User Manual for BPS-i100

www.levitronix.com

PL-4036-00, Rev03, DCO# 21-057

5

System Name

Article #

Pump Head

Driver

Note

BPS-i100.1

100-90719

LPP-200.7

IPD-100.1-50-01

OEM - Epoxy coated driver, 5 m PVC cable with open wires, PFA pump head.

BPS-i100.2

100-90720

LPP-200.7

IPD-100.2-50-01

OEM - ETFE coated driver, 5 m FEP cable with open wires, PFA pump head.

BPS-i100.11

(ATEX)

100-91365

LPP-200.7

IPD-100.10-50-01

(ATEX)

OEM

– ATEX/IECEX - ETFE coated driver, 5 m FEP cable open wires, PFA pump head.

BPS-i100.8

100-91082

LPP-200.7

IPD-100.4-01

EasyConnect - Epoxy coated driver with interface connectors, PFA pump head.

BPS-i100.9

100-91083

LPP-200.7

IPD-100.5-01

EasyConnect - ETFE coated driver with interface connectors, PFA pump head.

BPS-i100.7

100-91041

LPP-200.7

IPD-100.6-01

Stand-Alone - Epoxy coated driver with integrated user panel, PFA pump head.

Table 1: Standard system configurations

Pos.

Component

Article Name

Article #

Characteristics

Value / Feature

1

Pump Head

LPP-200.7

100-90708

Impeller / Housing / O-Ring

In-/Outlet Fittings

PFA / PFA / FFPM (FFKM) perfluorelastomer

1/2” Tube

Max. Flow / Max. Diff.-Press.

Max. Viscosity / Max. Liq.

Temp.

20 liters/min (5.3 gallons/min) / 2 bar (29 psi)

20 cP / 90 °C (194 °F)

3

2a

2b

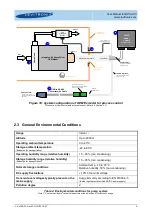

Integrated Pump Driver

(“OEM Models”)

IPD-100.1-50-01

IPD-100.2-50-01

100-10069

100-10071

Voltage, Power

24 VDC ±10%, 100 W

Housing

Cable

Epoxy (a) or ETFE (b) coated Aluminum, PP for bottom lid, IP65

1

PVC (a) or FEP (b) jacket, open wires, cable length 5 m

Interfaces

PLC and RS485 with Modbus protocol.

Standard Firmware

G1.48

2

2c

2d

Integrated Pump Driver

(“EasyConnect” Models)

IPD-100.4-01

IPD-100.5-01

100-10108

100-10109

Housing

Epoxy (c) or ETFE (d) coated Aluminum, PP for bottom lid, IP65

1

Interfaces

2x Fieldbus RS485 with Modbus protocol, PLC and power supply

Standard Firmware

G1.48

2

2e

Integrated Pump Driver

(“Stand-Alone” Model)

IPD-100.6-01

100-10101

Housing

Epoxy coated Aluminum, PP for bottom lid, IP65

1

Interfaces

User panel with 3 user buttons, PLC and power supply

Standard Firmware

G1.48

2f

Integrated Pump Driver

(“OEM” ATEX Model)

IPD-100.10-50-01

100-10154

Housing / Cable

ETFE coated Alu., PP for cup, IP65

1

/ FEP jacket, open wires, 5 m

ATEX / IECEx Marking

II 3G Ex ec h mc IIC T4 Gc /

II 3D Ex h tc IIIC T90°C Dc

Table 2: Specification of standard components

Note 1: Designed and tested for IP67. Note 2: Special firmware for serial pumping as one unit (Figure 6) available on request. Note 3: ATEX driver IPD-100.10 is certified for max 70°C.

Pos.

Component

Article Name

Article #

Characteristics

Value / Feature

3

Impeller Exchange Kit

IEK-200.4

100-90733

Impeller (A) / O-Ring (B)

Pump (C) / Motor Screws (D)

Exchange Tool IET-1.1 (E)

PFA (LPI-200.5) / FFPM (FFKM) with dimensions: 50.52 x 1.78 mm

6x M4 x 16 mm / 8x M3 x 40 mm (stainless steel PTFE coated)

POM-C

4a

AC/DC Power Supply

TSP 180-124 (Traco)

100-40018

Voltage Output / Input

Basic Dimensions

Certification or Standards

24 VDC with 180 W / 85

– 132 and 187 – 264 VAC (autoselect)

110 x 110 x 54 mm (mountable on DIN rail 35 mm)

UL/cUL, CB, Semi F47

4b

Desktop AC/DC Power

Supply

GST160A24-R7B IC915

100-40020

Voltage Output / Input

Basic Dimensions

Safety Approvals

Note

24VDC, 160W / 85

– 264 VAC, 47-63 Hz

175 x 72 x 35 mm

UL60950-1, CSA C22.2, TUV EN60950-1

Connector for direct connection to supply of driver, cable length 1.2 m.

4c

AC Mains Cables

AMC-1.1 (2m) / AMC-1.2 (2.5m)

AMC-1.3 / AMC-1.4 (2.5m)

AMC-1.5 (2.5m)

190-103

31

/

32

190-103

33

/

34

190-10335

Country

Country

Country

US, Canada / CB, Germ., Den., Norw., Finl., Belg., Neth., Sweden, Austria

PSE, Japan / Switzerland

CE, United Kingdom

5

USB to RS485

Adaptor-TR Isolated

YN-485I-TR

100-30392

Structure/Design

USB connector (A) with termination resistor and cable (2m) with connector

pair (B and C) for external RS485 wire connection. Magnetically isolated.

Cable length is 2m. Included is a USB space saver cable (D).

Purpose

Communication over fieldbus of driver with PC

6

IPS Cable Power 2

Wires

ICP-2.1-50 (5 m)

190-10370

Cable Material / Wires

Connection In / Out

Main Purpose

PVC jacket / 2x 1.5 mm

2

Open wires / Circular Intercontec type to driver

Connection of power supply to “Stand-Alone” and “EasyConnect” drivers

7a

IPS Cable Signal 6

Wires

ICS-1.1-02 (0.2 m)

ICS-1.1-10 (1 m)

ICS-1.1-30 (3 m)

190-10381

190-10344

190-10345

Cable Material / Wires

Connection In / Out

Main Purpose

PVC jacket / 6x 0.08 mm

2

and shielding

Circular Hirose type / Circular Hirose type

Fieldbus connection between “EasyConnect” drivers (multi-pump arrays)

7b

IPS Cable Signal 6

Wires

ICS-1.2-50 (5 m)

190-10346

Cable Material / Wires

Connection In / Out

Main Purpose

PVC jacket / 6x 0.08 mm

2

and shielding

Connector with screw type plug for open wire connection / Circular type

Fieldbus to “EasyConnect” drivers and to PLC of “Stand-Alone” drivers.

8

IPS Cable Signal 12 Wires ICS-2.1-50 (5 m)

190-10347

Cable Material / Wires

Connection In / Out

Main Purpose

PVC jacket / 12x 0.14 mm

2

and shielding

Connector with screw type plug for open wire connection / Circular type

General connection to PLC of “EasyConnect” drivers.

9a

9b

9c

9d

Chemical Protection

Connector Cover

CPC-1.1

CPC-1.2

CPC-1.3

CPC-1.5

190-10349

190-10350

190-10351

190-10352

Materials, IP-Rating

Main Purpose of

CPC-1.1

Main Purpose of

CPC-1.2

Main Purpose of

CPC-1.3

Main Purpose of

CPC-1.5

PP+GF30 and FPM/FKM for sealing gaskets, IP65

1

Chemical protection of driver connectors of ICS-1.x cables.

Chemical protection of driver connectors of ICS-2.x cables.

Chemical protection of driver connector for supply with ICP-2.1 cable.

Chemical protection of fieldbus termination connector FTC-1.1

10

Fieldbus Termination

Connector

FTC-1.1

190-10348

Materials

Main Purpose

PPS for connector housing and FPM for sealing.

Termination of fieldbus.

11

ATEX Cable

Sealing System

ACS-A.1

(Roxtec)

100-90292

Sleeve (A) and Gasket (B)

Frame (C)

2x Cable Module (D)

Stainless Steel and EPDM

Roxylon (EPDM rubber)

Roxylon (EPDM rubber)

Note:

Lubricant (E) and measurement plates

(F) are included.

12

User Panel

LUI-B.1-01

100-30448

Interface / Housing Rating

Standard Firmware

RS485 / IP65

A3.00

13

Water Cooling Module

WCM-i100.1

190-10474

Materials

Motor Mounting Screws

Cooling Flow

Pressure Drop / Max. Press.

Purpose

PTFE coated stainless steel for cooling plate (A) and mounting screws (B).

2x M4x16, stainless steel PTFE coated

Min. 0.5

l/min at ≤ 20 °C. In- and outlet are NPT 1/8” x 6.7mm.

20 mbar for 1 l/min cooling flow (for water at 20 °C) / 4 bar

Driver cooling for higher liquid temperatures (see user manual).

Table 3: Specification of accessories