Mechanical installation

Important notes

•

You must install the product according to specifications in the chapter "standard and operating" condi-

tions.

Standards and operating conditions

•

The technical data and the data regarding the supply conditions can be found on the nameplate and in

this documentation.

•

Observe the information relating to the surface and corrosion protection.

•

Ambient media − especially chemically aggressive ones − may damage shaft sealing rings, lacquers and

plastics. If required, contact your responsible Lenze subsidiary.

Transport

•

Ensure appropriate handling.

•

Make sure that all component parts are safely mounted. Secure or remove loose component parts.

•

Only use safely fixed transport aids (e.g. eye bolts or support plates).

•

Do not damage any components during the transport.

•

Avoid electrostatic discharge on electronic components and contacts.

•

Avoid impacts.

•

Check the carrying capacity of the hoists and load handling devices. The weights can be obtained from the

shipping documents.

•

Secure the load against tipping and falling down.

•

Standing under a suspended load is forbidden.

Preparation

•

Remove protection covers from the shafts

•

Remove corrosion protection from the shafts and contact surfaces (flange/foot)

•

If necessary, remove dirt using standard cleaning solvents

NOTICE

Material damage caused by solvents!

Solvents can destroy bearings and sealing rings.

▶

Bearings or sealing rings must not come into contact with the solvent!

Installation

•

Avoid resonances with the rotational frequency and double mains frequency.

•

The mounting surfaces must be plane, torsionally rigid and free from vibrations.

•

The mounting areas must be suited to absorb the forces and torques generated during operation.

•

Ensure an unhindered ventilation.

•

For versions with a fan, keep a minimum distance of 10 % from the outside diameter of the fan cover in

intake direction.

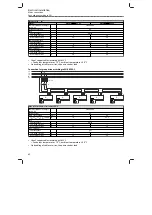

Dimensions

Dimensions are contained in the configuration document.

Mechanical installation

Important notes

54