Maintenance and repair

INTORQ | BA 14.0197 | 06/2014

41

7.3

Maintenance

7.3.1

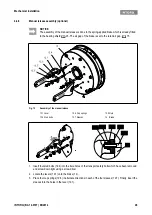

Check the rotor thickness

1. Stop motor and control system!

2. Remove the motor cover and remove the cover ring, if present.

3. Measure the rotor thickness using a caliper gage.

4. Compare the measured rotor thickness against the minimal permitted rotor thickness (

15).

5. If required, replace the rotor completely. Description, see

42.

7.3.2

Check the air gap

1. Stop motor and control system!

2. Measure the air gap "s

L

" near the fixing screws between the armature plate and the stator using a feeler

gauge.

3. Compare the measured air gap with the maximum permitted air gap "s

Lmax

" (

15).

4. If required, replace the rotor completely. Description, see

42.

NOTICE

Brakes with defective armature plates, socket head cap screws, springs or counter friction

faces must always be replaced completely.

Generally observe the following for inspections and maintenance works:

❚

Contamination by oils and greases should be removed using brake cleaner, or the brake

should be replaced after determining the cause. Dirt and particles in the air gap between

the stator and the armature plate endanger the function and should be removed.

❚

After replacing the rotor, the original braking torque will not be reached until the run-in op-

eration for the friction surfaces has been completed. After replacing the rotor, the run-in ar-

mature plates and counter friction faces have an increased initial rate of wear.

DANGER

Danger: rotating parts!

The motor must not run during the check.

DANGER

Danger: rotating parts!

The motor must not run during the check.

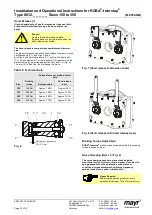

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......