- 15 -

W

Auto adjustment Map(RS-232C)

9-3. Adjustment of White Balance

(For Manual adjustment)

O

Operate the zero-calibration of the CA-100, then stick

sensor to PDP module surface when you adjust.

O

For manual adjustment, it is also possible by the following

sequence.

1) Select white pattern of heat-run mode by pressing power on

key on remote control for adjustment then operate heat run

more than 15 minutes.

2) As below Fig.9, Supply 216Level (85 IRE) full screen

pattern to Video input.

(Input 50Hz, 42PC1DA : AV3/AV4 Input)

3) Press the TV/AV KEY on R/C for converting input mode.

4) Set the PSM to Standard mode in Picture menu.

5) Enter the White Balance adjustment mode by pressing the

INSTART key twice(White Balance) on R/C.

6) Stick sensor to center of the screen and select each items

(Red/Green/Blue Gain and Offset) using

D

/

E

(CH +/-) key

on R/C.

7) Adjust Only High Light with R Gain/ B Gain using

F

/

G

(VOL+/-) key on R/C.

8) Adjust it until color coordination becomes as below.

(Initially, R/G/B gain and R/G/B offset values are fixed as

below

Red Gain : 82,

Green Gain : 80,

Blue Gain : 86

Red Offset : 7D, Green Offset : 7E,

Blue Offset : 80)

[PD61A]-VGA 42”, XGA 42”,50” Module

Brightness :

High Light :

80 ± 20cd/m2

Color-Coordinate :

High Light :

X : 0.285 ± 0.003

Y : 0.290 ± 0.003

Color Temperature : 9,300°K ± 500°K

9) When adjustment is completed, Exit adjustment mode using

EXIT key on R/C.

10. Auto Component Color Balance

10-1. Requirement

- It is very import to use correct adjustment pattern like Fig.10.

V

Within the pattern, color sequence should be aligned

: W-Y-C-G-M-R-BLUE-BLACK.

(If color sequence is reversed(Black -> ... > White), reverse

the pattern with REV key, when using Master pattern

generator like MSPG-925)

V

If Minimum Black Level and/or Maximum White Level is not

correct, select 100% Color Bar Pattern.

10-2. Required Test Equipment

1) Remote controller for adjustment.

2) 802F Pattern Generator.

(Which has 720p Ypbpr output with Standard(0.7Vpp)

Vertical 100% Color Bar Pattern as Fig.10)

10-3. Method of auto component color balance

1) Input the Component 720p 100% Color Bar signal into

Component1 or Component2.

2) Set the PSM to Standard mode in Picture menu.

3) Press INSTART key on R/C for adjustment.

4) Press the

G

(Vol. +) key operate to set, then it becomes

automatically.

5) Auto-RGB OK means complete adjustment.

11. Auto RGB Color Balance

11-1. Requirement

- It is very import to use correct adjustment pattern like fig.11

V

Within the pattern, color sequence should be aligned

: W-Y-C-G-M-R-BLUE-BLACK.

(If color sequence is reversed(Black -> ... > White), reverse

the pattern with REV key, when using Master pattern

generator like MSPG-925)

V

If Minimum Black Level and/or Maximum White Level is not

correct, Do select 100% Color Bar Pattern.

11-2. Required Test Equipment

1) Remote controller for adjustment.

2) 802F Pattern Generator, Master(MSPG-925FA), etc.

(Which has XGA 60Hz PC Format output with standard

(0.7Vpp) 100% Color Bar Pattern as Fig.11)

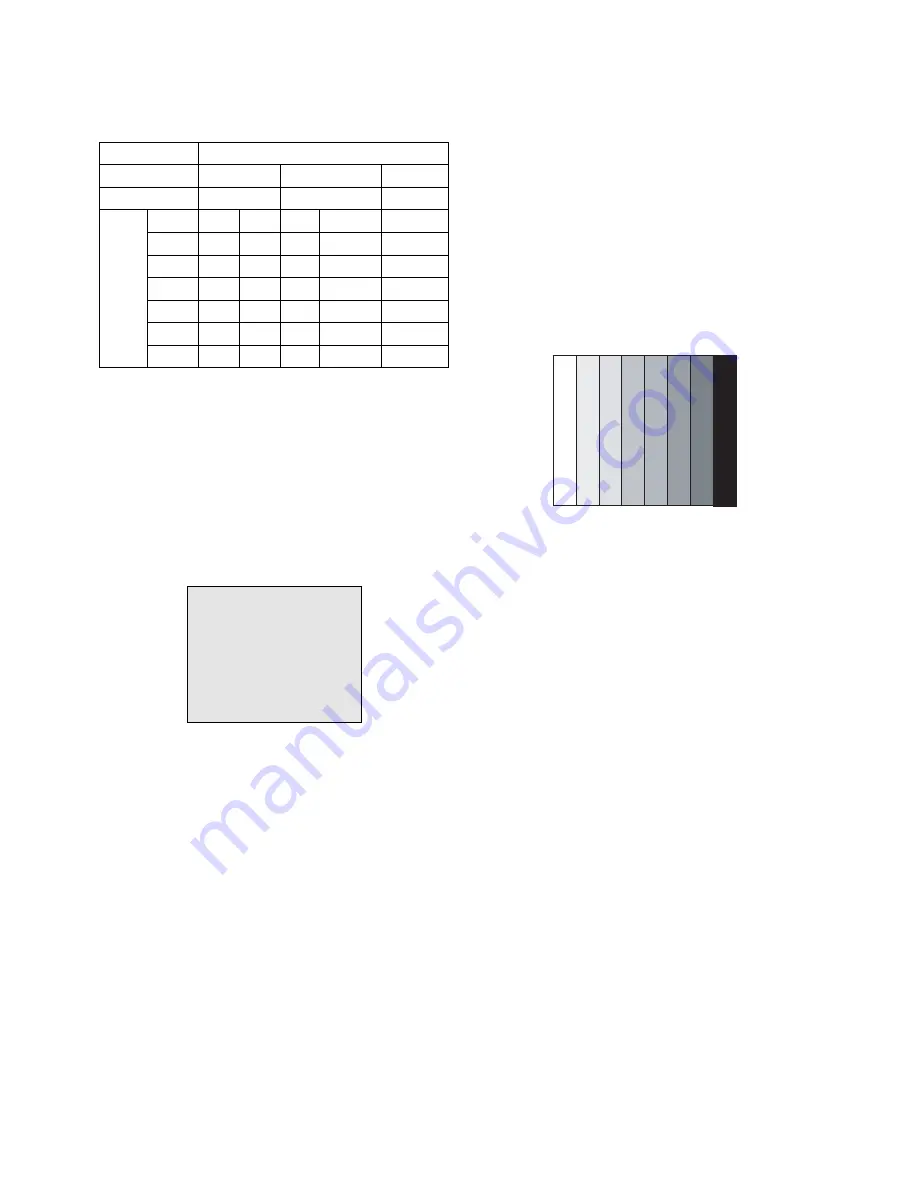

(Fig. 10) Auto Component Color Balance Test Pattern

(Fig. 9) Pattern for Adjustment of White Balance

216 Level (85 IRE)

216 Level (85 IRE)

Type

Baud Rate

115200

Index

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Data bit

8

Cmd1 Cmd2

j

a

j

b

j

c

j

d

j

e

j

f

Stop bit

1

Parity

NONE

PD61A : 42PC1DV-EC

Protocol

Setting

Data

Min Value

00(00)

00(00)

00(00)

00(00)

00(00)

00(00)

Max Value

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

255(FF)

Summary of Contents for 42PC1DA Series

Page 22: ... 22 PRINTED CIRCUIT BOARD MAIN TOP ...

Page 23: ... 23 MAIN BOTTOM ...

Page 24: ... 24 AV TOP AV BOTTOM ...

Page 25: ... 25 CONTROL PRE AMP SIDE A V ...

Page 27: ...MEMO 27 ...

Page 46: ...MAIN Control Pre AMP ...

Page 47: ......