- 46 -

- 46 -

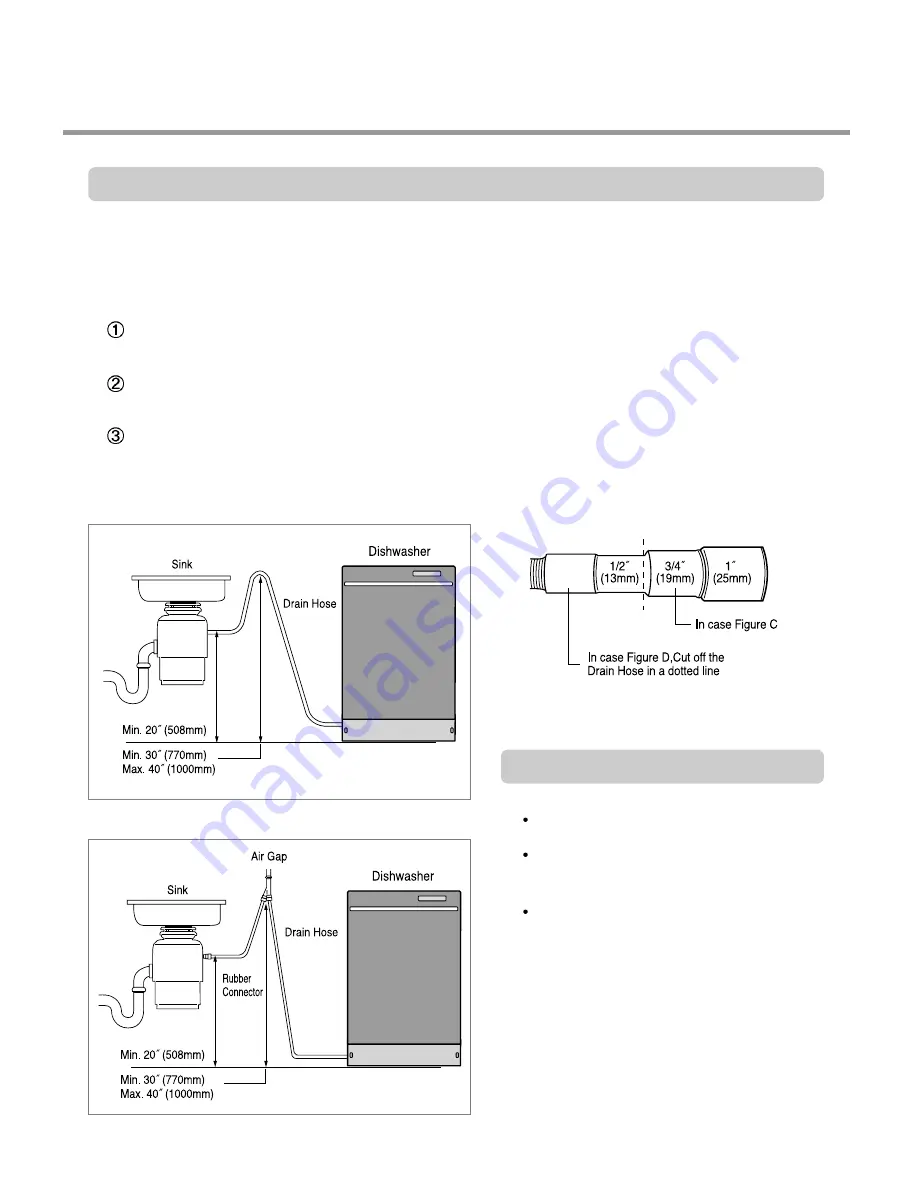

Step 6: DRAIN LINE CONNECTION

1. If the end of the drain hose does not fit to the drain line, use an adapter (not supplied) that

must be resistant to heat and detergent and may be obtained from a plumbing shop.

2. There are 2 typical connections as shown in Figures C & D.

There may be other options than shown here for connection the drain hose. The drain

connection must meet local plumbing regulations.

The S trap spigot must be drilled out cleanly and free of obstruction to its maximum

internal diameter, if used for drainage.

To prevent syphoning, one of the following instruction methods must be followed:

Follow local codes and ordinances.

Do not exceed 10 ft. (3m) distance

to drain.

Do not connect drain lines from

other devices to the dishwasher

drain hose.

Drain Requirements

Figure C: Connection to Disposer or waste Tee.

Figure D: Connection to Air Gap.

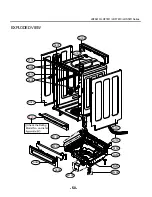

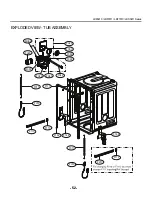

Summary of Contents for DF6810

Page 5: ... 6 1 7811 7810 6810 serise 3 WIRING DIAGRAM 2 8812 serise ...

Page 24: ... 25 Program chart 6 4 LDF 6810 01 Series LDF 6810 02 Series ...

Page 69: ... 70 70 MEMO ...

Page 70: ... 71 MEMO ...

Page 71: ...P No MFL37554801 ...