User Manual for BPS-200

www.levitronix.com

PL-4012-00, Rev07, DCO# 20-144

19

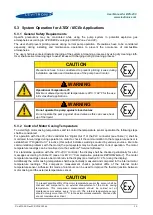

4.1.2 General Installation Instructions

!

WARNING

Hazardous voltage may be present.

Always isolate the electrical power supply before making or changing

connections to the unit.

In case of the usage of an inadequate AC/DC power supply, mains

voltages may be present (even if the system is designed for 24-

48VDC). The usage of a galvanic separated power supply, which is

certified by a 3

rd

party (UL or CE), is highly recommended.

The controller housing must be properly grounded and placed in a spill

protected electrical cabinet. Use one of the DIN-rail screws on the back

side of the controller housing.

Do not use different and longer screws, which may result in short-

circuit within the controller.

1.

The controller casing must be grounded. The screws of the DIN-rail brackets can be used for

grounding (see

).

2.

Connect the motor connector to the controller.

3.

Connect the controller type specific connectors: see

Section 4.1.3

the

LPC-200.1

,

Section 4.1.4

LPC-200.1

and

Section 4.1.5

extended operation with

LPC-200.2

4.

Depending on the required hydraulic operational point (see

), the pump system requires

24V or 48 DC supply voltage at a maximum power of 200 W. At a lower performance power

supplies with smaller power or bigger supplies to supply several pump systems simultaneously

may be used.

to get the power consumption depending on the flow.

Contact

Levitronix for consulting and support on the power supply solution.

5.

Connect the DC supply wires to the power input connector of the controller. Make sure that the

polarity is correct (see

) and that AC/DC power supply is off.

6.

To secure the connectors, tighten all retaining screws.

Figure 22: Grounding of LPC-200 controller