28 / 31

7. If correct operation cannot be achieved, repeat the adjustment process from step 1.

7.3 Replacement of the manual release lever:

1. Extract the lever to be replaced by turning it so that is goes away from the opposite lever.

Fig. 38

Remember that the threading of each lever is in the opposite direction.

2. For assembly of a new lever follow the procedure explained in section 3.7 of the manual.

29 / 31

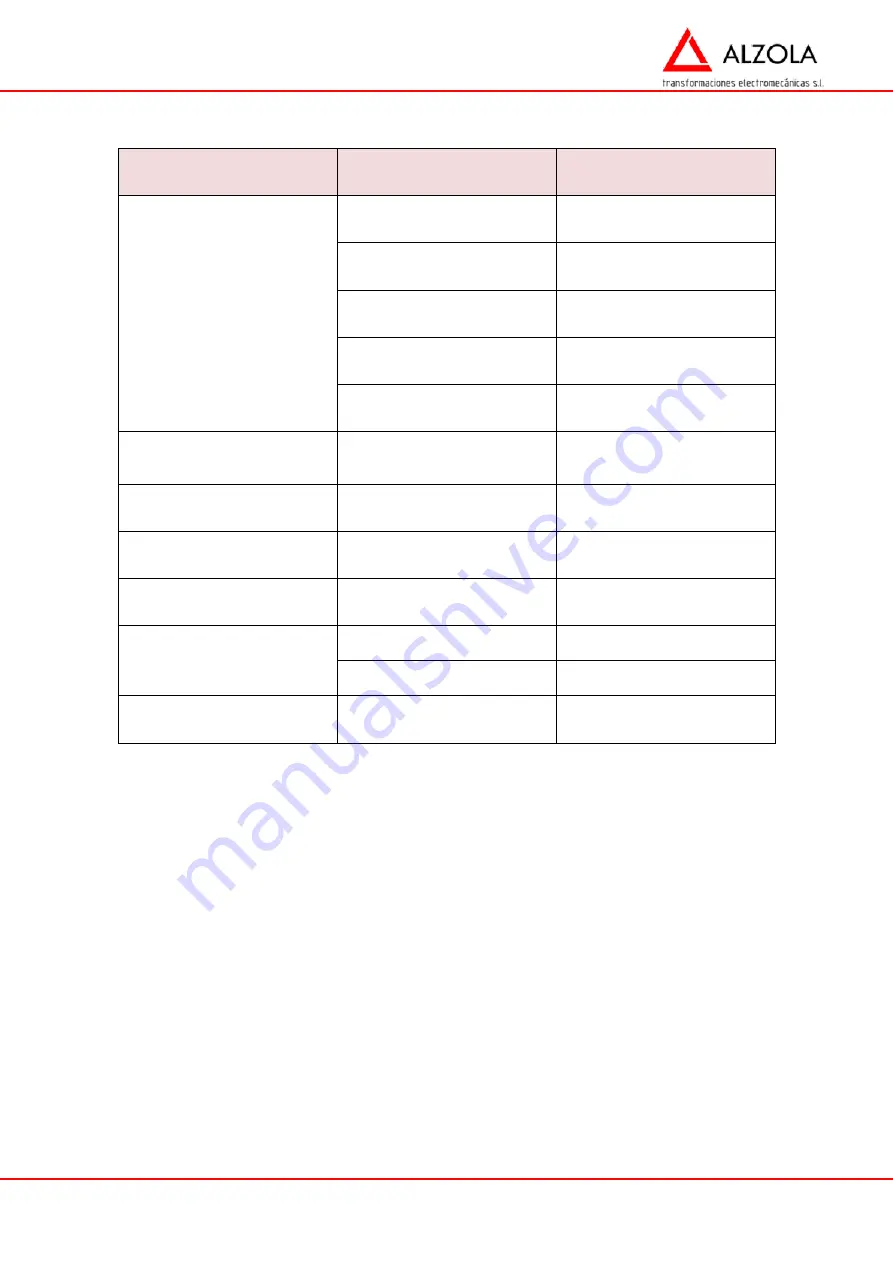

8 POTENTIAL FAILURES:

Failure

Possible reasons

Solutions

The brake does not work.

Wrong Voltage.

Apply the correct voltage.

Air-gap

too large (disc

deteriorated).

Replace the rotor.

Coil broken.

Replace the brake.

Micro-switch

broken.

Change the

micro-switch

.

Micro-switch

badly adjusted.

Adjust the micro

-switch

.

The brake is slow to react in

the case of an emergency

stop.

The brake is connected to an

alternating current.

Connect to the direct current.

The brake does not release.

Particles stop the casing from

moving.

Replace brake.

The torque is insufficient.

Greasy disc.

Clean disc support and replace

the disc.

The brake is very noisy.

Air-gap

too large.

Replace disc.

The brake gets too hot.

Wrong Voltage.

Apply the correct voltage.

The winding is short-circuited. Replace the brake.

The release lever turns.

Tightening torque is

insufficient.

Tighten (See table 3.1).

Table 7

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......