Configuration / device parameters

Leuze electronic

BPS 8

74

TNT

35/7-2

4

V

Maximum position value which can be represented

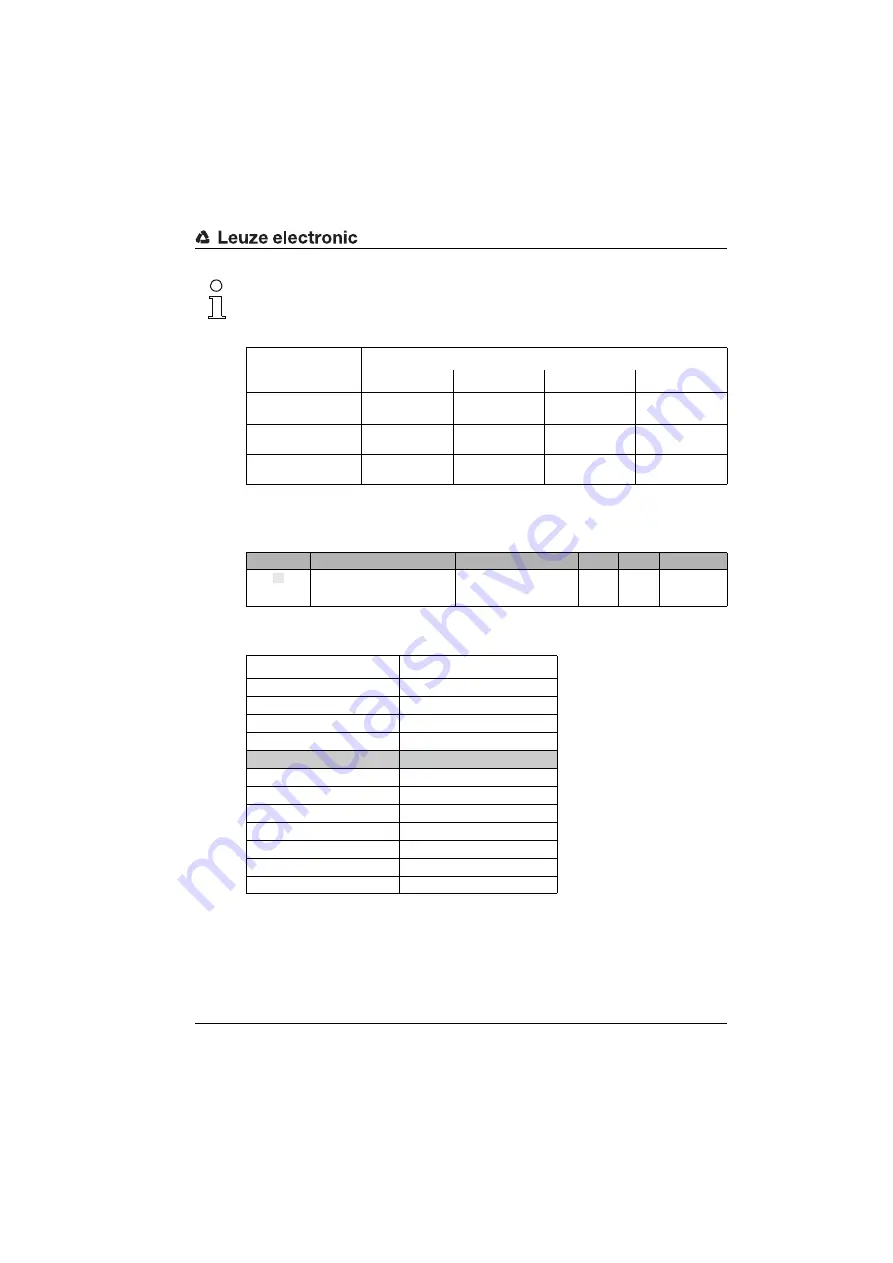

The binary protocols 1 to 6 convey the position value with a different number of data bits.

The number of data bits and the selected resolution determine the maximum position value

that can be represented.

Integration depth parameter

The integration depth parameter is used to specify the number of raw position data which is

used for integration in order to determine the position value.

In order to obtain more exact measurement data while in the static state or for very slow

travel speeds, the integration depth can be increased here. If, however, a high integration

depth is used for high speeds, the contouring error is increased. With respect to contouring

errors and exact measurement data, very good results have been obtained using 8 integra-

tion steps. Using 8 integration steps, the integration time is 26.4ms.

Maximum position value which can be represented with a resolution of

1mm (default)

0.1mm

0.01mm

0.001mm

Binary protocol 1, 4, 6

(32 data bits)

10,000,000

mm

1)

1)

The maximum position value that can be presented is limited by the maximum length of

the bar code tape.

10,000,000mm

1)

10,000,000mm

1)

4,294,967mm

Binary protocol 2

(24 data bits)

10,000,000mm

1)

1,677,721mm

167,772mm

16,777mm

Binary protocol 3

(21 data bits)

2,097,152mm

209,715mm

20,971mm

2,097mm

Parameter

Description

Value range

Default

Unit

CR

Integration

time

Number of consecutive scans

which are to be used for position

determination.

4 … 32

8

Integra-

tion

steps

–

Integration depth

Integration time [ms]

4

13.2

5

16.5

6

19.8

7

23.1

8 (default)

26.4

9

29.7

10

33.0

:

:

29

95.7

30

99.0

31

102.3

32

105.6

b