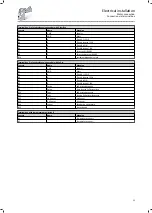

Maintenance intervals

Geared motor/gearbox

Time interval

Measures

Description of the operations

After assembly and after 3 hours , check fastening.

Check all fixing screws on the gearbox (foot, flange and shrink disc fixing ...)

for tightness.

On the first day, then every

month

General check

Pay attention to unusual operating noises, vibrations and impermissibly high

temperatures

Check tightness

In case of leakage, eliminate cause of leakage and check lubricant level.

Every 6 months

Clean geared motor/gearbox

Remove dirt and dust deposits. Clean more frequently in the case of heavy

dirt accumulation

Check rubber buffer

Check rubber buffer of the torque plate and replace it in the event of visible

wear or damage

Relubricate roller bearings

For gearboxes with adapter and grease nipple:

Relubricate the roller bearings in the adapter using a grease gun.

Grease: Klüber Microlube GLY 92, amount approx. 5 grams

Annually

Check vent valve

Check whether air can pass through the breather element. If it shows

blockages, replace it

According to diagram; at the

latest as specified in the lubricant

table

Change lubricant

Change lubricant

For type and amount of lubricant see nameplate

Replace roller bearing grease

filling

Rolling bearing greases should also be renewed when changing the lubricant

The following gearboxes are lubricated for life:

•

G50BS113

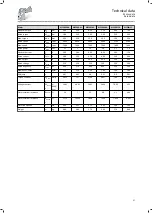

Lubricants

For gearboxes not lubricated for life, change the lubricant at regular intervals.

The type of lubricant is indicated on the nameplate. Only use the same type of lubricant.

The change interval depends on the lubricant temperature during operation.

The replacement intervals listed in the lubricant table are reference values for normal ambient

conditions. Shorter periods are required for more difficult operating conditions (e.g.

aggressive ambient media).

At higher oil temperatures, determine the change interval from the following lubricant

diagram.

Maintenance

Maintenance intervals

44