MULTI V

Modular Heat Pump

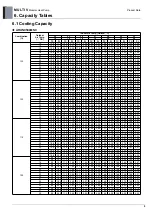

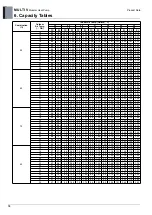

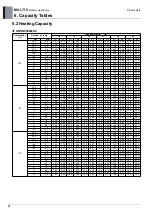

7. Capacity Correction Factor

16

Product Data

Note

1. These figures illustrate the rate of change in capacity of a standard indoor unit system at maximum load under

standard conditions.(Moreover, under partial load conditions there is only a minor deviation from the rate of

change in capacity shown in the above figures.)

2. With this outside unit, evaporating pressure constant control when cooling, and condensing pressure constant

control when heating is carried out.

3. If heat insulation of piping is insufficient, heat loss will become larger and capacity will decrease.

4.

Method of calculating cooling / heating capacity

:

Maximum cooling / heating capacity of outside units

=

cooling / heating capacity of outside units obtained from capacity table

×

capacity correction factor due to piping length to the farthest indoor unit

5.

Equivalent piping length for Y Branch and other pipes

can be calculated with following table.

6. When the equivalent length between Heat Exchanger Module and the farthest indoor unit is 90m or more, the

diameter of main pipe(Compressor Module ~ 1st Branch) must be increased.

• (Liquid and Gas pipes are increased.)

• Refer to the table (Refrigerant pipe diameter from outside unit to first branch) in the '

Installation of outside

units

' part.

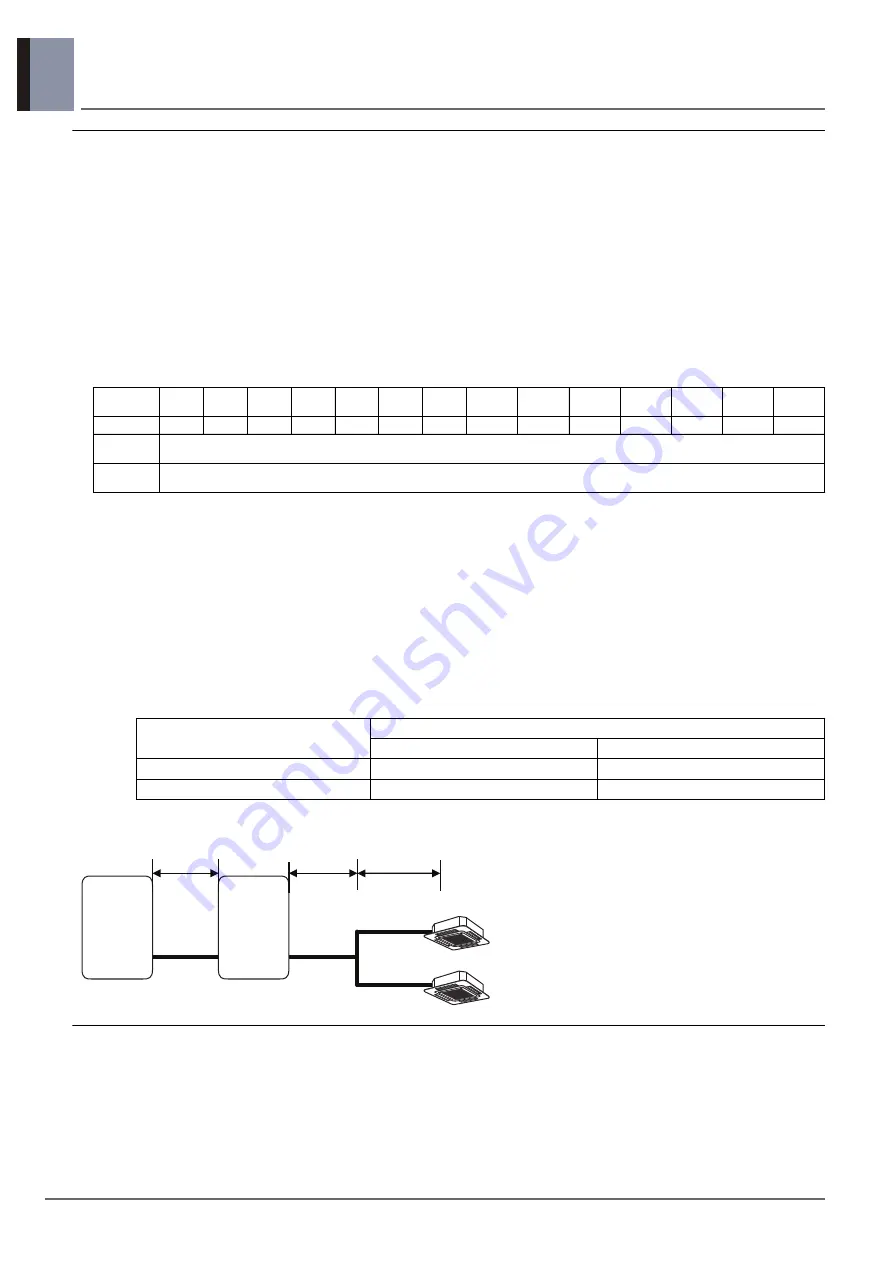

7. Read cooling / heating capacity rate of change in the above figures based on the following equivalent length.

•

Overall equivalent length = L1 + L2 × CF + L3

–

L1 : Equivalent length of main pipe from Heat Exchanger Module to Compressor Module

–

L2 : Equivalent length of main pipe from Compressor Module to 1st Branch

–

L3 : Equivalent length of Branch pipe after 1st Branch

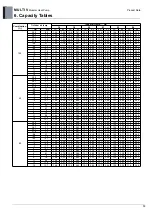

mm

(inch)

Ø6.35

(1/4)

Ø9.52

(3/8)

Ø12.7

(1/2)

Ø15.8

8 (5/8)

Ø19.0

5 (3/4)

Ø22.2

(7/8)

Ø25.4

(1)

Ø28.58

(1-1/8)

Ø31.8

(1-1/4)

Ø34.9

(1-3/8)

Ø38.1

(1-1/2)

Ø41.3

(1-5/8)

Ø44.5

(1-3/4)

Ø53.98

(2-1/8)

Elbow (m)

0.16

0.18

0.2

0.25

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0.7

0.75

0.85

Y Branch

(m)

0.5

Header

(m)

1

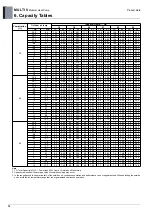

Rate of change

(object piping)

Correction factor

standard size

size increase

Cooling(Gas pipe)

1

0.5

Heating(Liquid pipe)

1

0.2

• In case of increased piping installation

– (Cooling) Overall equivalent length

= 30 m + 30 × 0.5 + 40 m = 85 m

– (Heating) Overall equivalent length

= 30 m + 30 × 0.2 + 40 m = 76 m

• The rate of change

– Cooling capacity when HU

= 0m is thus approximately 0.89

– Heating capacity when HU

= 0m is thus approximately 1.00

Comp.

Module

30m

30m

Equivalent length

40m

Branch

Indoor Unit

Indoor Unit

Gas pipe

Liquid pipe

HEX

Module

Equivalent length

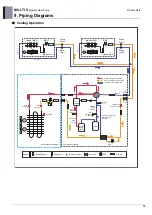

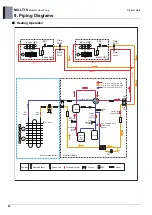

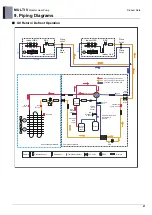

Summary of Contents for ARUN050GME0

Page 1: ...Modular Heat Pump R410A 50Hz 5CVD0 01A P No MFL67474053 ...

Page 2: ...MULTI V S Modular Heat Pump General information Product Data Installation Guide ...

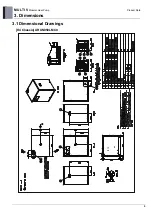

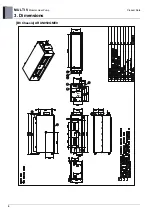

Page 11: ...MULTI V Modular Heat Pump 3 Dimensions 6 Product Data GG B8 Chassis ARUN050GME0 ...

Page 27: ...22 MULTI V Modular Heat Pump Product Data 10 Wiring Diagrams ARUN050LMC0 ARUN050GME0 ...