5

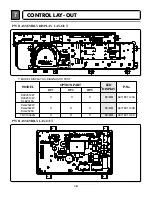

Temperature

Moisture

High/Low/Off

Sensor

3

124/144

Door Trim

Top Plate

Color

Blue White

Silver

Painted

Blue White

Titaium

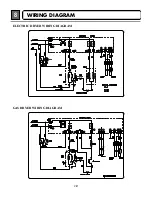

120V/240V 60Hz (26A)

POWER SUPPLY

LAMP

HEATER

MOTOR

3

5

7.0 cu.ft.

Electronic

GAS VALVE

5400W (22.5A)

5

250W (4.5A)

15 W (125mA)

13 W (110mA) x 2

ELECTRICITY

CONSUMPTION

Material &

Finish

DLE2514W

DLG2524W

Chrom

DLE2515S

DLG2525S

DLE2512W

DLG2522W

TD-V10062G

ITEM

Child Lock

Reversible Door

Interior Light

Product (WxHxD)

Packing (WxHxD)

Sound levels

Dryer Rack

Drum

No. of Dry Levels

No. of Dry Options

No. of Programs

DRUM CAPACITY

CONTROL TYPE

No. of Temperature Controls

Weight (lbs) - Net/Gross

AC 120V (GAS MODEL)

AC 240V (ELECTRIC MODEL)

Electrode sensor

Thermistor

AC 120V

AC 120V

REMARK

Available

Available

Available

Available

Avaiable

Avaiable

27" x 38

3/

4

" x 29

5/

8

"

29

1/

2

" x 44

3/

4

x 30

3/

4

Double Coated Steel