9

Wiring the Power Inputs

Caution:

Please follow the below steps to insert the power wire.

Attention:

Veuillez suivre les étapes ci-dessous pour insérer le câble d'alimentation.

Step 1

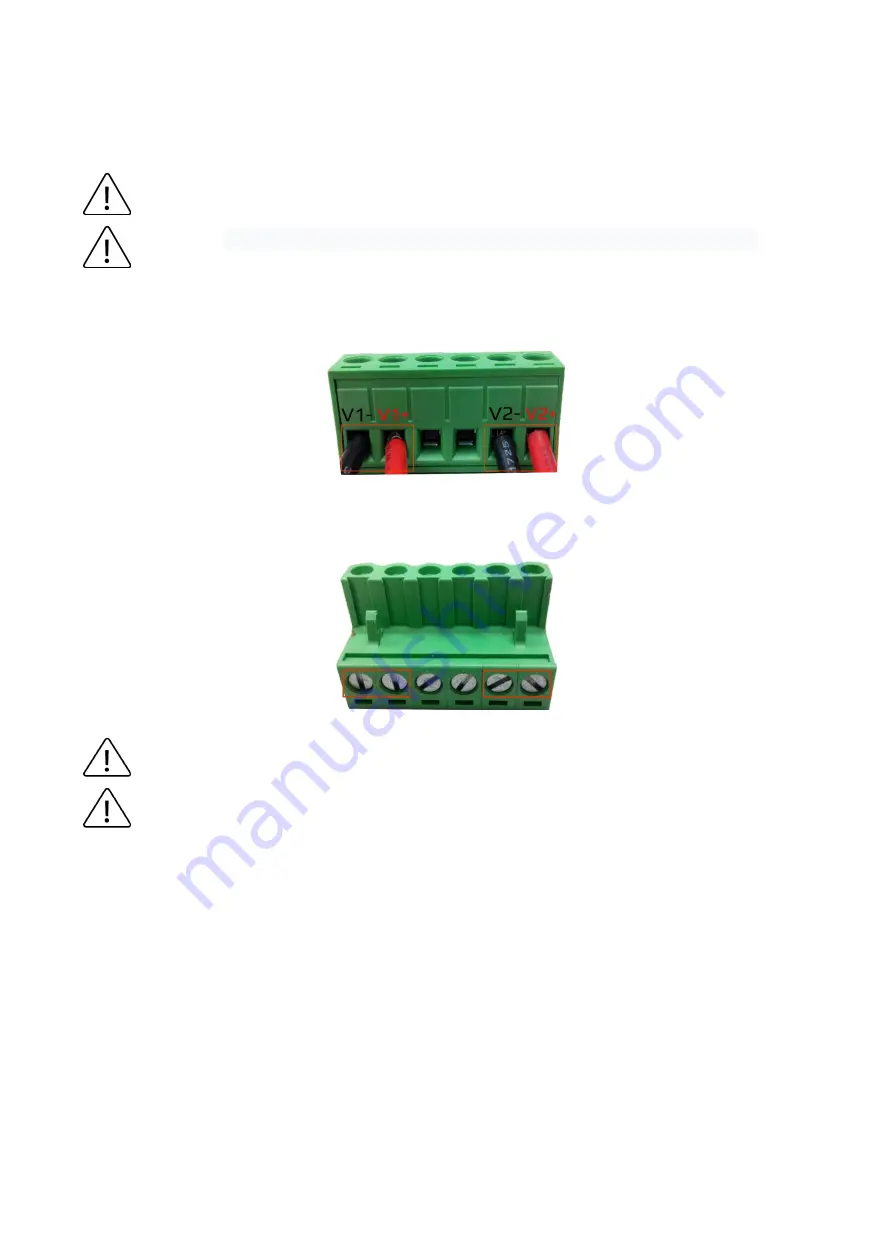

Insert the positive and negative wires into the PWR1 (V1+, V1-) and PWR2 (V2+, V2-)

contacts on the terminal block connector as shown below in Figure 2.9.

Figure 2.9: Power Terminal Block

Step 2

Tighten the wire-clamp screws to prevent the wires from loosening, as shown below in

Figure 2.10.

Figure 2.10: Power Terminal Block

Caution:

Only use copper conductors, 125°C, tighten to 5 in-lbs (0.56 Nm). The wire gauge

for the terminal block should range between 18~20 AWG.

Attention:

Utilisez uniquement des conducteurs en cuivre, 125°C, serrez à 5 in-lbs (0.56

Nm). Le calibre du bornier doit être compris entre 18 et 20 AWG.

Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of the terminal block connector as the picture shows

below in Figure 2.11. By inserting the wires, it will detect the fault status including power

failure or port link failure (managed industrial switch only) and form a normally open circuit.

An application example for the fault alarm contact is shown below in Figure 2.11.