive Models ending in the suffix “2F” are in

compliance with class A limits according to

EN 55011 if installed in a control cabinet and

the motor cable length does not exceed 10m.

Models ending in “N” will require an appropriate

line filter.

Installation according to EMC

Requirements

E

D

B

C

A

F

S930

A Screen clamps

B Control cable

C Low-capacitance motor cable

(core/core < 75 pF/m, core/screen < 150 pF/m)

D Earth grounded conductive mounting plate

E Encoder Feedback Cable

F Footprint or Sidemount Filter (optional)

4.2.2 EMI Protection

Electromagnetic interference (EMI) is an important concern for users of digital

servo control systems. EMI will cause control systems to behave in unexpected and

sometimes dangerous ways. Therefore, reducing EMI is of primary concern not only

for servo control manufacturers such as Lenze, but the user as well. Proper shielding,

grounding and installation practices are critical to EMI reduction.

4.2.3 Enclosure

The panel in which the PositionServo is mounted must be made of metal, and must be

grounded using the SPG method outlined in section 4.2.1.

Proper wire routing inside the panel is critical; power and logic leads must be routed in

different avenues inside the panel.

You must ensure that the panel contains sufficient clearance around the drive. Refer

to Section 3.2 suggested cooling air clearance.