17

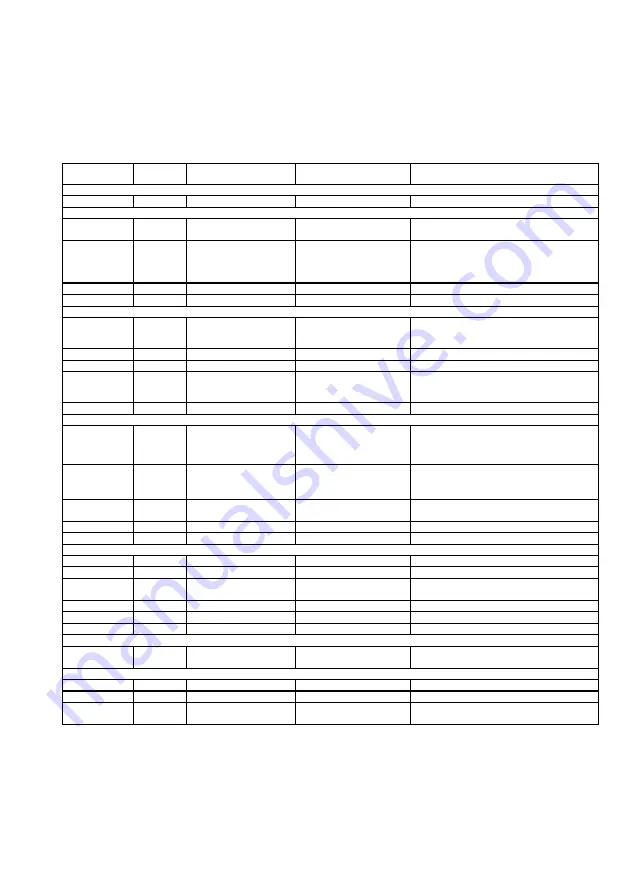

Checklist for periodic checks (normally yearly

– more frequently if necessary)

Daily

Yearly

Inspection items

Inspection method

Note

Labels

X

X

Rating plate

Visual

If the plate is hard to read - replace it

Function

X

X

Raising and lowering

function

Test without load

A low snapping noise should be audible

–

X

Raising and lowering

function

Try with 125% of rated

load over a distance of

min. 300 mm.

The lever runs easily. Load chain sprocket

and chain work well together Brake works.

The chain does not twist or tangle Hand

pulling on the lever feels even

X

X

Selector

Operation

Easy to reset

X

X

Neutral

Operation

Function

Hooks

X

–

X

Hook opening

Visual

Measurement

Looks normal

See Fig. 5 and Table 2

X

Deformation

Visual

No visible deformation

X

X

Hook bearing

Visual

No abnormal play

X

–

X

Wear, cracks, defor-

mation and corrosion

Visual

Measurement

No visible damage

See Fig. 5 and Table 2

X

X

Hook latches

Visual

Works, spring entire

Chain

X

–

X

Pitch

Visual

Measurement

Looks normal.

Measure in case of doubt

See Fig. 7 and Table 3

X

–

X

Wear

Visual

Measurement

Looks problem-free. Measure in case of

doubt

See Fig. 7 and Table 3

X

X

Deformation

Visual

No deformation. Measure in

case of doubt.

X

X

Cracks etc.

Visual

No cracks

X

X

Rust

Visual

No rust

Housing

X

X

Housing

Visual

No deformation and no rust

–

X

Operating lever

Visual

No deformation

–

X

Load chain sprocket

Visual after dismantling

No serious wear or cracks. No fractures or

deformation

–

X

Bearings

Visual, testing

No damage, smooth running

–

X

Gears

Visual after dismantling

No serious wear or fractures

X

X

Chain stop

Visual

Must be free of deformation

Screws

X

X

Screws, nuts, rivets,

cotters etc.

Visual

Must not be missing. Tighten loose items.

Replace as necessary

Brake

–

X

Brake disk

Visual

Replace if worn

–

X

Brake screw

Visual

No serious wear

–

X

Pawl and ratchet.

Visual

Replace worn parts..

Carefully lubricate with grease.