2-8

Service Manual

4069-XXX

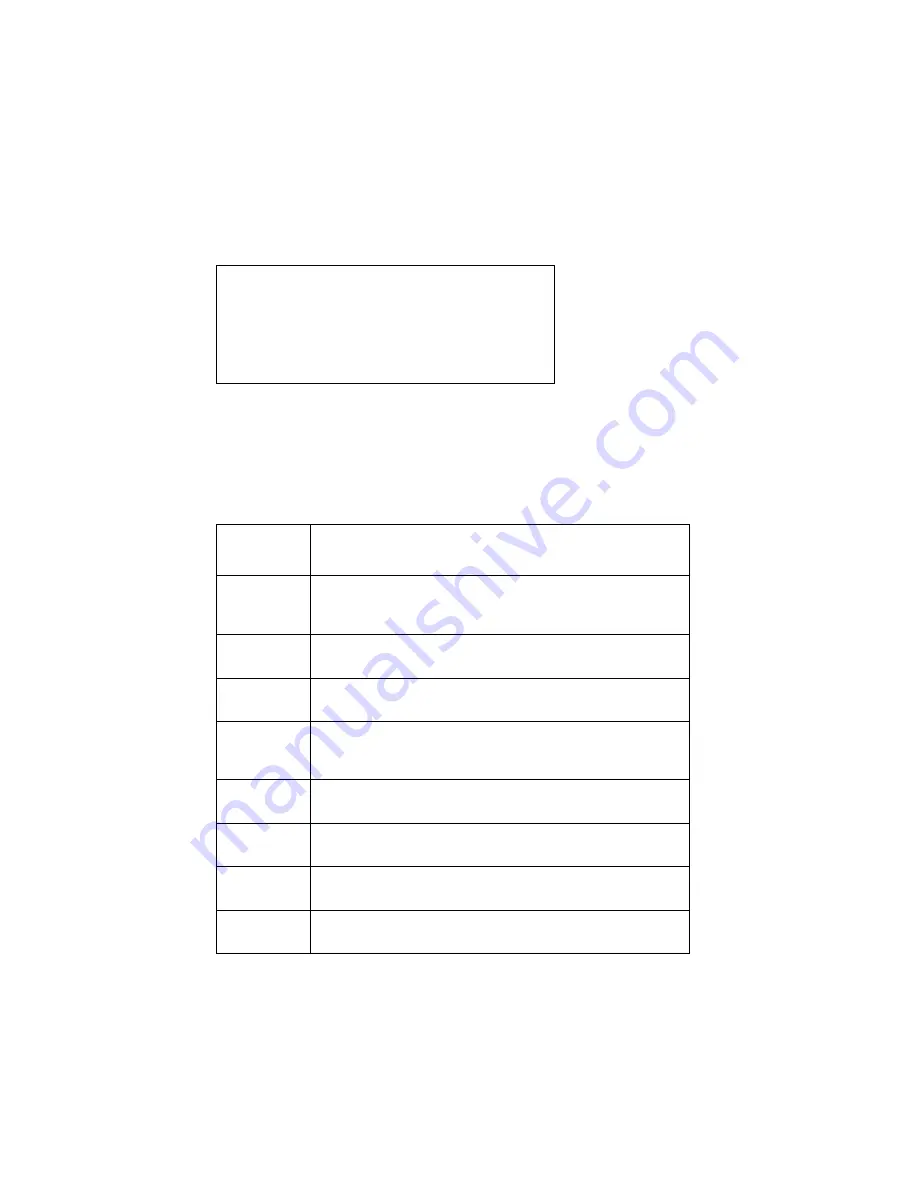

The following is an example of how the printer displays a duplex unit

sub error code.

Base Printer Sub Error Codes

Each status byte has a different level of troubleshooting value for

each area of the printer. The following table displays status bytes 1,

2 and 3. This set of status bytes is designed to help isolate paper

jams and paper feed problems in the base printer.

DU

DU

Byte 1

XX

XX

Byte 5

Byte 2

XX

XX

Byte 6

Byte 3

XX

XX

Byte 7

Byte 4

XX

XX

Byte 8

Status

Bytes 1, 2,3

Explanation

84 xx 00

The input sensor is still covered by the first sheet of paper

through the printer and the second sheet is ready to arrive at

the sensor.

84 xx 01

Video information has not started on the page at the input

sensor within two inches after activating the input sensor flag.

84 xx 02

The media takes too long to complete a pass through the

input sensor.

84 xx 04

This can occur when a sheet of paper is in the machine

during POST and the input sensor flag has tripped the input

sensor.

84 xx 05

This error is generated whenever media is seen at the input

sensor before the sensor flag activates the input sensor.

84 xx 06

A paper jam is detected by the tray you are trying to feed

from.

84 xx 07

A paper jam is detected by a smart option and an error

message displays.

84 xx 08

Paper Tray 5 pass thru sensor is not activated by a sheet of

paper.