User Manual for BPS-iF100

www.levitronix.com

PL-4037-00, Rev02, DCO# 21-057

24

4.2.2 Mechanical and Hydraulic Installation of Flow Sensors

1. In order to fix the sensor body 2 fixation holes can be used for the

LFS-04/08

) and

4 threads for the

LFS-20

see max. torque specification in

). Mechanical

stress on the tube fittings has to be avoided as it might influence the measurement.

2. Assure that at the mounting location the allowed ambient temperature and humidity ranges are not

3. The flow circuit should be completely filled with fluid. The converter DSP (Digital Signal Processor)

contains special algorithms, which increase the robustness of the measurement against bubbles. However,

assure that excessive bubbles are avoided in the circuit. If bubbles are expected in the loop it is highly

recommended to use z-shape versions of the flow sensors.

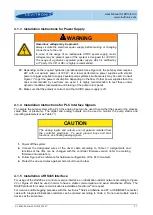

4. Ideal mounting position for the flow sensor is 45° (see

) with upward flow direction to avoid the

stagnation of bubbles and particles in the measuring tube.

Figure 24: Mounting position of flow sensor

(With U-shape stagnation zones for bubbles can not be avoided. Usage of z-shape recommended in case excessive bubbles.)

5. An arrow mark on the flow sensor (see

) indicates the flow direction (see also

). Make sure that the arrow corresponds to the direction of the flow in the hydraulic circuit.

6. Avoid excessive vibrations such as in the neighborhood of displacement pumps. Insufficient contact of the

transducer (within the sensor) onto the pipe wall caused by vibration may result in inaccurate

measurement.

7. The flowmeter measures flow velocity. In order to obtain fully developed flow pattern for accurate velocity

measurement, straight run of 10x sensor ID upstream and of 5x ID downstream is recommended (for ID

specifications of the sensor models see

). If non-uniform turbulent flow or swirl flow

is expected, install longer upstream straight run and/or a flow-rectifier.

8. To install on pipe that has open end, the sensor should be mounted in lower position of the pipe line.

9. The sensor should be mounted where pressure in the pipe is above the atmospheric pressure (preferably

at the outlet of the pump head).

10. Devices like valves are recommended to be installed downstream of the sensor in order to prevent

formation of bubbles in the liquid. An upstream valve may form bubbles reducing the intensity of the

ultrasound signal and interfering with measurement.

11. A bypass pipe run (including bypass valve and shutoff valve) is recommended for easy zero adjustment

and maintenance.

12.

After setup a “Zero Adjust” is recommended. Assure that the sensor is completely filled with the according

fluid and is free of bubbles. Stable liquid properties should be assured by flushing the circuit with the final

liquid until temperature and viscosity becomes stable. After this zero flow shall be realized. Use the

relevant digital input on the

PLC

) or the

Levitronix

®

Service Software

to start the

Zero Adjust process.

13. If zero adjustment is regularly necessary, automation is possible over the digital input of the driver PLC or

the fieldbus.

14. In the following cases a zero adjustment is recommended:

a.

30 minutes after power-on of a cool converter and sensor

b.

Change of fluid properties (temperature, viscosity, density)

c.

Change of chemistry

d.

Change of the hydraulic circuit

Horizontal Mounting Position:

Stagnation of Bubbles and

Particles

45

0

Mounting Position:

Free flow of bubbles and

particles