Chapter 10. INSTALLATION AND WIRING

10 - 5

(6) Terminal block

Check its fixing. During drilling or wiring, do not allow any wire scraps to enter into the PLC. It can cause

malfunction and fault.

(7) Be cautious that strong shock does not applied to the I/O module. Do not separate the PCB from its

case.

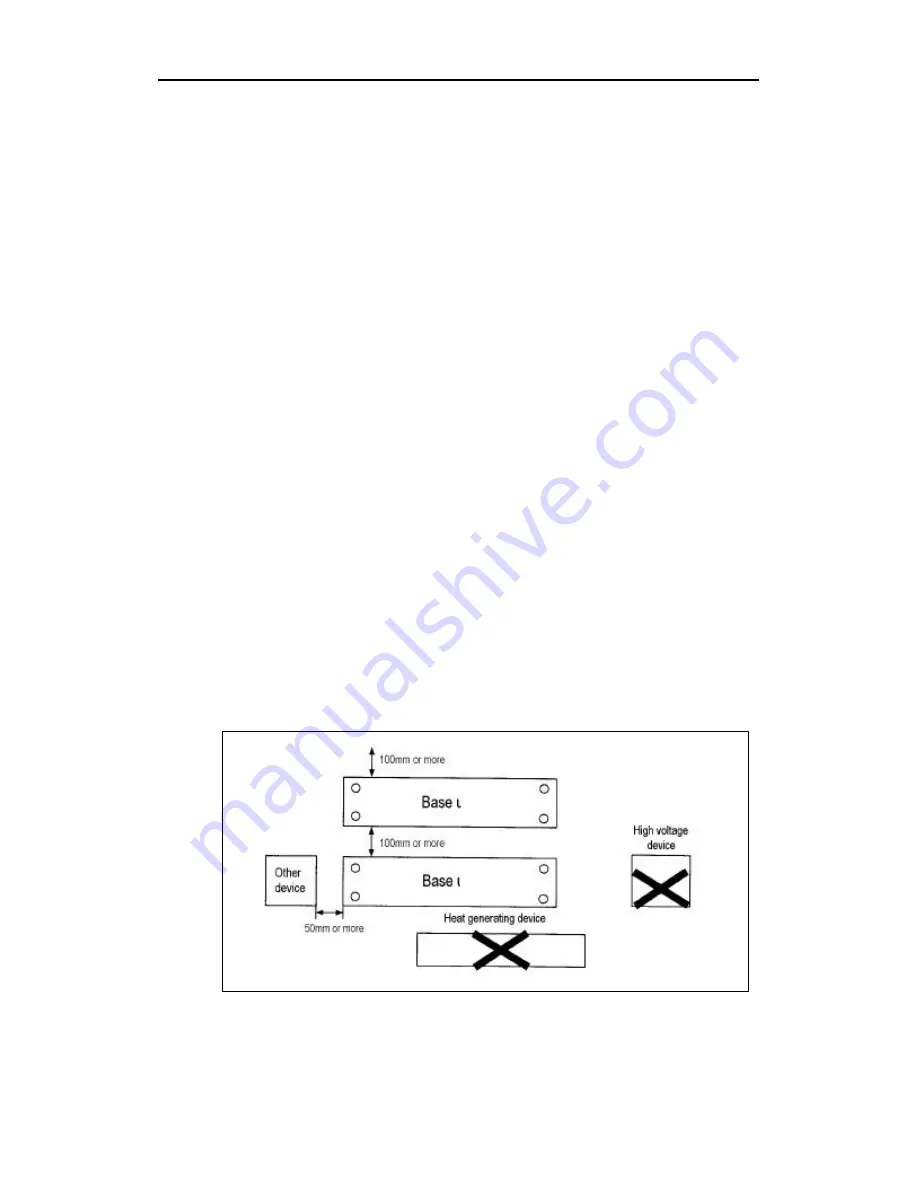

2) Base board mounting instructions

The following explains instructions for mounting the PLC onto the control panel.

(1) Allow sufficient distance from the upper part of the module for easy module replacement.

(2) Do not mount the PLC in a vertical or horizontal position because it affects on ventilation.

(3) Do not mount the base board together with a large-sized electromagnetic contact or no-fuse breaker,

which produces vibration, on the same panel. Mount them on different panels, or keep the base board

away from such a vibration source.

(4) Mount the wire duct as it is needed.

If the clearances are less than those in Fig 10.1, follow the instructions shown below.

•

If the wire duct is mounted on the upper part of the PLC, make the wiring duct clearance 50mm or

less for good ventilation. Also, allow the distance enough to press the hook in the upper part from

the upper part of the PLC.

•

If the wire duct is mounted on the lower part of the PLC, make optic or coaxial cables contact it and

consider the minimum diameter of the cable.

(5) To protect the PLC from radiating noise or heat, allow 100 mm or more clearances between it and

parts. Left or right clearance and clearance from other device in the left or right side should be 50 mm

or more.

board

board

[Fig. 10.1] PLC mounting