3-6

adjust CTL waveform to the following procedures.

A. If is over 2.5 :1, lower the head height.

After turning the height adjust screw counter-clockwise to

adjust its level from 1.5 : 1 to 2 : 1.

Check the tape location at P4. Readjust the TILT.(2:1)

B. If is under 1.5:1, heighten the head height.

After turning the height, adjust the screw clockwise to

adjust its level from 2 : 1 to 2.5 : 1.

Check the tape location of P4. Readjust the TILT.(2:1)

3. Play the standard tape and adjust very carefully the azimuth

screw right and left by using the oscilloscope and level-

meter to maximize the audio sound.

Adjust the azimuth screw & the height adjust screw at the

same time because they have mutual relationship. (Check

CTL again after the adjustment)

*A/C head adjustment order

Height adjust screw->check the TILT->azimuth screw

->check CTL

3.2.3 AUDIO LEVEL CHECKING AND ADJUSTMENT

1. Connect “+” terminal of RMS meter (auto level meter) to J108

on the main PCB Audio output and “-” terminal to GND.

2. Check that if audio level of RMS meter satisfies with the

spec,If audio sound is weak, adjust the A/C head azimuth

screw.

3. Audio level spec

1K :0.5

!

0.1Vrms

6K :1KHz

!

1.5dB

3.3. X-DISTANT/P2,P3 ADJUSTMENT

3.3.1. NECESSARY INSTRUMENT

1. SP PAL TAPE

2. OSCILLOSCOPE

3. 10:1 PROBE : 2 PIECES

4.SPEACIAL DRIVER FOR ADJUSTMENT(P2,P3,X-

DISTANT(NUT),AUDIO(NUT))

5. RMS METER(AUDIO LEVEL METER)

3.3.2. ADJUSTMENT PREPARATION

1.Connect oscilloscope(CH-1) to J123(H/SW) on main PCB.

(Use for trigger of CH-2 )

2.Connect oscilloscope(CH-2) to J158(RF) on main PCB.

(Use waveform of CH-2)

3. Play by inserting SP PAL TAPE. (2hd:normal tape)

4. After the picture is appeared, make initial condition by

pressing the tracking adjustment up(+) button of the remote

controller.

3.3.3. X-DISTANCE ADJUSTMENT

1. Turn the X-distant adjust groove of the deck right and left to

maximize the scope waveform.

2. Check that if waveform satisfies with the linearity by pressing

TRK Up(+) and Down(-) button.

3. Tighten the X-distant adjust screw.

3.3.4. P2/P3(RF LINEARITY) CHECK & ADJUSTMENT

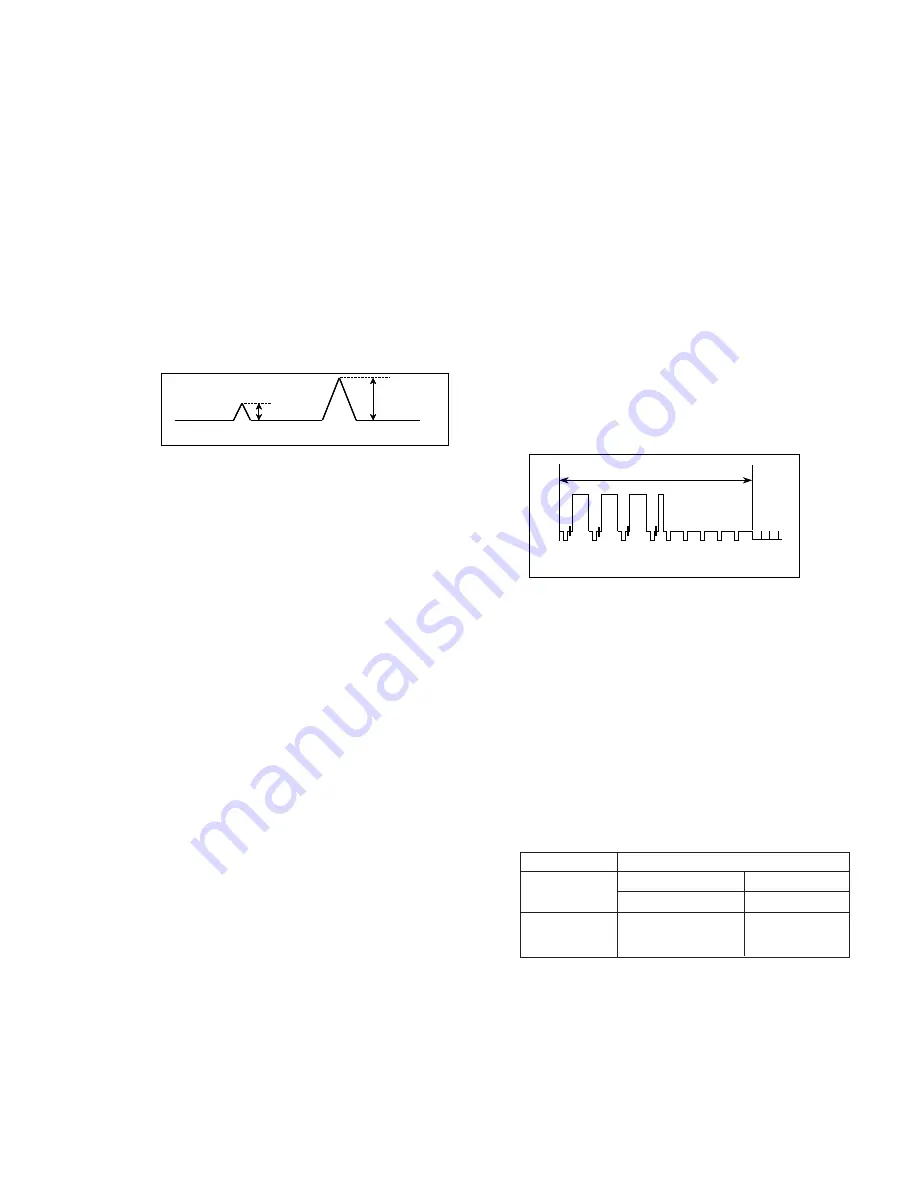

1. Adjust p2 & p3 so that the the RF envelope waveform of the

oscilloscope becomes C in figure 2.

2. Check if the envelope waveform becomes maximum by

pressing TRK Up(+),Down(-) button onestep.

3.4. PG ADJUSTMENT

Adjust it after finishing controlling the Deck.

3.4.1.NECESSARY INSTRUMENT

1. SP PAL TAPE

2. OSCILLOSCOPE

3. 10 : 1 PROBE : 2 PIECES

3.4.2. ADJUSTMENT

1. Insert and play the SP PAL TAPE.

2. Connect the oscilloscope(CH-1) to H/SW(J123) on the main

PCB and trigger in setting the VOL/DIV to 1V range.

3. Connect the oscilloscope(CH-2) to video out(J173) on the

main PCB and set the VOL/DIV to 500mV range.

4. Set the TIME/DIV of oscilloscope to 50us range.

5. Adjust the falling edge(412us

!

20us) of vertical sync in the

video signal by varying VR01.

4.ASSEMBLY LINE ADJUSTMENT

4.1. RF AGC ADJ.( APPLYING THE W/S TUNER )

4.1.1. NECESSARY INSTRUMENT : DIGITAL MULTIMETER

4.1.2. ADJUSTMENT PREPARATION

1. HEAT-RUN at least 15 minutes before adjustment.

2. Input the PAL DIGITAL PATTERN(EU05); The intensity of

electric field for the applied tuner refers to the below data.

3. Connect the DIGITAL MULTIMETER to TP-AGC(J335) of

MAIN1.

4.1.3. ADJUSTMENT

1. Press the SVC key of the transmitter and select

¡

AGC

¡–

of the

SVC MENU using PR+/- key.

2. Adjust it by the below data varying VOL+/- key.

4.2. FOCUS ADJUSTMENT

4.2.1. Receive the standard color signal.

4.2.2. Let the picture be the most clear by the criterion of the

vertical line of it, varying the focus V/R of FBT.

1

2

CTL WAVEFORM

1

2

CTL WAVEFORM

1

2

CTL WAVEFORM

ADJUST PERIOD (6.5H = 412us)

PG ADJUST WAVEFORM

* CAUTION: SET THE TRIGGER MODE OF OSCILLOSCOPE TO DC

ADJUST PERIOD (6.5H = 412us)

PG ADJUST WAVEFORM

* CAUTION: SET THE TRIGGER MODE OF OSCILLOSCOPE TO DC

TUNER

6700VPF009V

6700VMF001H

6700VPF009Q

Electric fields strenth

AGC Voltage

AGC Voltage

70dBu

!

1dBu

2.7

!

0.05Vdc

AGC not adjust.

Setting & Adjustment

Summary of Contents for KE/KL-20/21P32X

Page 6: ...3 9 BLOCK DIAGRAM ...