General information

1-3

4036-402

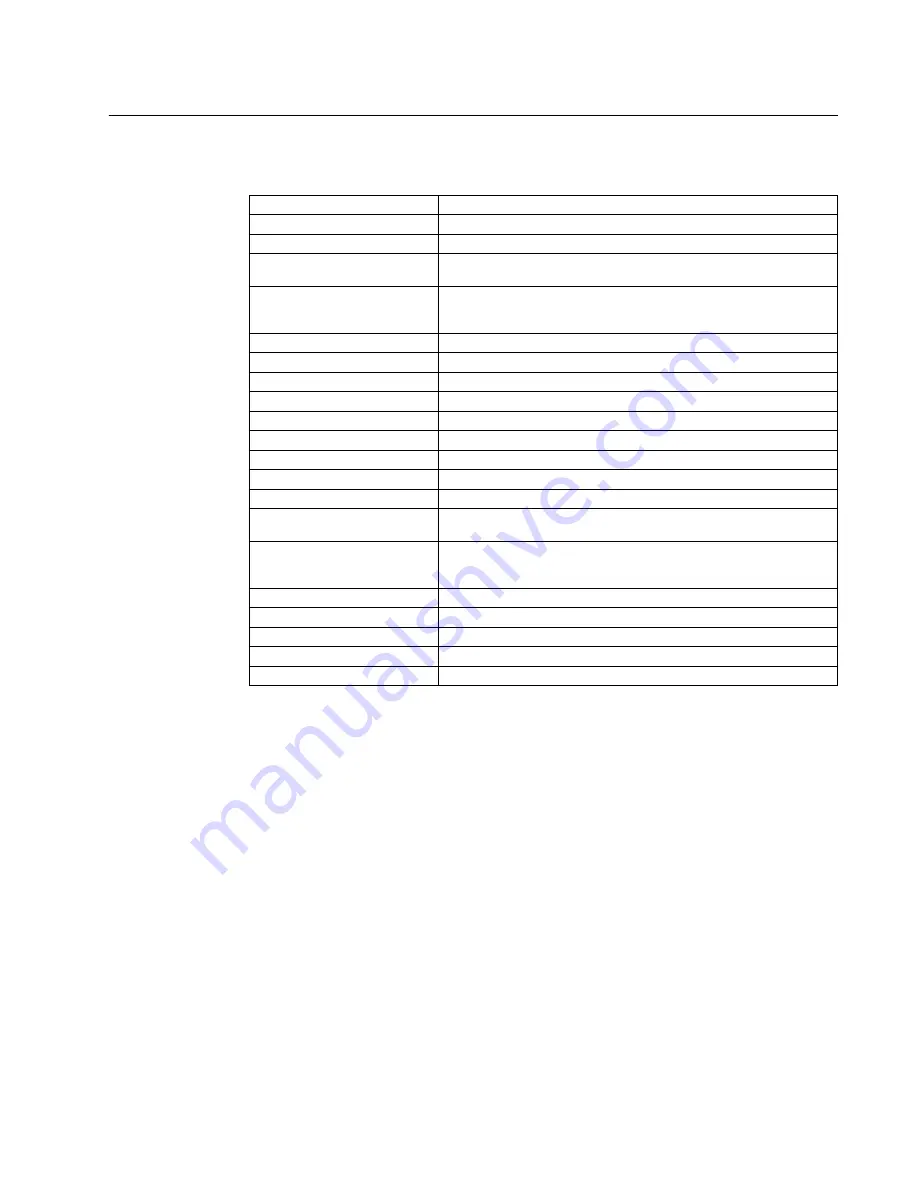

Product specifications

The scanner is designed to meet the following product specifications:

Scanner type

Flatbed scanner with ADF built in

ADF capacity

50 sheets 75g/m² (20 lb)

Media weight

60 g/m² (16 lb) to 120 g/m² (32 lb)

Optical resolution

Flatbed: 600 x 600 dpi

ADF: 600 x 600 dpi

Scan speed

19 ppm for black and white text or mixed input

27 ppm for color input, single page scanning

25 ppm for color input, duplex

Scan method

Color charge-coupled device (CCD)

Light source

Cold cathode fluorescent lamp (CCFL)

Scan area

ADF and flatbed: Max. 297 mm x 432 mm (11.7 x 17 in.)

Display

640 x 480 color VGA touch screen

Image types

1-, 8-, 24-bit with image processing

Scan accuracy

Flatbed ADF

Leading edge

<-1 ~ +2 mm <2 ~ +2 mm

Side edge

<-1 ~ +2 mm <2 ~ +2 mm

Skew

<1 mm <2 mm

Magnification rate tolerance

(horizontal and vertical)

-1.0% ~ +1.0% -1.5% ~ +1.5%

Physical dimension

Height: 419 mm (16.5 in.), measuring to top of ADF feed tray

Width: 660mm (26 in.)

Depth: 686mm (27 in.

Weight

25.7 kg (56.5 lb)

Memory

128MB DRAM

Hard disk drive

10GB or greater

Fax modem

33.6 bps

Paper feed

Face up long edge feed (LEF)

Summary of Contents for 16C0365 - 5500 MFP

Page 49: ...Repair information 3 25 4036 402 3 Remove the pick pad ...

Page 55: ...Repair information 3 31 4036 402 5 Disconnect the cables 6 Remove the user interface ...

Page 68: ...3 44 Service Manual 4036 402 ...

Page 69: ...Connector locations 4 1 4036 402 4 Connector locations Locations Paper path and sensors ...

Page 70: ...4 2 Service Manual 4036 402 Internal view ...

Page 76: ...5 4 Service Manual 4036 402 ...

Page 78: ...6 2 Service Manual 4036 402 Assembly 1 Upper Scanner ...

Page 86: ...I 4 Service Manual 4036 402 ...