6 Room Air Conditioner

Specfications

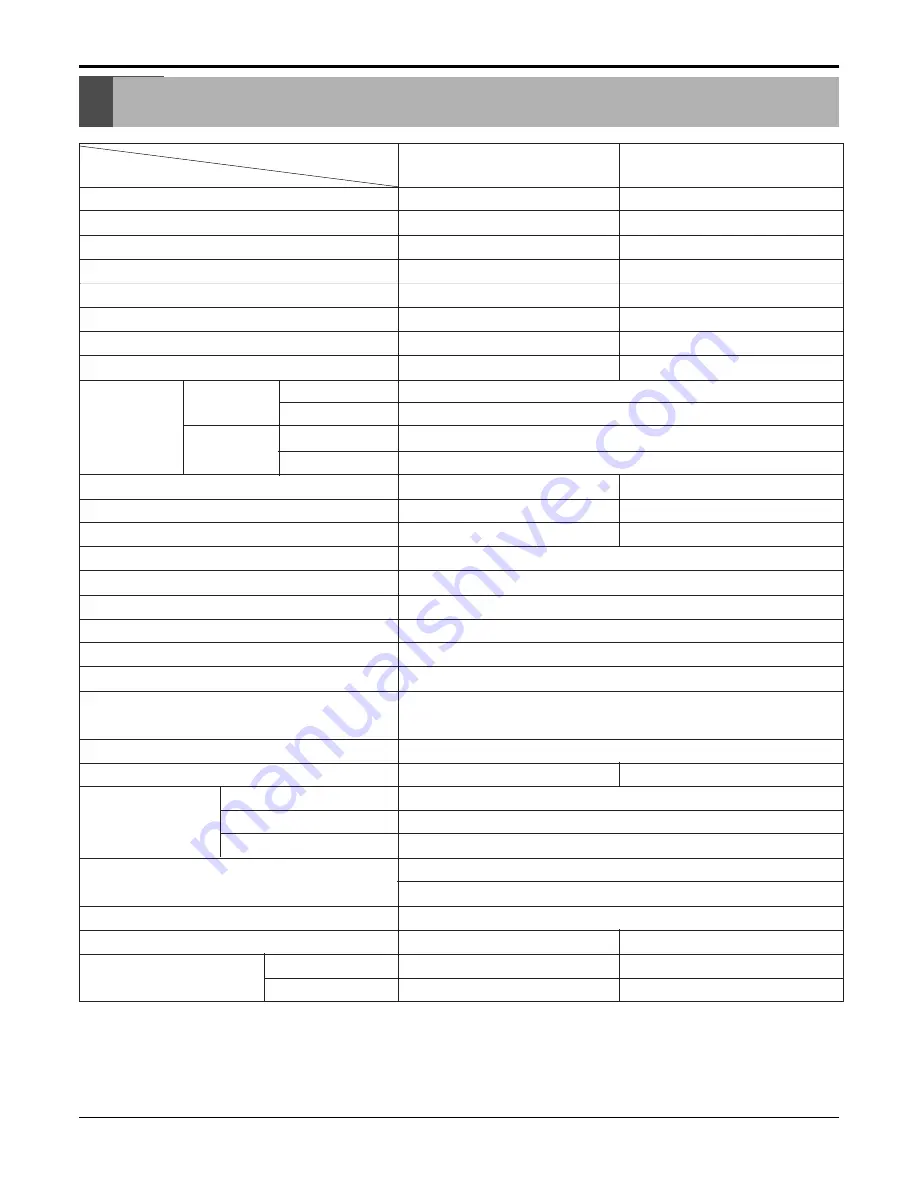

Product Specifications

POWER SUPPLY

COOLING CAPACITY

(Btu/h)

INPUT

(W)

RUNNING CURRENT

(A)

E.E.R

(BTU/W.h)

HEATING CAPACITY

(Btu/h)

INPUT

(W)

RUNNING CURRENT

(A)

INDOOR(°C)

OUTDOOR(°C)

INDOOR(°C)

OUTDOOR(°C)

REFRIGERANT (R-22) CHARGE

EVAPORATOR

CONDENSER

FAN, INDOOR

FAN, OUTDOOR

FAN SPEEDS, FAN/COOLING/HEATING

FAN MOTOR

OPERATION CONTROL

ROOM TEMP. CONTROL

AIR DIRECTION CONTROL

CONSTRUCTION

ELECTRIC HEATER

COMPRESSOR

PROTECTOR

FAN MOTOR

ELECTRIC HEATER

POWER CORD

DRAIN SYSTEM

NET WEIGHT

(lbs/kg)

OUTSIDE DIMENSION

(inch)

(W x H x D)

(mm)

1Ø,115V, 60Hz

1Ø, 208/230V, 60Hz

6,900

11,500/12,000

710

1,170/1,220

6.6

5.5/5.8

9.7

9.8/9.8

3850

9,200/11,200

1,260

2,900/3,500

11.0

14.0/15.3

26.7 (DB)* 19.4 (WB)**

35 (DB)* 23.9 (WB)**

21.1 (DB)* 15.6 (DB)**

8.3 (DB)* 6.1 (DB)**

385(13.6 oz)

605(21.3 oz)

2ROW 14STACKS

2ROW 13STACKS

2ROW 16STACKS

2ROW 17STACKS

BLOWER

PROPELLER TYPE FAN WITH SLINGER-RING

1 / 2 / 2

6 POLES

TOUCH PANEL

THERMISTOR

VERTICAL LOUVER(RIGHT&LEFT)

HORIZONTAL LOUVER(UP&DOWN)

SLIDE IN-OUT CHASSIS

1.2KW, 115V

3.5KW, 230V

OVERLOAD PROTECTOR

INTERNAL THERMAL PROTECTOR

FUSE LINK, BIMETAL THERMOSTAT

1.6m(3 WIRE WITH GROUNDING)

ATTACHMENT PLUG(CORD-CONNECTED TYPE)

DRAIN PIPE OR SPLASHED BY FAN SLINGER

60/27

87/39

18 X 13

7

/

8

X 20

11

/

16

23

5

/

8

X 14

31

/

22

X 22

5

/

16

470 X 353 X 525

600 X 380 X 525

REG-71A

REG-123A

MODELS

ITEMS

OPERATING

CONDITION

COOLING

HEATING

* DB:Dry Bulb

** WB:Wet Bulb

NOTE: Please refer to Label Quality on the produst since this specification may be changed for improving performance.