User Manual for PuraLev

®

600MU

www.levitronix.com

PL-4033-00, Rev09, DCO# 20-144

28

4.4 Mechanical Installation of the Controller

!

WARNING

Hazardous voltage may be present.

In order to avoid fluid spills shorting mains or other voltages within the

controller, place the controller in a spill protected environment (for

example protected electronic cabinets).

If explosive flammable gases are present, place the controller in an

explosion-proof cabinet.

CAUTION

Make sure the controller is mounted in a position that allows free air

circulation around the controller. A minimum distance of 10cm

(4”) to

other objects above or below the controller casing is recommended.

•

Use the DIN-rail bracket to mount the controller.

•

If no forced air-cooling is used, mount the controller in upright position.

•

The DIN-rail brackets can also be mounted on the controller side according to

CAUTION

Use only 3.5 x 6.5 mm self-tapping screw for the fixation of the DIN-rail

brackets.

The controller may be damaged if other type or too long screw

types are used!

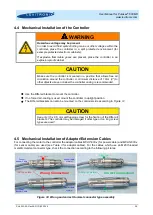

4.5 Mechanical Installation of Adaptor/Extension Cables

For connecting the motor to the controller the adaptor cables

MCAP-600.x

(for power cable) and

MCAS-600.x

(for sensor cable) are used (see

for adaptor cables). For the cables which use an M23 threaded

metallic Hummel connector type, check the connection according to the following pictures:

Figure 33: Wrong and correct Hummel connector type assembly

O-Ring visible

Wrong Connection!

O-Ring not visible

Correct Connection!

Gap > 2 mm

Sensor Cable

of Motor

Power Cable

of Motor

Gap > 1 mm

Gap

1 mm

Gap

2 mm

Sensor

Adaptor Cable

Power

Adaptor Cable