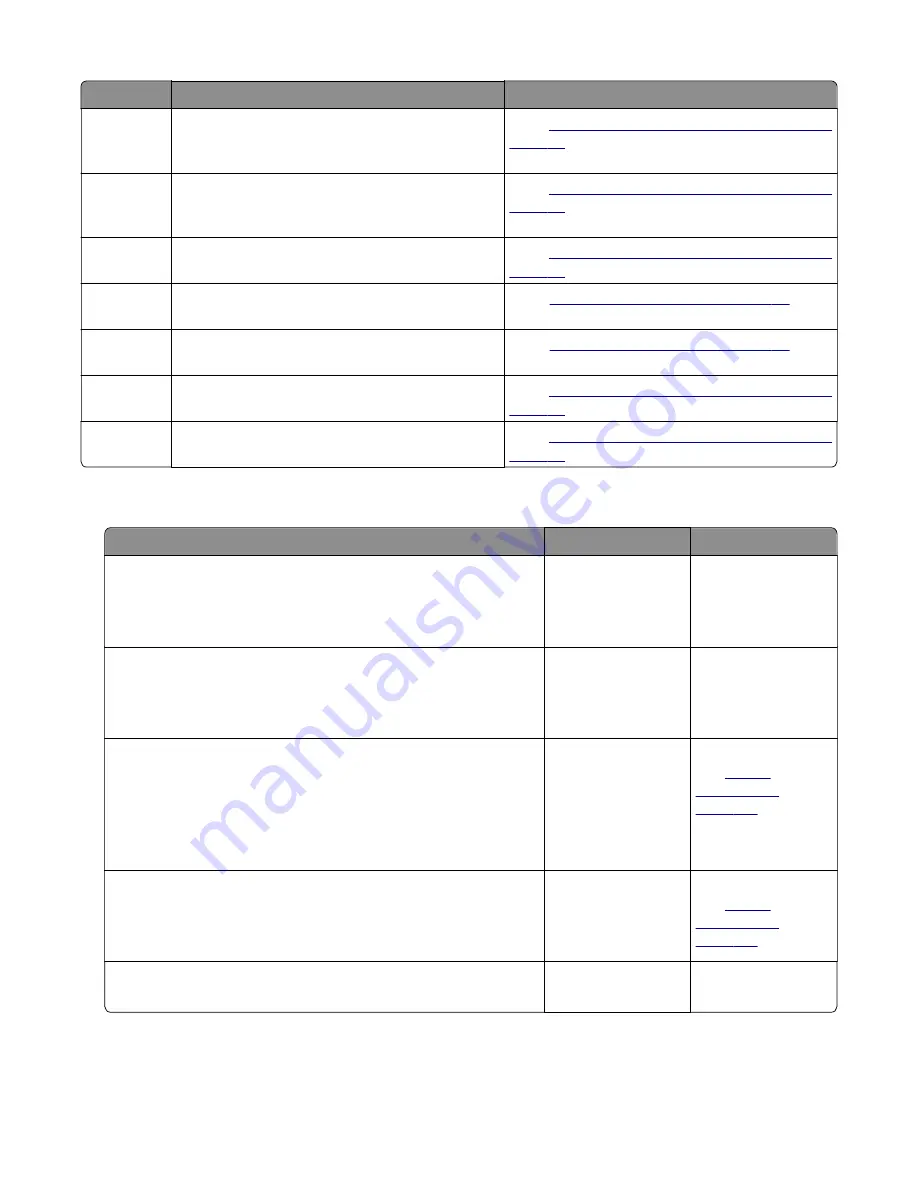

Error code

Description

Action

202.17

Page at fuser nip before fuser reached acceptable

operating temperature. Page arrived at fuser

earlier than expected, so it was probably staged.

“Sensor (fuser exit) jam service check” on

202.22

Cartridge Motor - Motor Underspeed Error. Motor

made it to closed loop steady state, but then

detected speed was below threshold.

“Sensor (fuser exit) jam service check” on

202.28

Exit sensor bounce issue.

Go to

“Sensor (fuser exit) jam service check” on

202.32

The sheet is too long to be duplexed. The blow

through is enabled.

“Duplex service check” on page 98

.

202.36

Long paper or shingled multi feed stopped before

sending to duplex.

“Duplex service check” on page 98

.

202.43

During warm up flush, media that passed the input

sensor failed to reach the exit sensor.

“Sensor (fuser exit) jam service check” on

202.45

During warm up flush, sheet detected too long

over exit sensor.

“Sensor (fuser exit) jam service check” on

Sensor (fuser exit) jam service check

Action

Yes

No

Step 1

Check the input sensor area for jammed media fragments.

Is the paper path free of partially fed or jammed media?

Go to step 2.

Clear the paper path

of any media

fragments.

Step 2

Check the fuser exit sensor cable JEXIT1 for proper connection.

Is it properly connected?

Go to step 3.

Reseat the cable.

Step 3

POR into the Diagnostics menu and perform a sensor test:

Diagnostics Menu

>

Base Sensor Test

>

Exit

Does the sensor state on the control panel display change when

it is toggled?

Go to step 4.

Replace the fuser.

See

Step 4

Check the fuser gears and rollers for damage.

Are they free of damage?

Go to step 5.

Replace the fuser.

See

Step 5

Does the error remain?

Contact the next

level of support.

The problem is

solved.

4514-6xx

Diagnostics and troubleshooting

97

Summary of Contents for M3150

Page 12: ...Part name index 393 4514 6xx Table of contents 12 ...

Page 20: ...4514 6xx 20 ...

Page 38: ...4514 6xx 38 ...

Page 172: ...4514 6xx 172 ...

Page 246: ...3 Remove two screws A and then remove the cooling fan mount A 4514 6xx Parts removal 246 ...

Page 256: ...5 Remove the four screws B and then remove the right front mount B 4514 6xx Parts removal 256 ...

Page 260: ...b Set the spring over the plunger 4514 6xx Parts removal 260 ...

Page 277: ...3 Squeeze the latches B to release the left and right links B 4514 6xx Parts removal 277 ...

Page 300: ...3 Place the printer on its rear side 4 Release the sensor flag A 4514 6xx Parts removal 300 ...

Page 301: ...5 Remove the screw B 6 Remove the sensor flag bracket C 4514 6xx Parts removal 301 ...

Page 323: ...3 Swing the right cover backward to remove 4 Remove the screw D 4514 6xx Parts removal 323 ...

Page 333: ...4514 6xx 333 ...

Page 335: ...Assembly 1 Covers 4514 6xx Parts catalog 335 ...

Page 338: ...4514 6xx Parts catalog 338 ...

Page 339: ...Assembly 2 Electronics 1 1 2 3 4 5 7 9 10 11 6 8 12 4514 6xx Parts catalog 339 ...

Page 342: ...4514 6xx Parts catalog 342 ...

Page 343: ...Assembly 3 Electronics 2 4 3 2 1 5 6 8 9 7 4514 6xx Parts catalog 343 ...

Page 345: ...4514 6xx Parts catalog 345 ...

Page 346: ...Assembly 4 Frame 10 11 12 13 14 9 1 5 6 7 8 4 4 2 3 4514 6xx Parts catalog 346 ...

Page 349: ...Assembly 5 Option trays 3 4 5 6 1 2 4514 6xx Parts catalog 349 ...

Page 354: ...4514 6xx Parts catalog 354 ...

Page 356: ...4514 6xx Parts catalog 356 ...

Page 364: ...4514 6xx 364 ...

Page 376: ...4514 6xx 376 ...

Page 386: ...4514 6xx Index 386 ...

Page 392: ...4514 6xx Part number index 392 ...

Page 398: ...4514 6xx Part name index 398 ...