20

'XHWRRXUSROLF\RIFRQWLQXRXVSURGXFWLQQRYDWLRQVRPHVSHFL¿FDWLRQVPD\FKDQJHZLWKRXWQRWL¿FDWLRQ

/*(OHFWURQLFV86$,QF(QJOHZRRG&OLIIV1-$OOULJKWVUHVHUYHG³/*´LVDUHJLVWHUHGWUDGHPDUNRI/*&RUS

LG

Air-Cooled Cooling Only Inverter Scroll Chiller Installation and Owners’

Manual

PLACEMENT CONSIDERATIONS

Seasonal Wind and Winter Installation Precautions

To ensure the chiller operates properly, certain measures are required in locations where strong cold winds, heavy snowfall, and freezing

temperatures could occur.

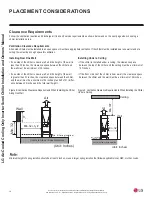

Consider chiller fan operation when installing in snow-prone areas. If the chiller fan is installed below a certain level, it could trigger a high pressure

error within the circuit and cause operation malfunction.

1. Snow could access the air discharge outlet of the condenser and

freeze inside the chiller; in areas with potentially high snowfall

amounts, install a cover over the chiller to prevent snow accumu-

lation on its top.

2. The interior of the chiller could freeze if the air inlet becomes

clogged with snow. Install the chiller in such a way that snow

drifts do not blow into the air inlet, and install a hood to block the

unit from heavy snow. Clear the area of snow around the chiller

heat exchanger.

3. Install the concrete slab or base materials (plus spring isolation)

so that the chiller is 4 inches (102 mm) higher than the accumu-

lated snow (the chiller is to be installed 4 inches [102 mm] above the average accumulated snowfall for the geographical area).

4. If more than 4 inches (102 mm) of snow has accumulated on top of the chiller, remove the snow, and then operate the unit.

5.

The height of the concrete slab or base materials (plus spring isolation) should not exceed the width of the chiller.

6.

Do not install the chiller in an area where heavy snow accumulation could negatively impact chiller operation. Position the chiller in

such a way that the side with the air heat exchanger does not face the direction of the snow (ensure the side with the air heat exchanger

is parallel to snowfall direction). Add a wall high enough to prevent any snow accumulation from being drawn up into the coil side of the

chiller (field installed).

7. If seasonal winds are strong and blow predominately from one direction, chiller capacity could be reduced or load imbalance could occur;

therefore, install the chiller so that the product cycle is not impacted. If that isn’t possible, install a windbreaker, hood, etc. In locations with

strong seasonal winter winds (especially near coastal areas), install a hood, taking into consideration wind direction, that doesn’t block the

suction inlet of the chiller. If the chiller will be directly exposed to seasonal winter winds, field-install a wind baffle (in addition to the hood).

8.

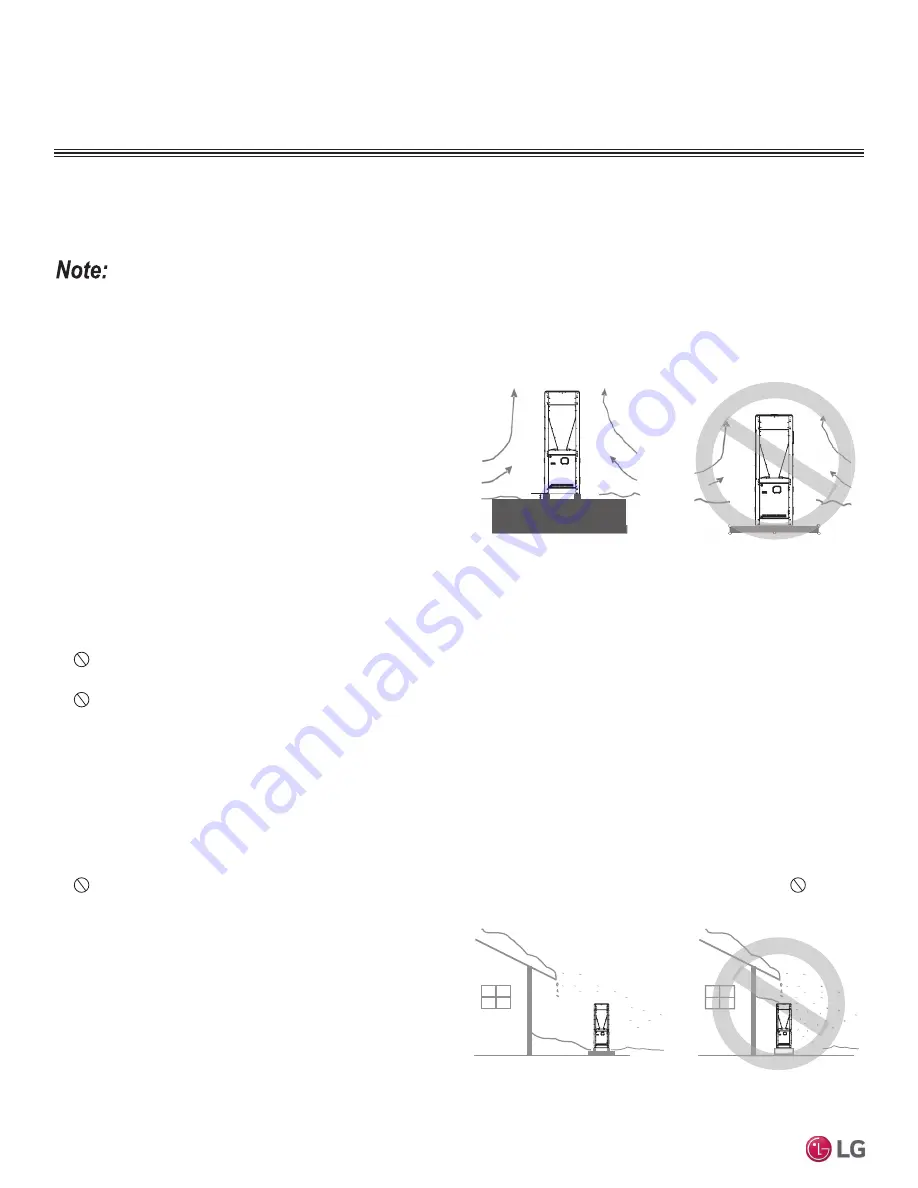

Do not install the chiller near an edge of a rooftop or overhang. Snow can fall off the roof or overhang and into the chiller.

Do not

allow snow to accumulate between the outside wall and the

chiller. If snow accumulates in this location, chiller operation will

malfunction due to reduced airflow.

Min. 4 inches

above snow

accumulation

(Stand plus

Spring Isolation)

Figure 12:

,QVWDOOLQJWKH&KLLJK%DVH)RU2SWLPXP$LUÀRZ

Figure 13: Installing the Chiller Away from Rooftops and Overhangs.