Configuration

8-11

BA9300SU EN 2.1

5. The entries in C0465 are:

– Position 10: AND1 10500

– Position 11: OR1 10550

– Position 12: AND2 10505

This example was started with position 10, because these positions are not assigned in the default

setting.

FBs need not to be entered into the processing table one after the other. Empty positions in the

processing table are permissible.

Tip!

It is also possible that other FBs are entered between the FBs listed in the example.

FBs which do not have to be entered into the processing table

The following signal sources are always executed and do not have to be entered into the processing

table:

•

AIF-IN

•

CANx-IN

•

DIGIN

•

DIGOUT

•

FCODE (all free codes)

•

MCTRL

•

fixed signal sources (FIXED0, FIXED0% , etc.)

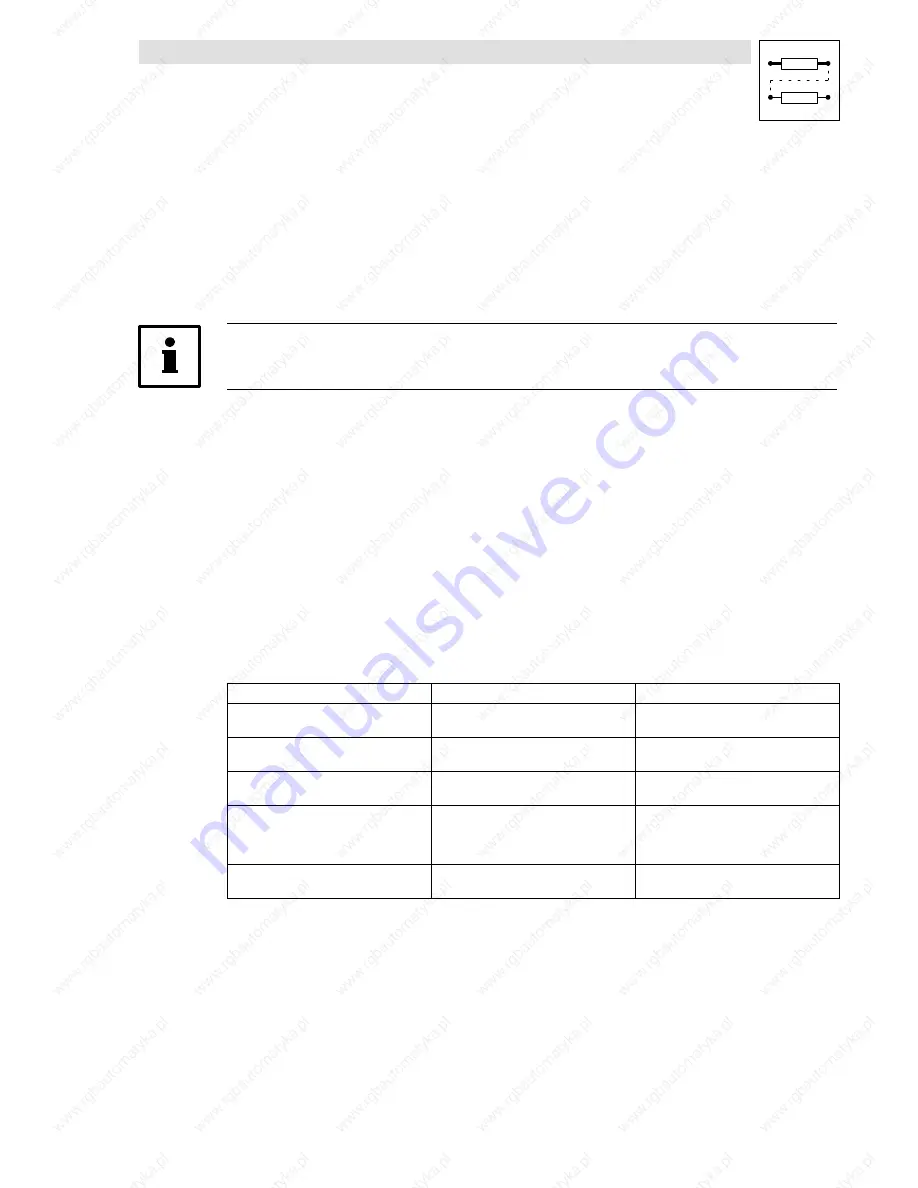

Frequent faults in the configuration

Malfunction

Cause

Remedy

FB does not supply an output signal

FB was not entered into the processing table

C0465

Enter FB

FB only supplies constant signals

FB was deleted from or overwritten in the

procesing table C0465.

Enter FB again, possibly under a different

subcode (position)

The output signal does not arrive at the

following FB.

No connection between the FBs

Make connection (from the view of the next

FBs) by the configuration code (CFG)

FB cannot be entered in the table C0465

Residual process time is too short (see

C0466)

Remove FBs not used (e.g. inputs and outputs

not used)

In networked drives, functions may be

relocated to other controllers

The controller outputs internally calculated

signals with a delay

FBs are processed in an incorrect sequence

Adapt processing table under C0465 to the

signal flow

Summary of Contents for EVS9321-CS

Page 3: ...Operating Instructions EDB9300UES 00414796 Global Drive 9300 servo ...

Page 21: ...Technical data 3 8 BA9300SU EN 2 1 ...

Page 57: ...Installation 4 36 BA9300SU EN 2 1 ...

Page 73: ...During operation 6 4 BA9300SU EN 2 1 ...

Page 117: ...Troubleshooting and fault elimination 9 10 BA9300SU EN 2 1 ...

Page 119: ...Maintenance 10 2 BA9300SU EN 2 1 ...

Page 188: ...Appendix 11 69 BA9300SU EN 2 1 ...

Page 189: ...Appendix 11 70 BA9300SU EN 2 1 ...