Electrical connection

7

8

BCL

3

00

i

\ BCL

3

01

i

Le

u

ze electronic

7.2

Electrical connection BCL 300

i

For the electric

a

l connection of the BCL

3

00

i

, 4 connection v

a

ri

a

nt

s

a

re

a

v

a

il

ab

le.

The

volta

g

e

s

upply

(1

8

…

3

0VDC) i

s

connected

a

cc. to the connection type

s

elected.

2 freely pro

g

rammable

s

witchin

g

input

s

/output

s

for individ

ua

l

a

d

a

pt

a

tion to the re

s

pec-

tive

a

pplic

a

tion

a

re

a

l

s

o

a

v

a

il

ab

le here. Det

a

iled inform

a

tion on thi

s

topic c

a

n

b

e fo

u

nd in

ch

a

pter 7.4.1

a

nd ch

a

pter 7.4.

3

.

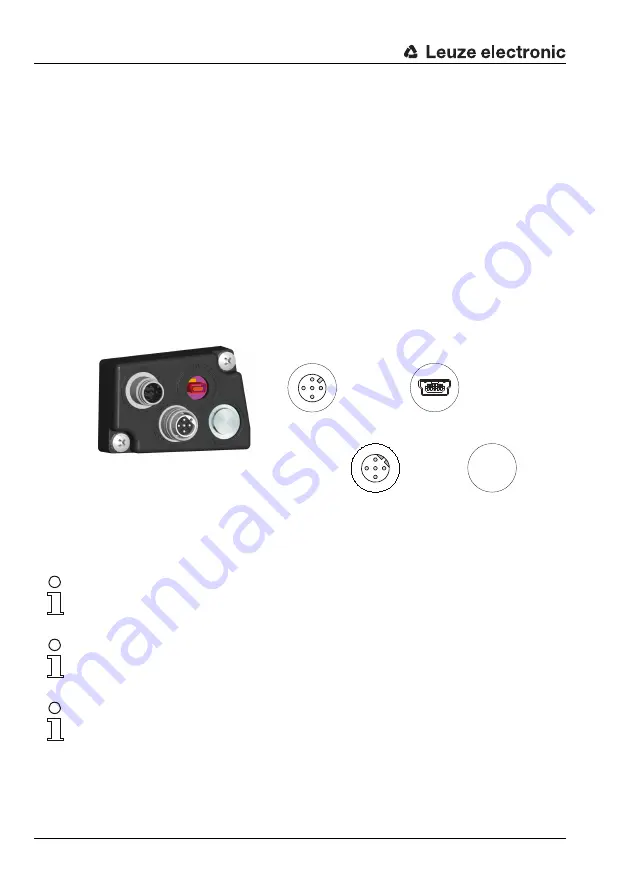

7.2.1

M

S

300 hood with 2 inte

g

rated M12 connector

s

The M

S 3

00 hood with integr

a

ted connector

s

fe

a

t

u

re

s

two M12 connector pl

u

g

s

a

nd

a

Mini-B type U

S

B

s

ocket

as

a

s

ervice interf

a

ce. P

a

r

a

meter memory i

s

integr

a

ted into the

M

S 3

00 which tempor

a

rily

s

tore

s

the

s

etting

s

of the BCL

3

00

i

in the c

as

e of repl

a

cement

a

nd tr

a

n

s

mit

s

them to

a

new device.

Fig

u

re 7.2:

BCL

3

00

i

- M

S 3

00 hood with integr

a

ted M12 connector

s

Notice!

The shielding connection is done via the M12 connector housing.

Notice!

The integrated parameter memory for the simple replacement of the BCL 300

i

is located in

the MS 300.

Notice!

See chapter 5.3.6 "Dimensioned drawing of MS 3xx hood with integrated connectors /

MK 3xx terminal hood" dimensioned drawing on page 51.

HOST / BUS IN

GND_ISO 3

2

1

4

RXD/RX-

TXD/TX-

RTS/TX+

CTS/RX+

5

PWR / SW IN/OUT

SWIO_2

SWIO_1

3

2

1

4

5

GNDIN

VIN

FE

SERVICE

2

1 3 5

4

GND

D+

D-

VB

ID

BUS OUT

Mini-B U

S

B

s

ocket

(

b

ehind protective c

a

p)

M12 pl

u

g

(A-coded)

M12 pl

u

g

(B-coded)

D

u

mmy pl

u

g

Hood with integr

a

ted connector

s

M

S 3

00