User Manual for BPS-4H (High Temp.)

www.levitronix.com

PL-2009-05, Rev04, DCO# 21-101

34/39

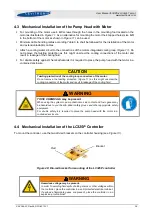

6.4 Impeller Replacement Procedure for Pump Head CP-4.34/36

6.4.1 Preparation

Before starting the impeller exchange procedure,

the parts and tools illustrated in

prepared. Pump head specific impeller exchange

kits, which contain these parts and tools, are

available at

Levitronix

®

.

Figure 34: Parts for impeller of pump head CP-4.34/36

A-H: Parts of impeller exchange kit is IEK-4.10.

a-d: Other parts of pump head.

The following warnings and cautions should be

read carefully before starting the exchange of

the impeller.

!

WARNING

The impeller could splash toxic or corrosive chemicals

because of the strong magnetic forces. Flush the

pump housing before opening it.

!

WARNING

Harmful chemicals may be present.

Skin contact and toxic gases may be hazardous to

your health. Wear safety gloves and other appropriate

safety equipment.

!

CAUTION

The rotating impeller could cause injury. Do not run the

pump system when opening the pump head.

CAUTION

Pay attention to the magnetic forces when handling the

impeller. The attraction of magnetic parts and particles

should be avoided in order to keep the impeller and the

pump head clean and free of contamination.

Housing

Removal Tool

HRT-4.1

G

Impeller Exchange

Tool IET-3.1

Impeller

IMP-4.7

Back-Up Gasket

(ePTFE)

Screw Protection Cup

incl. O-Ring (FKM)

12 pcs. M18x1.5 (PE-HD)

Torque Spec.: 1.5 Nm

Pump Head Screws

incl. Spring Washers

8 pcs. M8x45 (SS)

Torque Spec.: 3.5 Nm

Motor Screws

4 pcs. M8x80 (SS)

incl. Spring Washers

Torque Spec.: 17 Nm

Pipe O-Ring

4 pcs. (FKM)

H

F

Radial

Support

Ring

Axial

Support

Plate

Casing Lid

Casing

Bottom

Screw Protection Pipe

e

E

D

C

a

A

B

d

c

b