9

INSTALLATION

E27 Gearless - Installation and maintenance

5323 en - 2018.04 / c

The direction of the force applied onto the traction sheave

must be vertical and must be perpendicular to the motor feet.

the force applied must compress the isolation pads.

5.3.4 - Ropes guard

When the ropes have been installed, fit the ropes guard system.

Ropes guard system

: 2 blades

2 screws HM8 x 16

2 washers 8-22/2

Installation

:

- Use one of the 3 appropriate holes on the blade, depending

on ropes wrapping angle on the sheave (centered one in the

most of case).

- Screw one blade on each side of the sheave, using the 2

threated holes on motor housing.

- Use Loctite 242 (or equivalent) on the tap of each bolt

- Adjust the distance between blade and sheave:

distance < 0.8 rope diameter.

- Tighten at a torque of 15 N.m +/- 10%.

There is a high risk of jamming your fingers

between the cables and the sheave.

5.3.5 - Optional

Protection device for sheave and/or brake.

E27 motor is available with 2 additional options:

- Protection device for sheave

- Protection device for brake

Sheave protection

Brake protection

Installation

:

When the ropes have been installed, fit the protection device

for sheave or for brake.

Sheave or brake protection device

: 1 cover blade

2 screws HM8 x 16

2 washers 8-22/2

- Screw the cover blade, using the 2 threated holes on brake

support.

- Use Loctite 242 (or equivalent) on the tap of each bolt

- Tighten at a torque of 15 N.m +/- 10%.

There is a high risk of jamming your fingers

between the cables and the sheave.

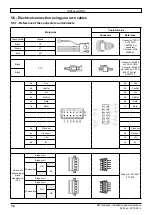

5.4 - Electrical connection using the

cables supplied by Leroy-Somer

5.4.1 - Wiring the motor, the thermal sensor

and the encoder

Remove the cover using a Torx screwdriver or key, reference

TX 30.

When working on the encoder please follow the below

recommendation:

NO

NO

NO

YES

Summary of Contents for E27 Series

Page 4: ...4 E27 Gearless Installation and maintenance 5323 en 2018 04 c...

Page 15: ......

Page 46: ...30 31 NOTES...

Page 109: ......

Page 110: ......

Page 111: ......