Mechanical installation

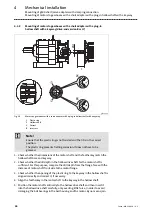

Mounting of g500 short/servo adapters with clamping connection

Coupling hubs

33

Lenze ¯ MA 12.0018 ¯ 4.1

4.3.8

Coupling hubs

General

Note!

Standard hubs, clamping hubs and clamping ring hubs are

maintenance−free.

We recommend carrying out a visual inspection of the star−shaped

spider/ring gear and the system parts within the inspection intervals.

Note!

Tighten all screws to the coupling hubs and the motor fastening of

gearboxes in ATEX design with an intermediate strength screw retention.

Mounting the standard hub / clamping hub

1. Fit motor keyway (2).

–

With some sizes a shorter featherkey is supplied, which is to be mounted. The

sizes concerned by this are shown on (

2. With a clamping hub:

–

slightly loosen the clamping screw

–

Fit coupling hub on the motor shaft using a center hole thread (do not mount by

hammer strokes, in order to avoid damage to the roller bearings in the motor).

–

Observe mounting dimension m of the coupling hub (

3. Secure coupling hub against axial movement using the fixing screw or clamping

screw (1).

4. Lay spider in the coupling claw on the gearbox side.

–

The mounting process can be facilitated by lightly greasing or oiling the ring

gear sides or the hub sides. For this purpose, only use mineral oil−based

lubricants without additives, silicone−based lubricants, or vaseline.

5. Align claws of the motor−side coupling hub with its counterpart.

6. Slowly push on motor, and bolt on to the gearbox flange.