10

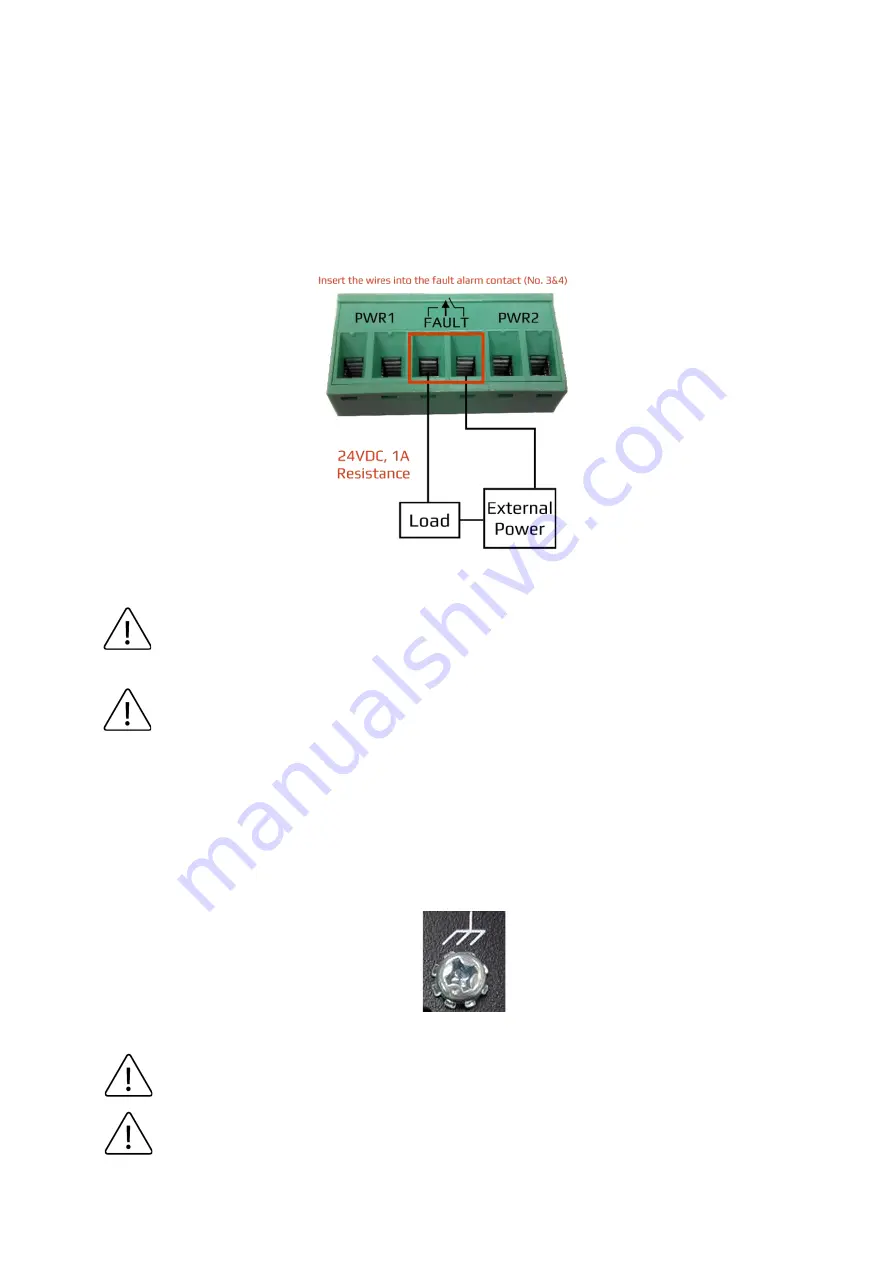

Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of the terminal block connector as the picture shows

below in Figure 2.11. By inserting the wires, it will detect the fault status including power failure

or port link failure (managed industrial switch only) and form a normally open circuit. An

application example for the fault alarm contact is shown below in Figure 2.11.

Figure 2.11: Wiring the Fault Alarm Contact

Caution:

The wire gauge for the terminal block should range between 12 ~ 24 AWG.

If only using one power source, jumper Pin 1 to Pin 5 and Pin 2 to Pin 6 to eliminate

power fault alarm.

Attention:

Le calibre des fils du bornier doit être compris entre 12 et 24 AWG.

Si vous n'utilisez qu'une seule source d'alimentation, jumelez les broches 1 à 5 et les

broches 2 à 6 pour éliminer l'alarme de panne de courant.

Grounding Note

Grounding and wire routing help limit the effects of noise due to electromagnetic interference

(EMI). Run the ground connection from the ground screw to the grounding surface prior to

connecting devices. The grounding screw symbol is shown blow in Figure 2.12.

Figure 2.12: Grounding screw symbol

Caution:

Using a shielded cable achieves better electromagnetic compatibility.

Attention:

L'utilisation d'un câble blindé permet une meilleure compatibilité

électromagnétique.