- 12 -

LGE Internal Use Only

Copyright ©

LG Electronics. Inc. All rights reserved.

Only for training and service purposes

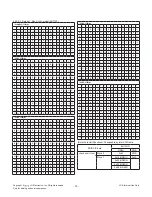

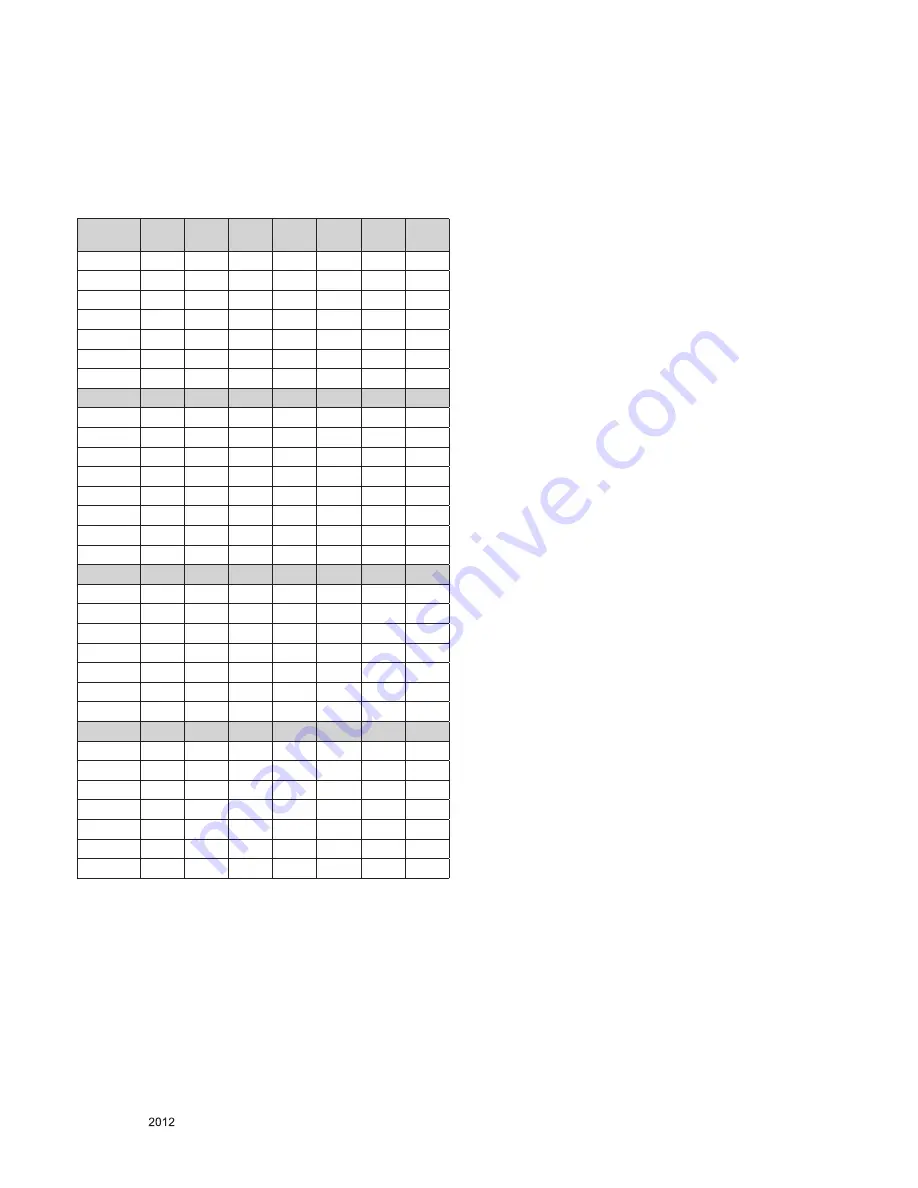

4.4. Input tool option.

Adjust tool option refer to the BOM.

▪ Tool Option Input : PCBA Check Process

▪ Area Option Input : Set Assembly Process

*** Tool Option table

MODEL

32LS5700

(AUO)

32LS5700 42LS5700 47LS5700 55LS5700

Tool Option1

4452

356

358

359

361

Tool Option2

9557

9557

9557

9557

9557

Tool Option3

845

845

845

845

845

Tool Option4

12910

12910

12908

12908

12908

Tool Option5

4765

21021

21021

21021

21021

Tool Option6

1321

1321

1321

1321

1321

Tool Option7

4651

555

4907

4395

4395

MODEL

32LM6200 37LM6200 42LM6200 47LM6200 55LM6200 65LM6200

(AUO)

Tool Option1

116

117

118

119

121

36987

Tool Option2

9557

9557

9557

9557

9557

9557

Tool Option3

17229

17229

17229

17229

17229

17229

Tool Option4

12910

12910

12908

12908

12908

12910

Tool Option5

23069

23069

23069

23069

23069

6685

Tool Option6

1321

1321

1321

1321

1321

1321

Tool Option7

555

555

4907

4395

4395

12311

MODEL

32LM6400 42LM6400 47LM6400 55LM6400 42LM6600 42LM6690 47LM6690

Tool Option1

33156

33158

33159

33161

32934

32934

32935

Tool Option2

42325

42325

42325

42325

42325

42325

42325

Tool Option3

17229

17229

17229

17229

17229

17229

17229

Tool Option4

12911

12909

12909

12909

12909

12909

12909

Tool Option5

23191

23191

23191

23191

23191

23191

23191

Tool Option6

1321

1321

1321

1321

1321

1321

1321

Tool Option7

1963

6059

6059

6059

6059

6059

6059

MODEL

42LM6700 47LM6700 55LM6700 42LM7600 47LM7600 55LM7600 42LM7600

Tool Option1

32950

32951

32953

32966

32967

32969

32966

Tool Option2

42325

42325

42325

42325

42325

42325

42325

Tool Option3

17229

17229

17229

17229

17229

17229

17229

Tool Option4

12909

12909

12909

12909

12909

12909

12909

Tool Option5

23191

23191

23191

23191

23191

23191

23191

Tool Option6

1321

1321

1321

1321

1321

1321

1321

Tool Option7

6059

6059

6059

13355

13611

13611

13355

After Input Tool Option and AC off

Before PCBA check, you have to change the Tool option and

have to AC off/on (Plug out and in)

(If missing this process, set can operate abnormally)

4.4.1. Profile

Must be changed the option value because being different with

some setting value depend on module maker, inch and market

4.4.2. Equipment

Adjustment remote control

4.4.3. Adjustment method

The input methods are same as other chassis.(Use ADJ Key

on the Adjust Remocon.)

(If not changed the option, the input menu can differ the model

spec.)

Refer to Job Expression of each main chassis ass’y

(EBTxxxxxxxx) for Option value

Caution : Don’t Press “IN-STOP” key after completing the

function inspection.

4.5. EDID D/L method

Recommend that don’t connect HDMI and RGB(D-SUB) cable

when downloading the EDID.

If not possible, recommend that connect the MSPG equipment.

There are two methods of downloading the edid data

4.5.1. 1st Method

EDID datas are automatically downloaded when adjusting the

Tool Options.

Automatically downloaded when pushing the enter key after

adjusting the tool option5.

It takes about 2seconds

4.5.2. 2nd Method

● Caution : Must be checked that the tool option is right or not.

If tool option is wrong, hdmi edid data could not be

downloaded well.

1) Press the ADJ key

2) Move to the 10. EDID D/L and Press the right direction

key(►)

3) Press the right direction key(►) at Start.

4) After about a few seconds, appear “Waiting..” => “OK”, then

compele.

4.5.3. RS-232C command Method

1) Command : AE 00 10

● Caution : Don’t connect HDMI and RGB(D-SUB) cable when

downloading the EDID.

If the cables are connected, Downloading of edid

could be failed

Summary of Contents for 42LM6700

Page 77: ......