- 8 -

Copyright ©

LG Electronics Inc. All rights reserved.

Only training and service purposes.

Insert HDMI Jack which is connected with PC for White Bal-

ance or equivalent device.

→

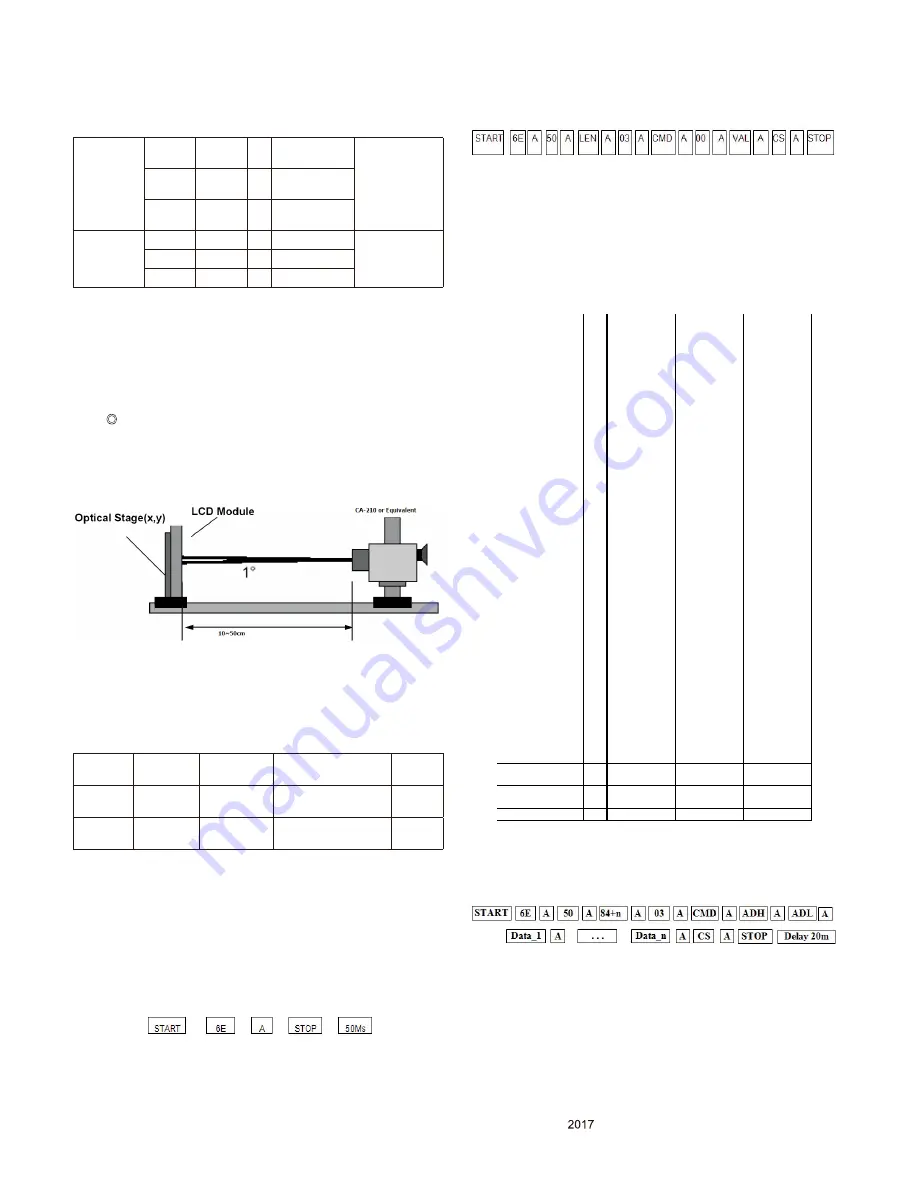

Total Assembly line should check whether the color

coordinate(x,y) data refer to below table were meet or not.

*Note : x,y coordinates are drifted about 0.007 after 30 mins

heat-run. So checking color coordinate within 5-min at

total assembly line, consider x,y coordinates might be

up to 0.007 than x,y target of each color temperature.

* Note : Manual W/B process

1) Power of

f => Power on (‘←

’

3 times, ‘→

’ 1 time and push ‘

’)

2) and push the “←” or “→”.

3) In Service Menu.

* When doing Adjustment, Please make circumstance as

below.

4.3. DPM Operation check

■ Measurement Condition: 100 ~ 240 V @ 50/60Hz

(1) Set Input to DVI-D, DisplayPort, HDMI1, HDMI2

(2) Turn off the source device.

(3) Check DPM operation refer to the below table.

5. Signal composition for adjustment

5.1. I2C (100K BPS)

5.2. COMMUNICATION START

# Until ACK BIT goes LOW, Repeat it.

5.3. Command form.

Command form use DDC2AB standard communication

protocol.

a. LEN : DATA BYTE number to send.

b. CMD : Command language that monitor executes.

c.

V

AL : FOS DATA

d. CS : Dada’s CHECHSUM that transmit

e. DELAY : 50MS

f. A : Acknowledge

5.4. Screen adjust command (LENGTH = 84)

5.5. EEPROM Data Write

5.5.1 Siganl TABLE

LEN : 84h+Bytes

CMD : E8h

ADH : E2PROM Slave

Address(A0,A2,A4,A6,A8,AA,AC,AE),

Not 00h(Reserved by Buffer To EEPROM)

ADL : E2PROM Sub

Address(00~FF)

Data : Write data

Delay : 20ms

Color

Temperature

Cool

9,300

°K

X=0.283 (±0.03)

Y=0.298 (±0.03)

<Test Signal>

Inner pattern

(255gray,80IRE)

Medium

8,000

°K

X=0.295 (±0.03)

Y=0.305 (±0.03)

Warm

6,500

°K

X=0.313 (±0.03)

Y=0.329 (±0.03)

Luminance

(cd/m²)

Cool

Min : 170

<Test Signal>

Inner pattern

(255gray,80IRE)

Medium

Min : 200

Warm

Min :

260

Operating

Condition

Sync (H/V)

or

V

ideo

EUT

(MSPG6100)

LED

(SET)

Wattage

(W)

Sleep

mode

Off/Off

Off

White blinking

1.2W

Off

mode

-

-

Off

0.3

No.

Adjustment contents CMD(h

ex)

ADR

VA

L(hex)

Explanation

1

EEPROM ALL INITIA

L

E

4

00

00

adjustment Initiali

z

ation

2

EEPROM READ

E7

Slave add

At EEPROM Read

3

EEPROM WRITE

E8

Slave add

Data

Write data at EEPROM

4

R GAIN

1

6

00

00-

64

Tune Gain

5

G GAIN

18

00

00-

64

6

B GAIN

00

00-

64

7

BRIGHT(Backlight)

10

00

00-

64

Tune Analog Bright

8

FACTORY RESET

F0

00

0

Factory reset

9

AUTO_COLOR_ADJ

UST

F1

00

0

AUTO COLOR Tuning

0:Auto color

10

COLOR_MODE_CH

ANGE

F2

00

1

WARM(

6500

K)

2

COOL(9300K)

11

Elapsed time Clear

E9

00

00

Aging off &Clear elapse

d time

12

Aging On/Off

F3

00

FF/00

FF:ON / 00:OFF

13

Input Select

F

4

00

0xD0

1:DisplayPort

0x90

2:HDMI1

0x91

3:HDMI2

0xD1

4

:Thunderbolt (UC98 o

nly)

1

4

SYSTEM RESET

F5

00

00

RestartSystem

15

Select Language

6

8

00

0x00

~

0x0F

00:English,

01:German

02:French

03:Spanish

0

4

:Italian

05:Swedish,

0

6

:Finnish

07:Portuguese

08:Bra

z

il

09:Polish

0A:Russian

0B:Greek

0C:Ukrainian

0D:Chinese

0E:Japanese

0F:Korean

EDID SN UPDATE

0x77

0

0x01

~

0x02

0x01 :HDMI1

0x02 :HDMI2

APD command

0xF7

00

0x00

~

0x01

0x00:OFF

0x01:ON

Module name

LM

34

0UW3

Summary of Contents for 34UC80

Page 18: ......