Test Running

Installation Manual

33

ENGLISH

Test Running

1. Check that all tubing and wiring have been properly connected.

2. Check that the gas and liquid side service valves are fully open.

Prepare remote control

Remove the battery cover by pulling it according

to the arrow direction.

Insert new batteries making sure that the (+)

and (–) of battery are installed correctly.

Reattach the cover by pushing it back into

position.

:

• Use 2 AAA(1.5volt) batteries. Do not use

rechargeable batteries.

• Remove the batteries from the remote control

if the system is not going to be used for a long

time.

Evaluation of the performance

Operate unit for 15~20 minutes, then check the

system refrigerant charge:

1. Measure the pressure of the gas side service

valve.

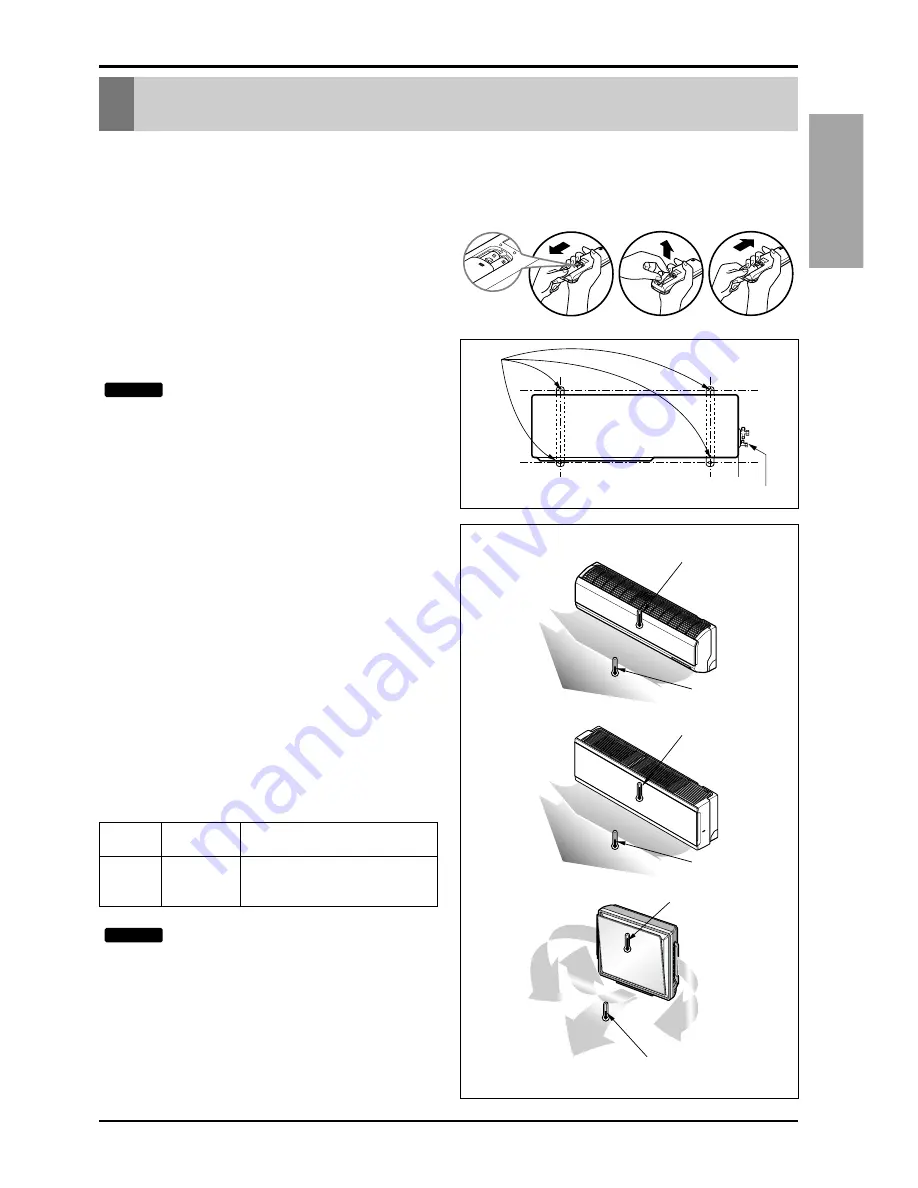

2. Measure the temperature of the intake and

discharge of air.

3. Ensure the difference between the intake

temperature and the discharge is more than

8°C

4. For reference, the gas side pressure of

optimum condition is as below.(Cooling)

: If the actual pressure are higher than

shown, the system is most likely over-

charged, and charge should be

removed. If the actual pressure are

lower than shown, the system is most

likely undercharged, and charge should

be added.

The air conditioner is now ready for use.

NOTICE

NOTICE

Discharge

temperature

Discharge air

Intake temperature

Discharge

temperature

Discharge air

Intake temperature

Discharge

temperature

Discharge air

Intake temperature

Bolt

Tubing connection

R410A

35°C (95°F)

8.5~9.5kg/cm

2

G(120~135 P.S.I.G.)

Outside ambient

TEMP.

Refrigerant

The pressure of the gas side

service valve.

Summary of Contents for A3UW186FA3

Page 37: ......