SAFETY PRECAUTIONS .................................................................................................................................................... 2

SERVICING PRECAUTIONS ............................................................................................................................................... 3

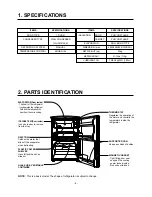

SPECIFICATIONS ................................................................................................................................................................ 4

PARTS IDENTIFICATION .................................................................................................................................................... 4

DISASSEMBLY .................................................................................................................................................................... 5

DOOR ................................................................................................................................................................................ 5

THERMOSTAT .................................................................................................................................................................. 5

COMPRESSOR AND PTC ................................................................................................................................................ 5

CIRCUIT DIAGRAM ............................................................................................................................................................. 6

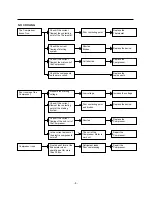

TROUBLESHOOTING .................................................................................................................................................... 7-10

NO COOLING .................................................................................................................................................................... 8

COMPRESSOR AND ANOTHER ELECTRIC COMPONENTS ........................................................................................ 9

PTC ................................................................................................................................................................................. 10

EXPLODED VIEW ........................................................................................................................................................ 11-12

REPLACEMENT PARTS LIST ......................................................................................................................................... 13-

CONTENTS

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. If you use any kind of appliance, check regular current,

voltage and capacity.

5. Don't touch metal products in the freezer with wet

hands. This may cause frostbite.

6. Prevent water from following onto electric elements in

the mechanical parts.

7. Close the top door before opening the bottom door.

Otherwise, you might hit your head when you stand up.

8. When tilting the refrigerator, remove any materials on

the refrigerator, especially the thin plates(ex. Glass

shelf or books.)

9. When servicing the evaporator, wear cotton gloves.

This is to prevent injuries from the sharp evaporator

fins.

10. Leave the disassembly of the refrigerating cycle to a

specialized service center. The gas inside the circuit

may pollute the environment.

SAFETY PRECAUTIONS

- 2 -