LIMITED 5 YEAR WARRANTY AND EXCLUSIONS

Leviton warrants to the original consumer purchaser and not for the benefit of anyone else that this product at the time of its sale by Leviton is free of defects in materials and workmanship under normal and proper use for five years from the purchase date. Leviton’s only obligation is to correct such defects by repair or replacement, at its option, if within such five year period the product is returned prepaid, with proof of purchase

date, and a description of the problem to

Leviton Manufacturing Co., Inc., Att: Quality Assurance Department, 59-25 Little Neck parkway, Little Neck, New York 11362-2591.

This warranty excludes and there is disclaimed liability for labor for removal of this product or reinstallation. This warranty is void if this product is installed improperly or in an improper environment, overloaded, misused, opened, abused, or altered in

any manner, or is not used under normal operating conditions or not in accordance with any labels or instructions.

There are no other or implied warranties of any kind, including merchantability and fitness for a particular purpose

, but if any implied warranty is required by the applicable jurisdiction, the duration of any such implied warranty, including merchantability and fitness for a particular purpose, is limited to five

years.

Leviton is not liable for incidental, indirect, special, or consequential damages, including without limitation, damage to, or loss of use of, any equipment, lost sales or profits or delay or failure to perform this warranty obligation

. The remedies provided herein are the exclusive remedies under this warranty, whether based on contract, tort or otherwise.

• Position all wires to provide room in outlet wall box for device.

• Ensure that the word "TOP" is facing up on the device strap.

• Partially screw in mounting screws in wall box mounting hole.

NOTE:

Dress wires with a bend as shown in diagram in order to relieve stress when

mounting device.

• Restore power at circuit breaker or fuse.

• See applicable operation section to ensure dimmer or switch is functioning properly.

If lights do not turn ON, refer to the TROUBLEShOOTING section.

•

for additional information, contact Leviton’s Techline at

1-800-824-3005 or visit Leviton’s website at www.leviton.com

Covered by one or more US & Foreign Patents and patents pending

Copyright

©

2006 Leviton Manufacturing Co., Inc.

All Rights Including Trade Dress Rights Reserved

Eco-10™ (Eco Series) is a trademark and Hi-lume

®

is a registered trademark of

Lutron Electronics Inc.

PK-93393-10-00-2C

Restore power:

Restore power at circuit breaker or fuse.

Installation is complete.

Step 8

Dimmer Remote Mounting:

TURN Off pOWER AT CIRCUIT BREAkER OR fUSE.

Step 7

Installation may now be completed by tightening

mounting screws into wall box. Attach wallplate.

vZ00R Dimmer Remote Operation (Dimmer may be unlighted):

NOTE:

The lights will turn ON at brightness set on dimmer’s DIM/BRIGHT bar. The

lighting can be controlled from either the dimmer or the remote location.

OpERATION

CLEANING:

Clean with a damp cloth.

DO NOT

use chemical cleaners.

•

Lights flickering

- Lamp has a bad connection.

- Wires not secured firmly under terminal screws of dimmer and/or remote.

•

Light does not turn ON and Locator LED does not turn ON

- Circuit breaker or fuse has tripped.

- Lamp is burned out.

- Lamp Neutral connection is not wired.

•

Intermittent dimmer operation

- Minimum load is under 40W.

•

Remote does not operate lights

- Ensure that total wire length does not exceed 300 ft (90 m).

- Ensure that only Coordinating Remotes are used with Vizia RF devices

TROUBLEShOOTING

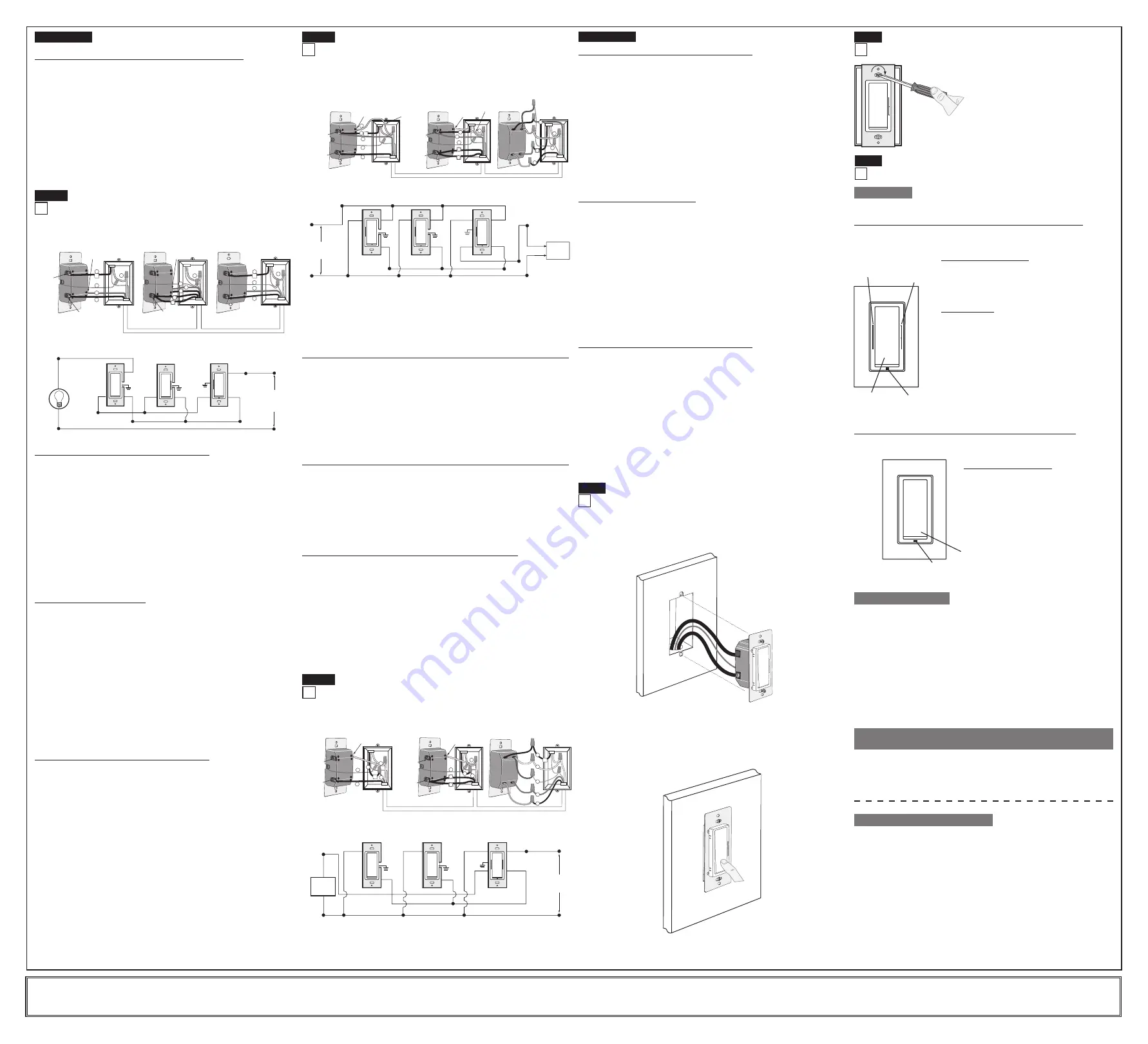

WIRING DIMMER (3-Way wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw or Green dimmer

lead.

• Load wall box wire identified (tagged) when removing old switch to dimmer terminal

screw marked "RD" or the Red dimmer lead.

• First Traveler Line Hot to dimmer terminal screw marked "BK" or the Black dimmer

lead.

• Remove Red insulating label from terminal screw marked "YL/RD" or the Yellow/

Red dimmer lead.

• Second Traveler wall box wire

(note color as above)

to dimmer terminal screw

marked "YL/RD" or the Yellow/Red dimmer lead. This traveler from the dimmer

must go to the terminal screw on the remote marked "YL/RD".

•

proceed to Step 6.

Step 5a cont’d

4-Way Wiring with Matching Remote (w/LEDs)

Application

:

Bk

YL/RD RD

Bk

YL/RD

Wh

RD

Bk

YL/RD

Wh

RD

4

3

3

2

1

5

Terminal

Screw marked

Red (RD)

Terminal

Screw marked

Black (Bk)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Coordinating Remote

(3-Way Wall box from Step 2)

Coordinating Remote

(4-Way Box from Step 2)

Dimmer

(3-Way Wall Box from Step 2)

2

4

3

5

1

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Red (RD)

6

2

1

5

4

hot (Black)

Neutral (White)

Load

Dimmer

Coordinating Remote

(no LEDs)

Coordinating Remote

(no LEDs)

YL/RD

YL/RD

YL/RD

RD

RD

Wh

Wh

RD

Bk

Bk

Bk

Black

not used

White

Line

120vAC, 60hz

not used

not used

Green

Ground

Green

Ground

Green

Ground

Step 5b

4-Way Wiring with Coordinating Remote (no LEDs)

Application:

NOTE:

Incandescent and Magnetic Low-Voltage installations only.

NOTE: Screw terminal dimmer depicted.

WIRING COORDINATING REMOTE (4-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

Maximum wire length from dimmer to last remote is 300 ft (90 m).

• Green or bare copper wire in wall box to Green terminal screw.

• First Traveler and Third Traveler wall box wire

(note wire colors)

to terminal

screw marked "RD". These travelers from the remote in the 4-way box must go to

the terminal screw on the dimmer marked "RD" or Red dimmer lead, and to the

terminal screw marked "RD" of the remaining remote in the 3-way box.

• Second Traveler (tagged) and Fourth Traveler (tagged) wall box wire

(note wire

colors)

to terminal screw marked "YL/RD". These travelers from the remote in

the 4-way box must go to the terminal screw on the dimmer marked "YL/RD" or

the Yellow/Red dimmer lead, and to the terminal screw marked "YL/RD" of the

remaining remote in the 3-way box.

• Remote terminal screw marked "WH" should have White insulation label affixed.

NOTE:

If insulating label is not affixed to terminal screw marked "WH", use

electrical tape to cover. Remote terminal screw marked "BK" is not used. Use

electrical tape to cover.

WIRING DIMMER (3-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

When using the coordinating remote without LEDs, the dimmer can be

installed on either the Line or Load side of the 3-way circuit.

NOTE:

Maximum wire length from dimmer to all installed remotes cannot exceed

300 ft (90 m).

• Green or bare copper wire in wall box to Green terminal screw or Green dimmer

lead.

• Line Hot (common) wall box wire identified (tagged) when removing old switch to

dimmer terminal screw marked "BK" or Black dimmer lead.

• First Traveler wall box wire to dimmer terminal screw marked "RD" or Red dimmer

lead

(note wire color as above)

. This traveler from the dimmer must go to the

terminal screw on the remote marked "RD".

• Remove Red insulating label from terminal screw marked "YL/RD" or Yellow/Red

dimmer lead.

• Second Traveler wall box wire to dimmer terminal screw marked "YL/RD" or Yellow/

Red dimmer lead

(note wire color as above)

. This traveler from the dimmer must

go to the terminal screw on the remote marked "YL/RD".

WIRING COORDINATING REMOTE (3-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

Maximum wire length from dimmer to last remote is 300 ft (90 m).

• Green or bare copper wire in wall box to Green terminal screw.

• Load wall box wire identified (tagged) when removing old switch to terminal screw

marked "BK".

• First Traveler wall box wire

(note color as above)

to terminal screw marked "RD".

This traveler from the remote must go to the terminal screw on the dimmer marked

"RD" or the Red dimmer lead.

• Second Traveler wall box wire

(note color as above)

to terminal screw marked

"YL/RD". This traveler from the remote must go to the terminal screw on the

dimmer marked "YL/RD" or the Yellow/Red dimmer lead.

• Remote terminal screw marked "WH" should have White insulation label affixed.

NOTE:

If insulating label is not affixed to terminal screw marked "WH", use

electrical tape to cover.

•

proceed to Step 6.

BK

YL/RD

WH

RD

BK

YL/RD

WH

4

3

5

Additional

Neutral Wire

4

3

5

1

2

Additional

Neutral Wire

Black

Green

White

Red

Yellow/Red

1

2

4

3

2

Terminal

Screw marked

White (WH)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

6

1

5

Matching Remote

(3-Way Wall box from Step 2)

Matching Remote

(4-Way Box from Step 2)

Control

(3-Way Wall Box from Step 2)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

RD

Hot (Black)

Neutral (White)

Control

Matching Remote

(w/LEDs)

Matching Remote

(w/LEDs)

YL/RD

YL/RD

Yellow/Red

Red

WH

White

WH

BK

BK

Black

Line

120VAC, 60Hz

Black

White

Load

Green

Ground

Green

Ground

Green

Ground

4-Way Wiring with Matching Remote (w/LEDs) for Controls

with Neutral Connection Application:

NOTE:

Electronic Low-Voltage, Mark 10™, Quiet Fan Speed and Electronic

Switch installations only.

NOTE:

Matching remotes are for use with non RF devices only.

NOTE: Dimmer is depicted.

Step 5c

NOTE:

The control must be installed in a wall box that has a Load connection. The

matching remote must be installed in a wall box with a Line Hot connection and a Neutral

connection. A Neutral wire to the matching remote needs to be added as shown.

If you are unsure about any part of these instructions, consult a qualified electrician.

NOTE:

Maximum wire length from control to all installed remotes cannot exceed

300 ft (90 m).

WIRING MATChING REMOTE (4-Way wall box with Line hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw.

• First Traveler and Third Traveler wall box wire to remote terminal screw marked "BK"

in 4-way box, and to terminal screw marked "BK" of the remaining remote in 3-way

box.

• Second Traveler (tagged) and Fourth Traveler (tagged) wall box wire from control in

3-way box to remote terminal screw marked "YL/RD" in 4-way box and to terminal

screw marked "YL/RD" of the remaining remote in 3-way box

(note wire colors)

. This

traveler from the remotes must go to the terminal screw marked "YL/RD" or

Yellow/Red control lead.

• Line Neutral wall box wire to remote terminal screw marked "WH".

WIRING MATChING REMOTE (3-Way wall box with Line hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw.

• Line Hot (common) wall box wire identified (tagged) when removing old switch and

First Traveler wall box wire to control terminal screw marked "BK" or Black dimmer

lead.

• Second Traveler wall box wire from control to remote terminal screw marked "YL/RD"

(note wire color as above)

. This traveler from the remote must go to the terminal

screw marked "YL/RD" or Yellow/Red dimmer lead.

• Line Neutral wall box wire to remote terminal screw marked "WH".

WIRING CONTROL (3-Way wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw or Green dimmer lead.

• Load wall box wire identified (tagged) when removing old switch to terminal screw

marked "RD" or Red control lead.

• First Traveler Line Hot to terminal screw marked "BK" or Black control lead.

• Remove Red insulating label from terminal screw marked "YL/RD" or Yellow/Red

control lead.

• Second Traveler wall box wire

(note color as above)

to terminal screw marked

"YL/RD" or Yellow/Red control lead. This traveler from the control must go to the

terminal screw on the remote marked "YL/RD".

• Line Neutral wall box wire to terminal screw marked "WH" or White control lead.

•

proceed to Step 6.

4-Way Wiring with Coordinating Remote (no LEDs) for Controls

with Neutral Connection Application:

NOTE:

Electronic Low-Voltage, Mark 10™, Quiet Fan Speed and

Electronic Switch installations only.

NOTE: Dimmer is depicted.

Step 5d

WIRING CONTROL (3-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

The control must be installed in a wall box that has a Line Hot connection.

NOTE:

Maximum wire length from control to all installed remotes cannot exceed 300 ft

(90 m).

• Green or bare copper wire in wall box to Green terminal screw or Green control lead.

• Line Hot (common) wall box wire identified (tagged) when removing old switch to

terminal screw marked "BK" or Black control lead.

• First Traveler wall box wire to terminal screw marked "RD" or Red control lead

(note

wire color as above)

.

• Remove Red insulating label from terminal screw marked "YL/RD" or Yellow/Red

control lead.

• Second Traveler wall box wire to terminal screw marked "YL/RD" or Yellow/Red

control lead

(note wire color as above)

. This traveler from the control must go to the

terminal screw on the remote marked "YL/RD".

• Line Neutral wall box wire to terminal screw marked "WH" or White control lead.

WIRING COORDINATING REMOTE (3-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

"BK" and "RD" terminals on coordinating remote are unused. Tighten both

screws.

NOTE:

Maximum wire length from control to last remote is 300 ft (90 m).

• Green or bare copper wire in wall box to Green terminal screw.

• Load wall box wire identified (tagged) when removing old switch to First Traveler

(note

color as above)

.

• Second Traveler wall box wire

(note color as above)

to terminal screw marked

"YL/RD". This traveler from the remote must go to the terminal screw marked "YL/RD"

or Yellow/Red control lead.

• Remove White insulating label from terminal screw marked "WH".

• Line Neutral wall box wire to terminal screw marked "WH".

•

proceed to Step 6.

BK

YL/RD

WH

BK

YL/RD

WH

3

5

1

2

3

4

5

Black

White

Green

Red

Yellow/Red

2

1

1

4

4

3

5

2

Terminal

Screw marked

White (WH)

Terminal

Screw marked

White (WH)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Terminal

Screw marked

Yellow/Red

(YL/RD)

Terminal

Screw marked

Black (BK)

Coordinating Remote

(3-Way Wall box from Step 2)

Coordinating Remote

(4-Way Box from Step 2)

Control

(3-Way Wall Box from Step 2)

6

RD

RD

Hot (Black)

Neutral (White)

Control

Coordinating Remote

(no LEDs)

Coordinating Remote

(no LEDs)

YL/RD

YL/RD

Yellow/Red

RD

White

Red

Black

Black

BK

WH

WH

White

Line

120VAC, 60Hz

RD

not used

not used

not used

not used

BK

Load

Green

Ground

Green

Ground

Green

Ground

WIRING COORDINATING REMOTE (4-Way box):

Connect wires per WIRING DIAGRAM as follows:

NOTE:

"BK" and "RD" terminals on coordinating remote are unused. Tighten both

screws.

NOTE:

Maximum wire length from dimmer to last remote is 300 ft (90 m).

• Green or bare copper wire in wall box to Green terminal screw.

• Connect First Traveler wall box wire to Third Traveler wall box wire

(note wire colors)

to terminal screw marked "RD" of remote in 4-way box, and to terminal screw marked

"RD" of the remaining remote in 3-way box.

• Connect Second Traveler and Fourth Traveler wall box wire

(note wire colors)

to

terminal screw marked "YL/RD" of remote in 4-way box, and to terminal screw marked

"YL/RD" of the remaining remote in 3-way box.

This traveler from the remotes must go to the terminal screw marked "YL/RD" or

Yellow/Red control lead.

• Remove White insulating label from terminal screw marked "WH".

• Line Neutral wall box wire to terminal screw marked "WH".

Step 5d cont’d

Testing your Remote prior to completely

mounting in wall box:

Step 6

push pad (Default settings)

Turn ON from Off position:

Tap – Lights turn ON to preset level.

Press and Hold – Lights turn ON to full bright.

Turn Off from ON position:

Tap – Lights turn OFF.

DIM/BRIGhT Bar

BRIGhTEN:

Press upper half of DIM/BRIGHT Bar – Lights brighten to

desired level.

DIM:

Press lower half of DIM/BRIGHT Bar – Lights dim to

desired level.

If you continue to hold, the lights will DIM to minimum

level and then turn OFF.

If there is a power outage, when the power is restored

the lights will return to the last setting before the power

interruption.

DIM/BRIGhT

Bar

push pad

Locator

Light

LED

Brightness

Display

vZ0SR Switch Remote Operation (Switch may be unlighted):

NOTE:

The lights will turn ON at brightness set on dimmer’s DIM/BRIGHT bar. The

lighting can be controlled from either the dimmer or the remote location.

push pad (Default settings)

Turn ON from Off position:

Tap – Lights turn ON to preset level.

Turn Off from ON position:

Tap – Lights turn OFF.

If there is a power outage, when the

power is restored the lights will return

to the last setting before the power

interruption.

push pad

Locator

Light

This equipment has been tested and found to comply with the limits for a Class B

Digital Device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment OFF

and ON, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving Antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/tv technician for help.

fCC COMpLIANCE STATEMENT