89

Plasma Fall 2008 42PG20

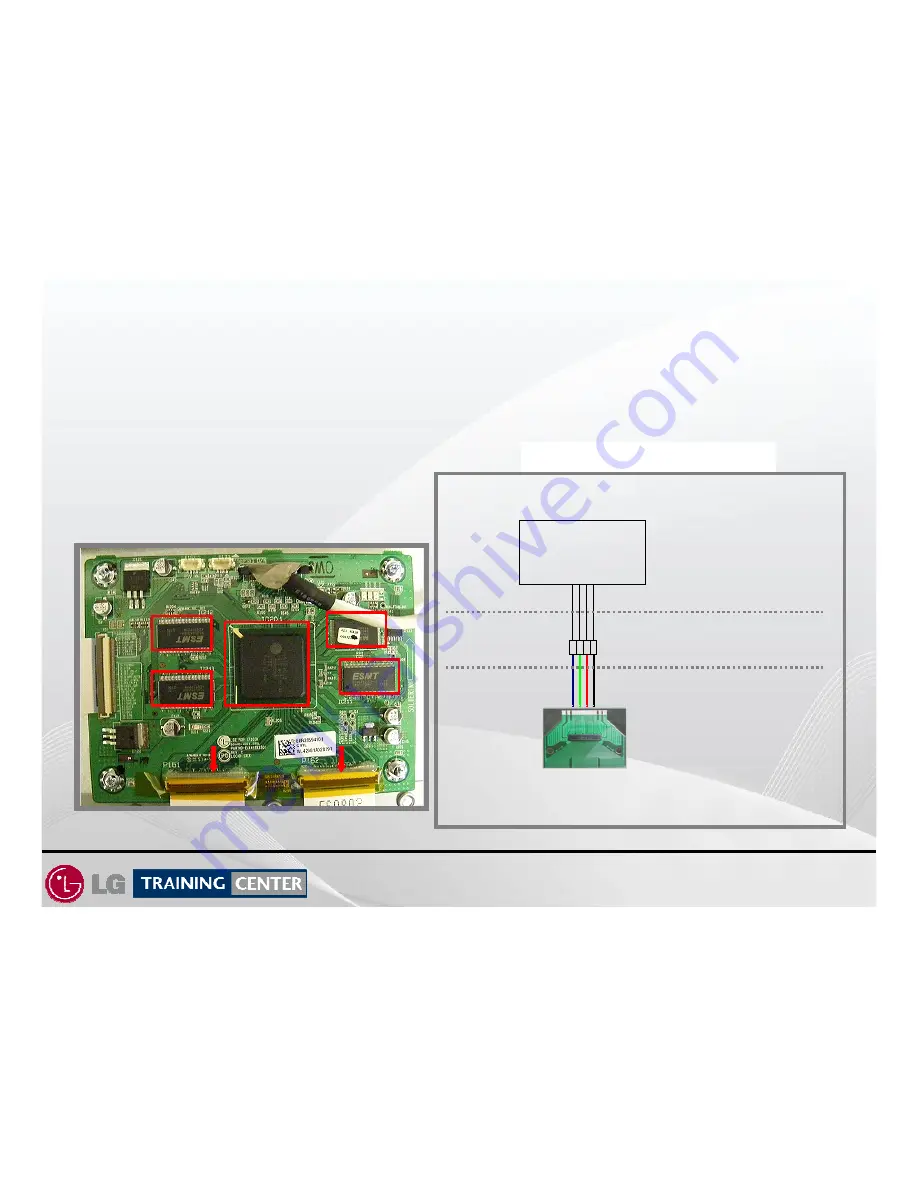

This Picture shows Signal Flow Distribution to help determine the

failure depending on where the it shows on the screen.

The Control Board supplies Video Signals to the TCP (Tape Carrier Package) ICs.

If there is a bar defect on the screen, it could be a Control Board problem.

MCM

16 line

Resistor Array

192 Lines output Total

Diagram of Control Board

Control Board to X Board

Address Signal Flow

IC201

Control PWB Signal Block

Control PWB Signal Block

MCM

DRAM

DRAM

DRAM

EEPROM

2 Buffer

Outputs

per TCP

CONTROL PWB

X-DRIVE PWB

PANEL

96 Lines per Buffer

Summary of Contents for 42PG20 Series

Page 17: ...17 Plasma Fall 2008 42PG20 Rear Input Jacks Rear Input Jacks ...

Page 18: ...18 Plasma Fall 2008 42PG20 42PG20 Dimensions 42PG20 Dimensions ...

Page 45: ...45 Plasma Fall 2008 42PG20 STATIC TEST UNDER LOAD LIGHT BULB TEST ...

Page 98: ...98 Plasma Fall 2008 42PG20 TCP Tape TCP Tape Carrier Carrier Package Package ...