8

LESCO

MAINTENANCE

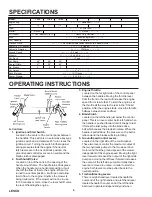

Figure 1

E. ENGINE MAINTENANCE: For detailed maintenance

instructions for the engine on your mower, see the

Engine Manual packed with your mower.

F. HYDRAULIC SYSTEM MAINTENANCE: The

hydraulic system should not require maintenance

other than the changing of the hydraulic oil and the

oil filter at 100 hours and every 500 hours

thereafter. The pumps and wheel drive motors are

WARNING

Disconnect the spark plug wire to prevent

the engine from accidentally starting before

performing any maintenance on this mower.

A. GENERAL MAINTENANCE:

1. If the mower must be tipped on its side for

maintenance, first drain the fuel from the fuel tank,

the oil from the engine’s crankcase and the hydrau-

lic oil from the supply tank.

2. Be careful not to spill oil on any of the belts.

3. Do not tamper with the engine’s governor settings.

They are adjusted to provide the proper maximum

engine speed.

4. If the mower is to be in storage for more than 30 days, drain

the fuel tank, run the engine to drain the carburetor dry,

change the oil, remove the spark plug and pour a teaspoonful

of oil into the cylinder. Run the starter briefly to crank the

engine and distribute the oil then replace the spark plug.

B. DAILY MAINTENANCE AFTER MOWING:

1. Park the mower outside the storage facility with the

engine shut off.

2. Close the fuel shutoff valve.

3. Permit the mower to cool.

4. Disconnect the spark plug wire.

5. Wash the mower off with a water hose. Be sure to

clean out grass clippings from under the cutter

deck and also under the deck cover. Allow the

mower to dry before storing.

6. Check that the blade mounting bolts are tight.

7. Check that the blades are sharp. NOTE: Never

mow with dull blades.

8. Check the fuel level, the engine oil level and clean

the cooling-air intake (the rotating screen).

9. Clean the air cleaner elements (foam and paper).

10. After the first 5 hours of use, change the engine oil.

(Change the oil every 40 hours thereafter.)

11. Follow the lubrication chart at the top of the page.

12. Place the mower in locked storage to avoid tamper-

ing or use by an untrained operator.

13. Check condition and operation of all safety switches

C. MAINTENANCE EVERY 100 HOURS:

1. Change the engine oil and replace the oil filter.

(Change the engine oil more frequently under

severe operating conditions.)

2. Change the hydraulic oil and the oil filter after the

first 100 hours and every 500 hours thereafter.

2. Check that all nuts, bolts and screws are tight.

3. Check the condition and tension of all belts.

4. Clean the spark plug and check the spark plug gap.

5. Follow the lubrication chart at the top of the page.

D. LUBRICATION CHART

NUMBER OF GREASING POSITIONS

(See Figure 1 and 1a below for Item Locations.)

48" Item

Description

DAILY LUBRICATION CHART

3

A

Cutter Blade Spindle Bearings

40 HOUR LUBRICATION CHART

2

B

Caster Wheel Bearing

2

C

Caster Wheel Pivot Shafts

2

D

Deck ldler Pulley Pivot Arms

1

Blade Clutch Bellcrank Pivot

Figure 1a