- 7 -

LGE Internal Use Only

Copyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

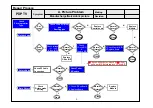

3) Click the Config button and Change speed

E2PROM Device setting : over the 350Khz

4) Read and write bin file

Click “(1)Read” tab, and then load download

file(XXXX.bin) by clicking “Read”.

5) Click “Auto(2)” tab and set as below

6) Click “Run(3)”.

7) After downloading, check “OK(4)” message.

3-6. Download Method (By using USB

Memory Stick)

* Caution

- Using ‘power on’ button of the control R/C, power on TV.

- USB file (EPK) version must be bigger than downloaded

version of main B/D.

- It should be only one SW binary file in USB Stick

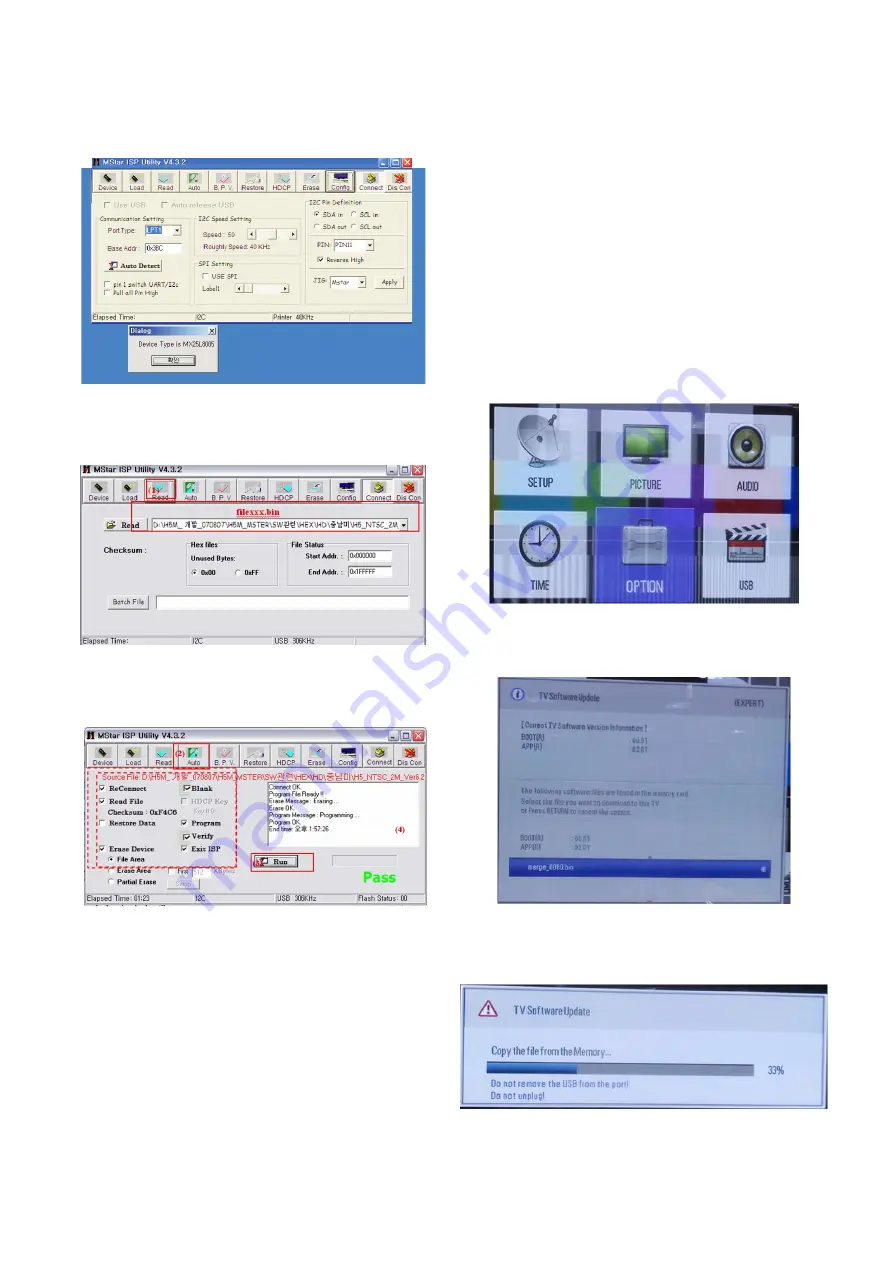

(1) Using ‘Power ON’ button of the control R/C, Power on TV.

(2) Insert the USB memory stick to the SET.

(3) Display USB loding message then, push the ‘Exit’ Key of

control R/C

(4) Push the ‘MENU’ Key and move the cusor ‘OPTION’ of

OSD ( Fig. 1)

* Caution : Don’t push the ‘OK’ key.Just cusor is on the

‘OPTION’ menu.

(5) Push the “7” key of control R/C continuously.

Then, Display “TV Software Update” Pop-up menu. (Fig. 2)

(6) Select SW file (XXXX.bin) you want, push the “OK” Key.

(7) S/W download process is excuted automatically.

( Fig. 1)

( Fig. 2)

Summary of Contents for 42PT350R

Page 18: ......