GA 12.107/5.02 - 12/97

Spare parts

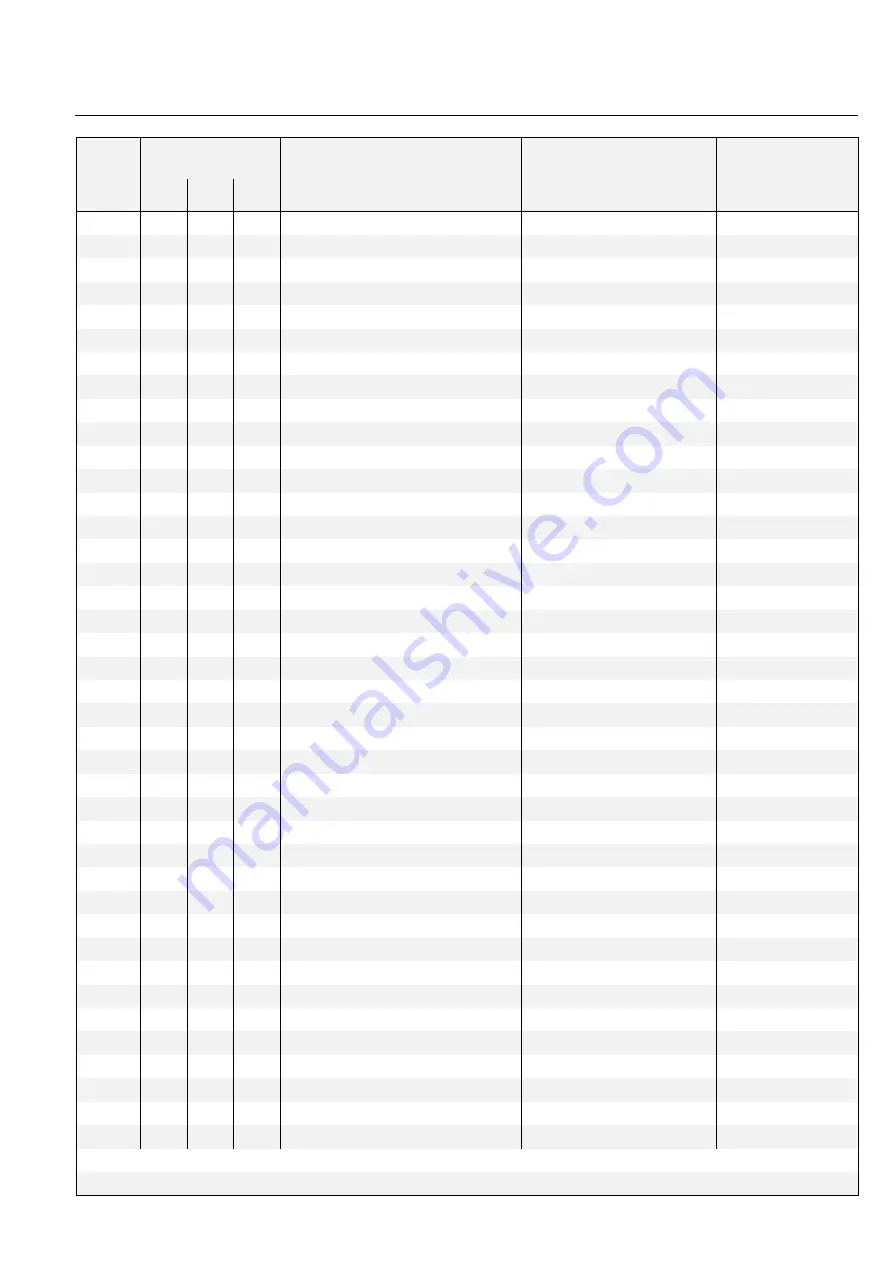

25

1

1

Compressor

CHN1

200 20 160*)

2

1

Power Module

High voltage

200 80 580*)

3

1

Push button

200 80 360

4

2

Light emitting diode

24 V DC

200 80 362*)

5

1

Press-switch

3 A

200 80 363*)

6

2

Hose nipple

DN 12; Ms

200 19 460

7

2

Angle screw fitting

M 16 x 1 x 12; Ms

200 20 932

8

2

Nut

M 16 x 1

200 20 933

9

4

Spring ring

ø 12 mm

200 20 934

10

1

Gasket

5,4 x 9,3 x 3,2; Cu

234 50 217*)

11

1

Pressure gauge

0 - 40 bar

200 19 849*)

12

1

Housing

IP 54

200 80 011*)

13

1

Jack

380 V/ 10 A; 4 pol.

200 80 009*)

14

3

Cage

M 10 x 1; IP 54

200 80 419

15

1

Thermal switch

38

°

C

200 49 098

16

1

Capillary tube

200 20 154*)

17

1

Thermal switch

150

°

C

200 49 096

18

1

Oil filter

390 26 017*)

19

1

Heat exchanger

3 cartridges

200 20 937*)

20

1

Low-pressure line compl.

200 20 204*)

21

2

Aeroquip-coupling

950 00 003*)

22

2

Gasket ring

17 x 1,9 mm

350 20 704*)

23

1

Adsorber

ARW2

891 84

24

2

Separator

200 20 455*)

25

1

Fan

24 V DC

380 91 004

26

1

Safety switch

10 - 16 V

200 80 277*)

27

1

Contactor

24 V DC

200 80 276*)

28

1

Set of transformers

High Voltage

200 81 088*)

29

2

Automatic circuit breaker

0,6 A

200 80 418*)

30

1

Automatic circuit breaker

3 A

200 80 417*)

31

1

PCB

200 80 583*)

RW

6000-1

Item

Description

Ref. No.

Quantity

Characteristics

components identified with an asterisk *) may be replaced only by the LEYBOLD service department

or by personnel specially trained by LEYBOLD for this work

Summary of Contents for RW 6000-1

Page 23: ...GA 12 107 5 02 12 97 Notes 23...