25

Vacuum motor fuse blown

Replace the fuse

Vacuum motor or wiring failure Please contact the service center

Motor carbon brush wear

Please contact the service center

Small or no water flow

Clean water tank filter or

solution tube blocked

Clean water tank filter

Flow control knob flow rate

setting is too low

Adjust water flow control knob

Loosen the knob of the control

knob

Lubricate the knob and tighten

the screw

Low efficiency in recycling

waste water

The sewage tank is full

Drain the sewage tank

Absorbent rubber strip wear

Replace water absorbent strip

The suction pipe is blocked

Remove the clogged debris

Damage to the sewage tank seal

Replace the seal

Vacuum motor failure

Please contact the service center

Shortened running time

The battery is defective

Replace the battery

Battery charging failure

Repair or replace the charger

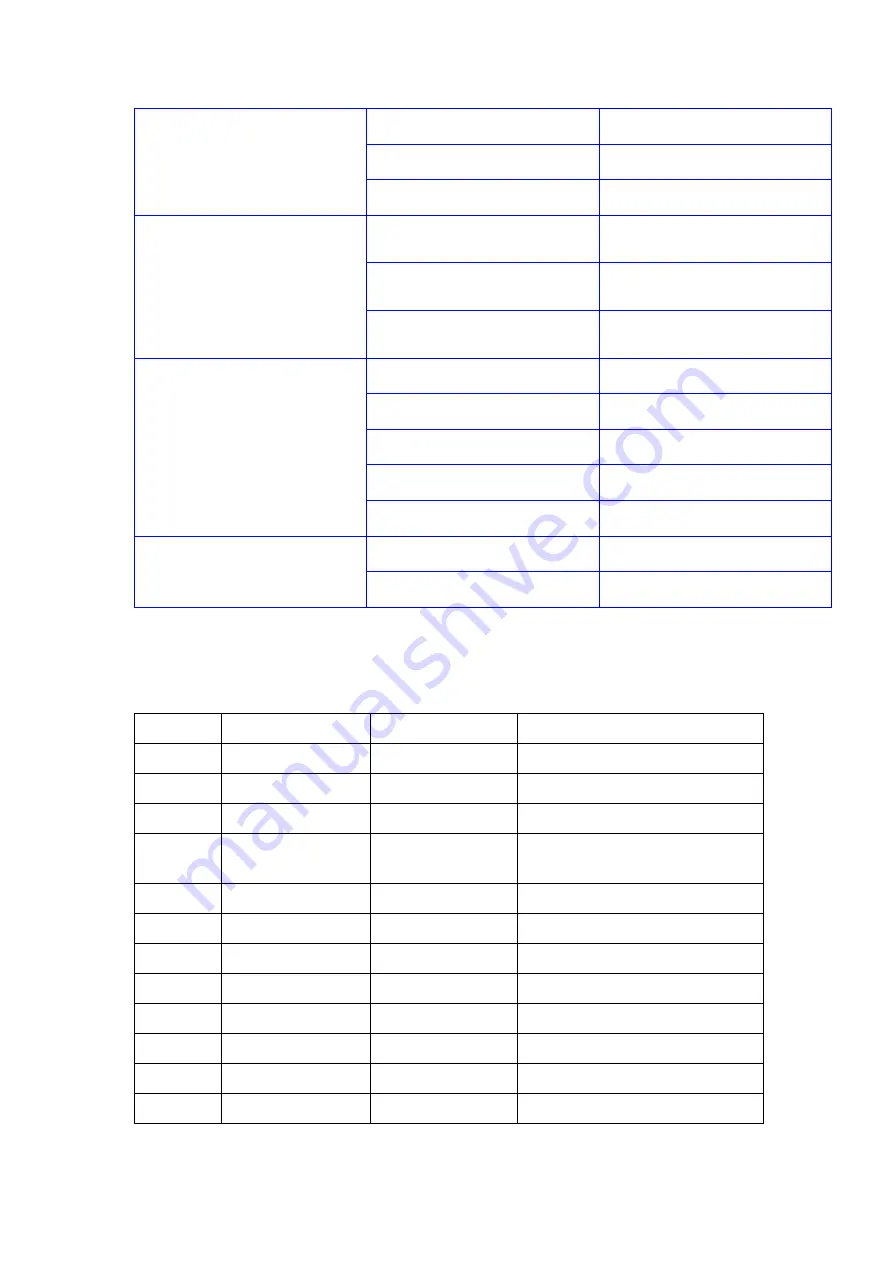

Technical Parameters

NO.

Item Name

Unit

SJ860

1

Cleaning width

mm

850

2

Cleaning efficiency

m2/h

6000

3

Squeegee width

mm

1200

4

Continuous operation

time

H

6-8

5

Climb

°

<

25°

6

Water tank

L

150

7

Sewage tank

L

165

8

Brush motor

W

500*2

9

Noise level

dBA

60

10

Battery

V

24

11

Machine size

mm

1600*1100*1450

12

Machine weight

kg

445KG

Summary of Contents for SJ860

Page 1: ...1 SJ860 Driving floor scrubber User s manual ...

Page 7: ...7 ...