User Manual for BPS-200

www.levitronix.com

PL-4012-00, Rev07, DCO# 20-144

25

5

Operation

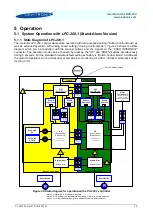

5.1 System Operation with LPC-200.1 (Stand-Alone Version)

5.1.1 State Diagram of LPC-200.1

The controller

LPC-200.1

allows stand-alone operation with manual speed setting (

“Button Control Mode”

) as

well as extended operation with analog speed setting (

“Analog Control Mode”

).

diagram which can be controlled with the manual buttons and the signals on the

“USER INTERFACE”

connector. The operation mode can be choosen by pressing the

“UP”

and

“DOWN”

buttons simultaneously

during 5 seconds. For the standard firmware default setting ex factory is

“Button Control Mode”

. Additionally

the motor temperature can be checked (see temperature monitoring for

ATEX / IECEx

maintenance under

Section 5.3.2

Button Control Mode

Analog Control Mode

Power On

OFF

ButtonControl

ON

(Speed Mode)

ButtonControl

Ref.-Speed set

to stored value*

OFF

AnalogControl

ON

(Speed Mode)

AnalogControl

Ref.-Speed set by

analog input

R

Reset Button

Ref. Speed

UP

Ref. Speed

DOWN

ButtonControl saved

in EEPROM

AnalogControl saved

in EEPROM

!

Error

!

Error

Enable

input = 0V

Enable

input = 0V

Enable

input = 24V

Press up

for 2 sec

Press down

for 2 sec

Press up

for 1 sec

Press down

for 1 sec

If Speed

@ 0 RPM

Press both

for 5 sec

Enable

input = 24V

!

Error

!

Error

Press both

for 5 sec

Press both

for 1 sec

Motor

Temperature

Returns to previously

active mode after

displaying temperature

twice

System Error

ButtonControl

System Error

AnalogControl

R

Reset Button

Press both

for 5 sec

Figure 29: State diagram for operation with LPC-200.1 controller

Note 1: Description is for standard firmware.

Note 2: For Revision < 02 temperature monitoring of motor is not implemented.

Note 3: For other configurations refer to alternate firmware documentation.

Factory default setting