—3—

1. PREFACE

This Service Manual provides various service information, containing the mechanical and electrical parts etc.

This dehumidifier was manufactured and assembled under the strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precaution prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

• Disconnect power supply before servicing or replacing any electrical or non-electrical component.

• Do not, under any circumstances, cut off the grounding prong or alter the plug in any manner.

1.2 FEATURES

• High efficiency

• Quiet

• Adjustable humidistat

• Hot gas defrost

• Automatic shut-off

• Water-full indicator light

• Easy roll casters

• Removable & large capacity bucket

• Washable air filter

• Fan speed: High/Low 2 fan speeds

• Drain hose connection.

• Power ON/OFF indicator light.

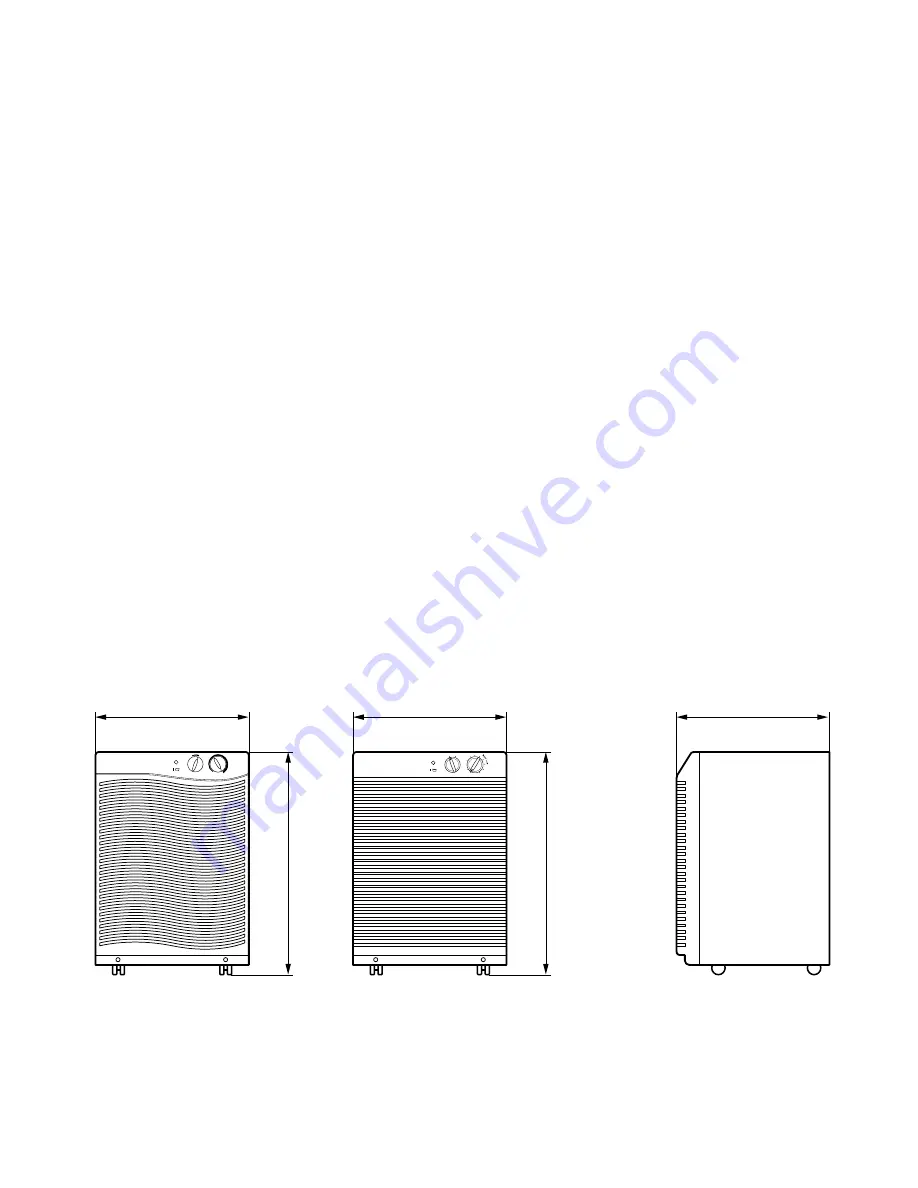

1.3 DIMENSIONS (mm/in)

320 (12

9/16

)

340 (13

3/8

)

530 (20

13/16

)

320 (12

9/16

)

530 (20

13/16

)

High

Low

8

Humidity Control

Fan Speed

O

1

2

3

4

5

6

7

9

Max.

Lo

w

Hig

h

Fan Speed

Dryness Control

Normal

D

ry

n

e

ss

Max

O

• DHA1260HR

• DHA1260HL

• DHA1660HR

• DHA1660HL