- 65 -

Copyright ©2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Specification ...............................................................................66

2. Functions ....................................................................................67

3. Operation Details........................................................................68

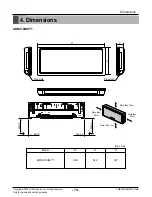

4. Dimensions .................................................................................75

5. Piping Diagrams .........................................................................76

6. Wiring Diagrams .........................................................................77

Art Cool Type(Wide)

Summary of Contents for ARNU07GB1G1

Page 338: ...P NO 3828A24006P FEBRUARY 2009 ...