User Manual for BPS-200

www.levitronix.com

PL-4012-00, Rev07, DCO# 20-144

30

5.3 System Operation for ATEX / IECEx Applications

5.3.1 General Safety Requirements

Specific precautions may be considered while using the pump system in potential explosive gas

atmospheres according to

ATEX/IECEx category 3G/3D

(

Zone 2

and

22

).

The user shall prevent priming issues during normal pump operation. Precautions have to be considered

especially during installing and maintenance operations to prevent the occurrence of combustible

atmospheres.

The user shall prevent electrostatic charging of the system at cleaning processes by using dry cleaning cloth.

User shall use wet cleaning rags to avoid issues with charging during a cleaning process.

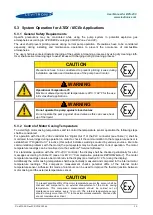

CAUTION

Precautions have to be considered to prevent priming issues during

installation operation and maintenance of the pump head / motor.

!

WARNING

Operational Temperature T5

Maximum allowed pump liquid temperature is 90°C / 194°F for the use

in Ex classified applications.

!

WARNING

Do not operate the pump against closed valves

Do not operate the pump against closed valve as this can cause heat

up of the liquid.

5.3.2 Control of Motor Casing Temperature

To avoid high motor casing temperatures and to control the temperature sensor operation the following steps

shall be considered:

For operation with the

LPC-200.2

controller the “

Digital Out 3

) shall be

monitored for warnings during operation in order to check if the communication to the temperature sensor is

established. If “

Digital Out 3

” is active (this output indicates warnings caused by various sources, inter alia

communication problems with the motor) the pump system may be checked for correct operation. The motor

temperature readings can be monitored via the

Levitronix

®

Service Software

.

For standalone operation with the

LPC-200.1

controller the display shall be checked periodically for error

(

see error

Er10 = “Communication problems EEPROM Motor

”). The motor

temperature readings can also be monitored via the display (see

Section 5.1.2

Additionally the motor casing temperature shall be periodically measured and compared to the internal motor

temperature readings. This comparison measurement checks potential drifts of the internal motor

temperature sensor. Adhesive foil made of aluminum can be used to improve the thermal junction between

motor casing and the external temperature sensor.

CAUTION

To prevent possible drifts of the motor temperature sensor the sensor shall be

checked and compared to an external measurement of the motor casing

temperature. This comparison measurement should be carried out at

maintenance procedures every 12 month. The internal temperature sensor

should not vary more than -10 °C to the external measurements. Positive drifts

are not considered as critical.