CARE

20

CARE

21

Removing the Shading

• Fully raise the shading.

• Disconnect the power source from the power cable

at the back of the shading.

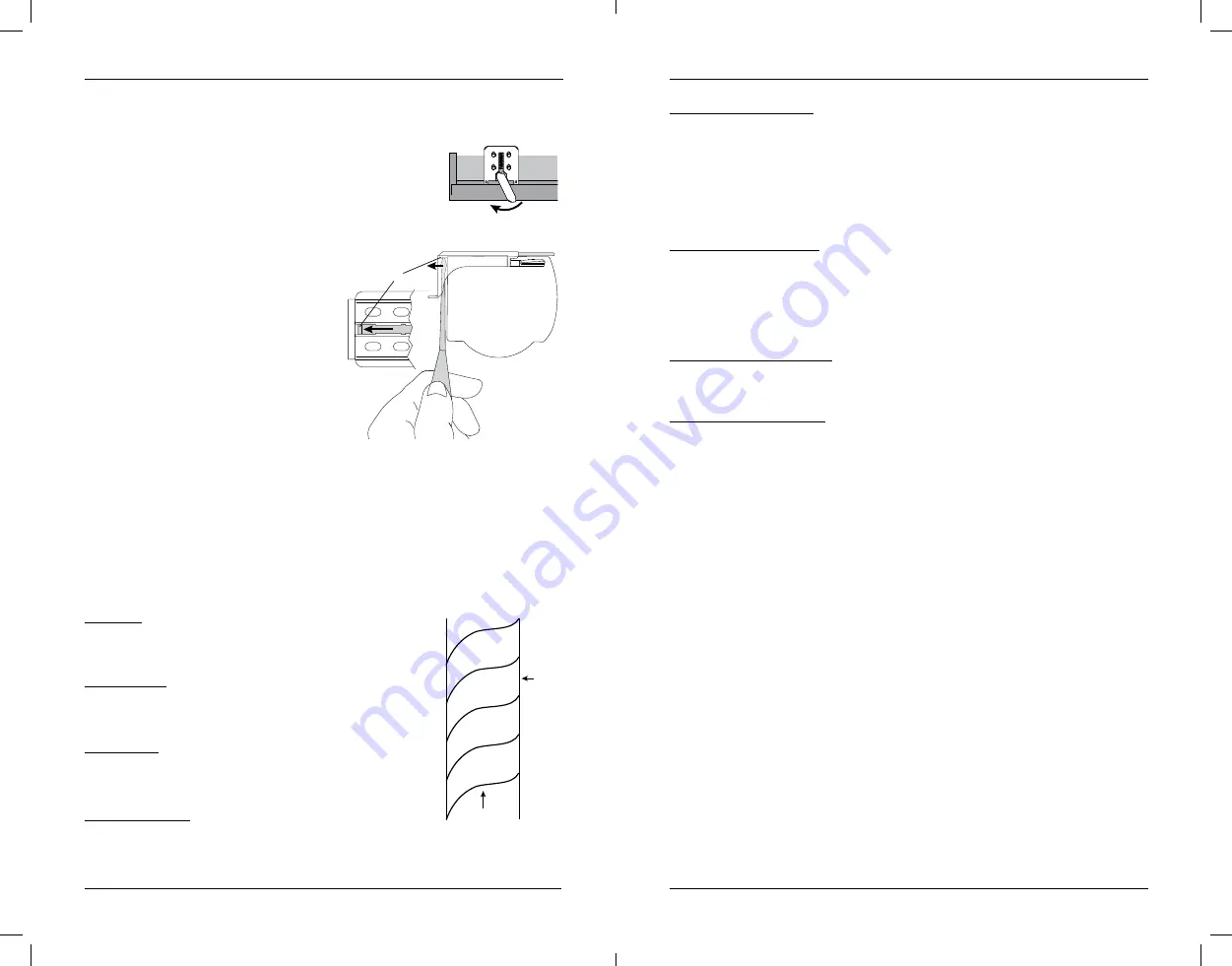

• Move the lever on the installation brackets to the left

to release the shading.

— A flat head screwdriver can be

used to move the lever.

— If the lever is inaccessible or

inoperable, lower the shading

until you can see the underside

of the bracket. Carefully reach

a small flat head screwdriver

behind the shading to the

tab on bottom of the bracket

between the screw holes.

— Push the tab away from the

shading and pull the headrail

to release it from the bracket.

CAUTION:

Be very careful to not tear or damage any of the fabric.

• Carefully pull the shading to remove it from the brackets.

Cleaning Procedures

Sheer shadings are made of 100% polyester, which means they are inherently durable

and resilient. However, care must be taken to avoid wrinkling the fabric, particularly

where the vanes meet the facings.

Dusting

• Regular light dusting with a feather duster is all the cleaning

that is needed in most circumstances.

Vacuuming

• Use a low suction, hand-held vacuum for more thorough

dust removal.

Forced Air

• Blow away dirt and debris between the vanes using clean

compressed air.

Spot-Cleaning

• Do NOT spot-clean sheer shadings.

Move Lever to Left

Top View

Tab

Installation Bracket

Underside of

Bracket

End Cap

Ultrasonic Cleaning

Sheer shadings can be ultrasonically cleaned by a professional with the

exception of light-dimming fabrics.

• Specify that a mild detergent solution be used.

• Never immerse the headrail in the solution.

• Dry the shading completely in the lowered position.

Injection/Extraction

Sheer shadings can be professionally cleaned using the injection/extraction method.

• A dry method of injection/extraction is required for light-dimming fabrics.

• Never immerse the headrail in the solution.

Electrostatic Cleaning

Do not use electrostatic cleaning wipes on any sheer shadings.

A Note About Fabrics

As with all textiles, sheer shading fabrics are subject to some variations. Slight

wrinkling, puckering, or bowing is inherent to this textile product and should

be considered normal, acceptable quality. These characteristics are not usually

visible from the front or rear but may be visible from a side angle.

Precautions should be taken to reduce exposure to harsh environmental

elements, such as salt air. Continuous exposure through open windows and

doors will accelerate the fabric deterioration.

NOTE

: Improper cleaning may void warranty.

Warranty

For complete warranty information visit levolor.com or call customer service

at 1-800-538-6567.

Battery-Powered Motorized Operating System

Battery-Powered Motorized Operating System

Facing

Vanes

18-0053-026_Sheer_Motorized_Install_Guide_F_wu.indd 20-21

2/26/19 10:37 AM